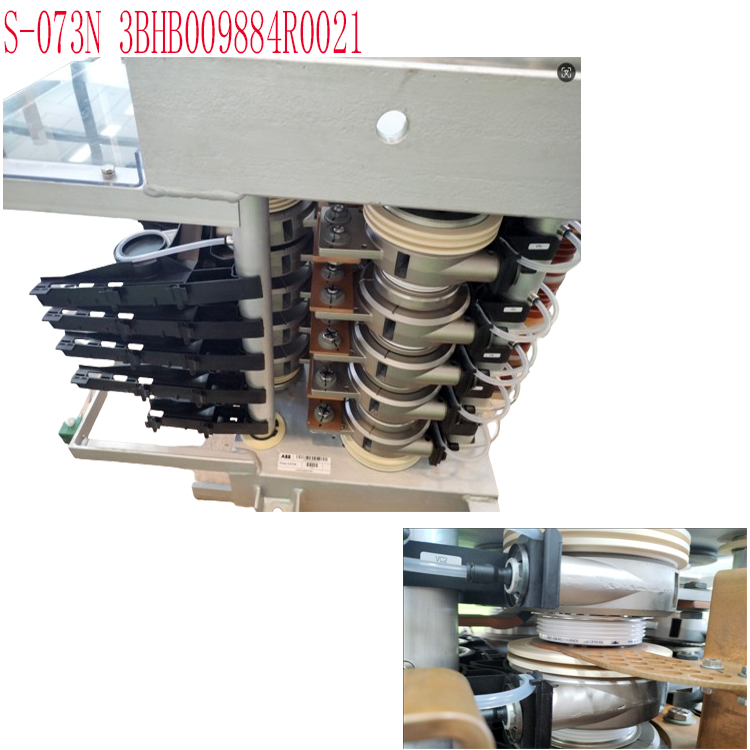

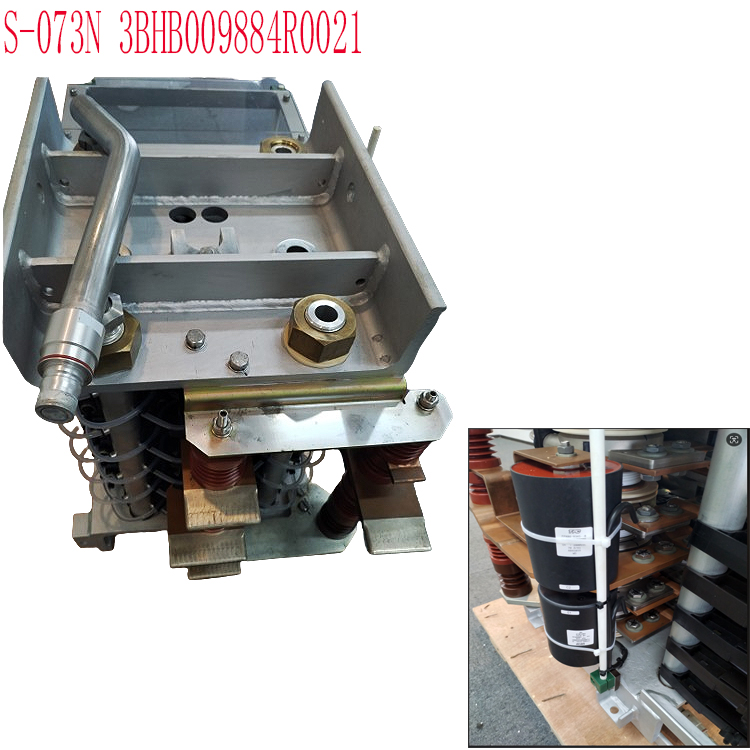

This ABB high-voltage variable frequency phase module is a core component of industrial automation and power systems, primarily used in high-voltage, high-power applications (such as wind power generation, water pump control, motor drives, and energy management). It utilizes IGCT technology to achieve efficient power conversion and precise phase control. It supports communication protocols such as Ethernet/IP and Modbus TCP/IP, enabling seamless integration into complex industrial automation systems.

Usage Requirements

Core Functions and Technical Parameters

Functional Positioning: ABB high-voltage variable frequency phase module is used in high-voltage inverter systems to achieve precise phase control and regulation, ensuring stable power system operation (such as in wind power generation, water pump control, and motor drives).

Technical Specifications:

Power Supply Voltage: 24V DC, Input Voltage Range: 20.4V-28.8V, Output Current: 2A.

Operating Temperature: -20°C-+60°C, Storage Temperature: -40°C-+85°C.

Communication Protocols: Supports Ethernet/IP, Modbus TCP/IP, and is compatible with industrial automation systems.

Protection Rating: IP20 (standard), higher protection ratings available.

Cooling System: Integrated forced air cooling design. Ensure good cabinet ventilation to prevent stray inductance.

Environmental and Installation Requirements

Physical Environment: Requires use in an environment free of strong electromagnetic interference and with controlled humidity (recommended ≤85% RH). Disconnect the power supply during installation, implement anti-static measures, and ensure grounding complies with standards.

Mounting Method: Supports 19-inch rack or DIN rail mounting. Insulators must be used to secure the high-voltage input/output copper busbars.

Electrical Connections: Strictly follow the wiring diagram to avoid incorrect connections that could cause malfunctions.

Accessory Replacement Methods

Advantages of Modular Design

The module utilizes a modular design and supports hot-swappable replacement, reducing downtime. Components such as the communication board, power module, charger, and leakage protector can be replaced individually.

Replacement Steps (using the communication board as an example)

Preparation: Disconnect the power supply and ensure the module is completely de-energized. Wear an anti-static wrist strap and use insulated tools.

Removing the old module: Loosen the retaining screws and disconnect the connecting cables, making sure to mark the cable positions.

Installing the new module: Align the slots and gently push until they snap into place. Reconnect the cables and tighten securely.

Testing and Verification: After powering on, check that communication functions (such as Ethernet/IP connectivity) and output voltage/current meet specifications. Run the self-diagnostic program to confirm that there are no faults.

Other Component Replacements

Power Module: Requires matching the input voltage range (20.4V-28.8V). After replacement, test output stability.

Cooling System: Clean the fan and heat sink regularly. When replacing an aging fan, ensure the new fan matches the specifications.

Sensors/Interfaces: For example, phase detection sensors must be calibrated before use to ensure accuracy.

Specific Component Replacement Examples

Communication Board/Power Module: Refer to the official video tutorial, follow the steps to replace, and verify communication stability.

Cooling System Components: Clean the heat sink regularly and replace aging fans or thermal grease to ensure efficient cooling.

IGCT power devices: Operate only by qualified personnel. Use specialized tools to check device status and avoid accidental contact with high-voltage components.

Maintenance Guide

Daily Maintenance

Appearance Inspection: Inspect the module monthly to confirm the presence of cracks, corrosion, or loose parts. Check the terminals for oxidation, and clean and apply conductive paste if necessary.

Performance Testing: Test output voltage, current harmonics (THD < 3%), communication latency, and other parameters quarterly using specialized equipment to ensure compliance with IEEE 519 standards.

Cooling System: Clean dust from the fan and heat sink every six months and check fan speed. Ensure cabinet ventilation openings are unobstructed.

Troubleshooting

Common Faults: Overvoltage/undervoltage alarms, communication interruption, and overheating protection.

Troubleshooting Steps:

Use the ABB diagnostic tool to read the fault code and locate the problem module.

Check the power input for stability and eliminate external power supply fluctuations.

Test the communication lines (such as Ethernet/IP) for proper connection and update the firmware to the latest version.

Emergency Procedures: If a module overheats, immediately disconnect the power supply and check the cooling system. If communication is interrupted, attempt to restart the module or replace it with a spare module.

Troubleshooting and Warranty

Fault Identification: If phase deviation, communication interruption, or protection triggering occurs, immediately shut down the system for troubleshooting, prioritizing the power supply, wiring, and communication interfaces.

Warranty: Original modules typically come with a one-year warranty, during which quality issues can be repaired or replaced free of charge. Non-original parts may affect system compatibility and warranty coverage.

Professional Support: For complex issues, contact an ABB authorized service provider or technical team to avoid secondary damage caused by unprofessional operation.

Long-Term Maintenance Strategy

Preventive Maintenance: Establish a regular maintenance schedule (e.g., quarterly inspections) and replace wearing parts (e.g., fans, connectors) in advance.

System Upgrades: Module functionality can be expanded or firmware upgraded to maintain system compatibility with the latest standards based on changing industrial needs.

Long-Term Maintenance Recommendations

Firmware Updates: Regularly visit the ABB website to download the latest firmware. Use the Control Builder or Automation Builder tools to upgrade and optimize control algorithms. Spare Parts Management: Stock common accessories (such as communication boards and power modules) to ensure rapid response to faults.

Professional Support: For complex faults, contact ABB Technical Support or refer to official maintenance manuals (such as the “ABB High-Voltage Drive Maintenance Guide”).

Compatibility and Expansion

System Integration: Compatible with ABB 800xA and AC 800M control systems, and supports integration with Siemens and Omron PLCs.

Expansion Modules: Combined with brake resistor units (such as 3BHE021013R0001) and communication modules (such as 3BSE028576R1), a complete high-voltage inverter system can be built.

Application Scenarios: Suitable for high-power, high-reliability scenarios such as wind power generation, water pump control, industrial motor drives, and subway/light rail speed regulation.

Summary: As an ABB high-voltage inverter phase module, the S-093H 3BHB030478R0309 must strictly adhere to the operating environment, installation specifications, and maintenance procedures. Through modular design, intelligent diagnosis and regular maintenance, it can ensure its efficient and stable operation in high-voltage industrial scenarios, extend its service life and reduce the failure rate.

Related product recommendations:

ABB 5SHY3545L0014 3BHB020720R0002

ABB 5SHY4045L0003

5SHY4045L0003 3BHE019719R0101

5SHY4045L0003 3BHB021400 3BHE019719R0101

5SHY3545L0005 336A4954ARP2

KUC321AE HIEE300698R1

KUC711AE 3BHB004661R0001

KUC720AE 3BHB000652R0001

GFD233A101 3BHE022294R0101

GFD563A102 3BHE046836R0102

GF D563 3BHE046836R010

3BHE017628R0002 PPD115A02

PPD517A3011 3BHE041576R3011

PCD232A 3BHE022293R0101

PCD237A101 3BHE028915R0101

PCD230A 3BHE022291R0101

PCD231B 3HHE025541R0101

PCD235C101 3BHE057901R0101

More……

This was really well done. I can tell a lot of thought went into making it clear and user-friendly. Keep up the good work!

Great post! I’m going to share this with a friend.

What i don’t understood is if truth be told how you are now not actually a lot more well-preferred than you might be now. You are very intelligent. You know thus significantly relating to this subject, produced me individually consider it from so many varied angles. Its like men and women aren’t fascinated unless it is something to accomplish with Lady gaga! Your personal stuffs outstanding. At all times deal with it up!

Hello there! Quick question that’s completely off topic. Do you know how to make your site mobile friendly? My site looks weird when browsing from my iphone. I’m trying to find a template or plugin that might be able to fix this issue. If you have any recommendations, please share. Appreciate it!