Description

Many products have not been put on the shelves yet. Please contact us for more products.

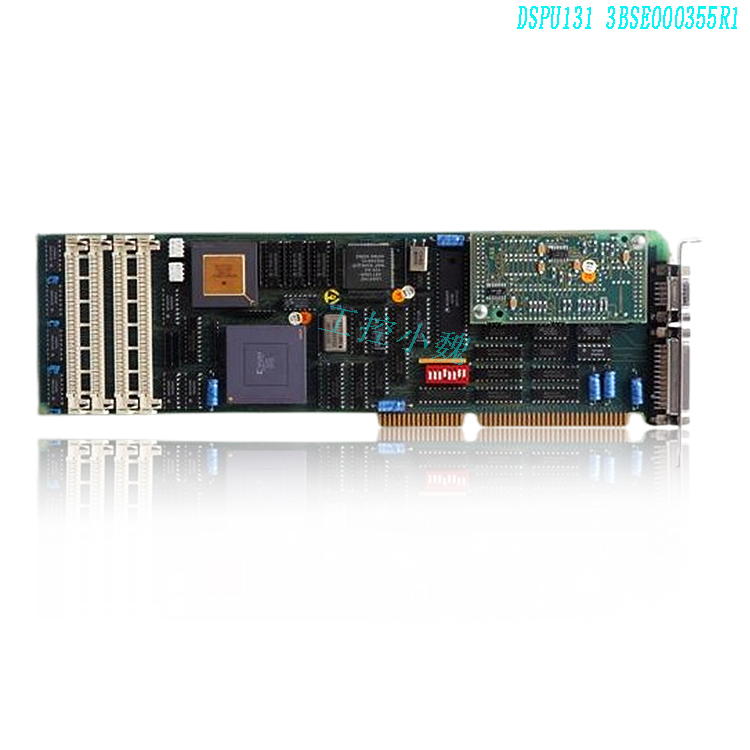

If the product model is inconsistent with the display picture, the model shall prevail. Please contact us for specific product pictures, and we will arrange to take photos in the warehouse for confirmation.

We have 76 shared warehouses around the world, so sometimes it may take several hours to return to you accurately, please understand. Of course, we will respond to your concerns as soon as possible.

Technical features of the ship’s printed circuit board

High reliability design: Ships are in harsh environments such as humidity, salt spray, and vibration for a long time. PCBs need to use three-proof coating (moisture-proof, mildew-proof, and salt spray-proof), high Tg (glass transition temperature) substrates (such as S1000-2M) and hard gold-plated surface treatment to ensure long-term stability. For example, the ship’s main control board adopts a 14-layer board design, and through strict impedance control (such as strict impedance matching of LVDS signal lines) and thermal design (handling currents above 8 amps), high-speed signal transmission and high current carrying capacity are guaranteed.

Complex function integration: Ship PCB needs to integrate multiple processors (such as dual MC8641 solutions), high-speed interfaces (such as PCIE, SRIO) and precision control circuits (such as P.I.D control). For example, the autopilot system PCB needs to implement proportional, integral, and differential control, and suppress slight yaw interference of the ship through filters.

Safety redundancy design: Critical systems (such as power control and fire alarm) use redundant circuit design to ensure that single-point failure does not affect the overall function. For example, the PCB of the rudder failure sensor and the synchronous motor needs to monitor the rudder angle deviation in real time and trigger an alarm when a failure occurs.

Application scenarios of ship printed circuit boards

Navigation and automation control: The PCB carries the signal processing circuits of the gyrocompass, heading linear synchronization device (HDOLS) and autopilot system to realize heading deviation detection and rudder angle command output. For example, the PR-4507 autopilot converts the 400Hz linear synchronization signal of the gyrocompass into a DC signal through the PCB to drive the hydraulic power unit.

Power system management: The control PCB of the ship’s main engine, auxiliary engine and thruster needs to process complex signals such as fuel supply and exhaust regulation. For example, the power system PCB achieves high-density wiring through a multi-layer board design (such as 14 layers), shortens the signal transmission path, and reduces the failure rate.

Communication and safety systems: PCBs for satellite communications, radars, and AIS systems need to support high-frequency signal transmission and anti-interference design. For example, the fire alarm PCB of the ship safety system needs to integrate the smoke sensor signal processing circuit and trigger the ship-wide alarm through the relay unit.

Comfort system: PCBs for air conditioning, lighting, and entertainment systems need to meet the requirements of low power consumption and high stability. For example, the cruise entertainment system PCB adopts a flexible circuit board (FPC) design to adapt to the complex space layout in the cabin.

Development trend of ship printed circuit boards

Intelligence and Internet of Things integration: In the future, PCBs will support Internet of Things (IoT) technology to achieve remote monitoring and fault prediction of ship equipment. For example, by integrating sensors and edge computing chips, PCBs can analyze power system operation data in real time and optimize fuel efficiency..jpg)

Environmental protection and energy efficiency improvement: Low-power PCB design (such as using carbon film printed boards to reduce energy consumption) and environmentally friendly materials (such as lead-free processes) will become mainstream. For example, in green ship technology, PCBs need to be compatible with the control requirements of solar cell hybrid systems and dual-fuel engines.

High density and miniaturization: With the improvement of the integration of ship electronic equipment, PCB will develop in the direction of high-density interconnection (HDI) and system-level packaging (SiP). For example, rigid-flex PCB is used to achieve complex 3D wiring and reduce the size of the equipment.

Adaptability to extreme environments: For polar navigation or deep-sea exploration, PCB needs to have stronger resistance to low temperature and high pressure. For example, metal core printed circuit boards (such as aluminum substrates) are used to improve heat dissipation and adapt to the needs of high-power equipment.

Challenges and countermeasures for ship PCBs

Environmental adaptability challenges: Strengthen the three-proof coating and sealing design, and use corrosion-resistant materials (such as stainless steel substrates).

Long-term reliability challenges: Implement accelerated life testing (HALT) and high and low temperature cycle testing to verify the long-term stability of PCBs..jpg)

Technology iteration challenges: Establish an industry-university-research cooperation mechanism to promote the standardization and industrialization of ship PCB technology.

Summary

Ship printed circuit boards are the “nerve center” of ship electrical systems, and their technological development is directly related to the safety, reliability and intelligence level of ships. In the future, with the rapid development of the marine economy and the continuous advancement of ship technology, ship PCB will evolve towards higher integration, stronger environmental adaptability, and more intelligent direction. The industry needs to strengthen technological innovation and standard setting to promote the high-quality development of the ship PCB industry.

All products on this website are special products, and the market prices have been fluctuating.

Specific reference shall be made to the customer service quotation, because the product is a new product and the price is not real.

Please confirm the model and product, price and other detailed information with the customer service before placing an order. The website has been used.

New ones are on sale, please contact customer service for communication.

Related product recommendations:

BOSCH AMPLIFIER CARD 0811-405-011

BERG PROPULSION EK804 REV.1

BERG PROPULSION EK803 REV.2

BEPE ELEKTRONIK ROF 157-9028 REV.A ETCB-9816

BENTEC SYSTEMS A139-SCHL 240697L1

BENTEC SYSTEMS A135-SCHL0607971

BENTEC SYSTEMS A131-SCHL-310497L1

BEMAC UZUSHIO V07G3-BD-AC-P-NO-1479B

BEMAC UZUSHIO UAT-T-120-01J-NO-1110

BEMAC UZUSHIO UAT-SR-10-01J2-NO-1121

More…

Reviews

There are no reviews yet.