Core Function

The S-073N 3BHB009884R0021 is the core phase control module for the ABB ACS6000 medium-voltage inverter. Its main functions include:

Precise Phase Adjustment: By monitoring the phase data of the motor input voltage/current in real time (sampling frequency ≥ 10kHz, error < 0.1 degrees), it dynamically adjusts the phase to match the load demand, improving motor efficiency and power factor. This ensures the motor operates at the optimal phase, improving efficiency and power factor.

Multi-Mode Control: Supports V/F control, vector control, and direct torque control (DTC), adapting to various industrial scenarios (e.g., common DC bus architectures) such as fans, pumps, rolling mills, and hoists.

System Coordination: In multi-motor drive systems, phase synchronization is achieved through a common DC bus, avoiding harmonic interference and motor vibration, ensuring stable coordinated operation of multiple motors.

Dynamic Adaptability: During sudden load changes (such as rolling mill startup or fan acceleration), a dynamic phase compensation algorithm quickly responds to suppress current surges and voltage fluctuations, ensuring system stability.

Protection and Diagnostics: Integrated protection functions for overcurrent, overvoltage, undervoltage, and overtemperature, along with self-diagnosis and remote alarms, reduce the risk of downtime.

Technical Advantages

High Precision and Response Speed: Utilizing a PowerPC 405 microprocessor (500MHz-1.2GHz) and 256MB of SDRAM memory, it achieves millisecond-level torque response and phase adjustment, meeting the demands of highly dynamic loads.

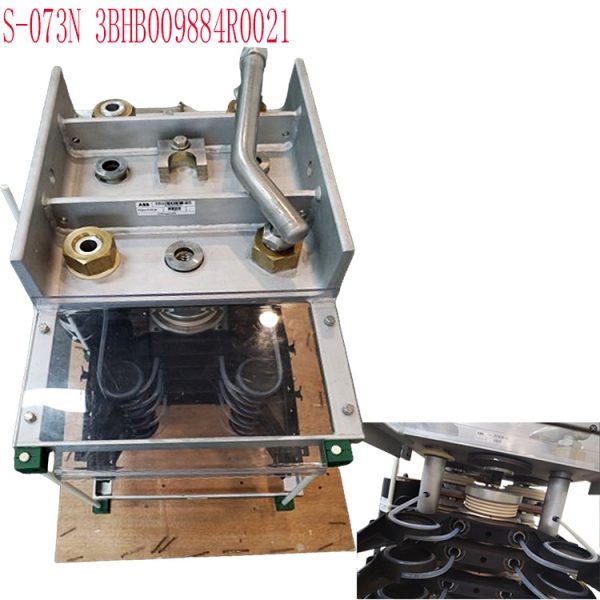

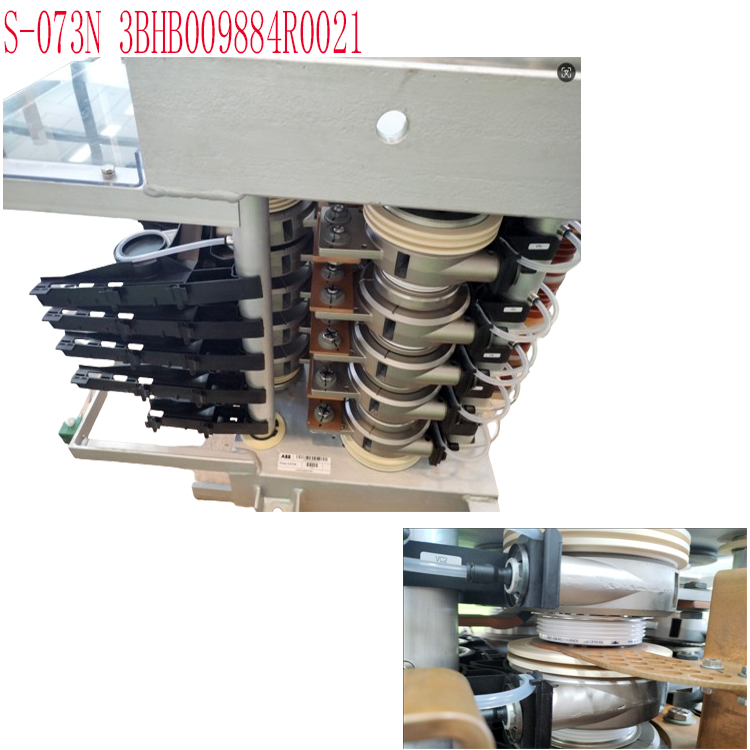

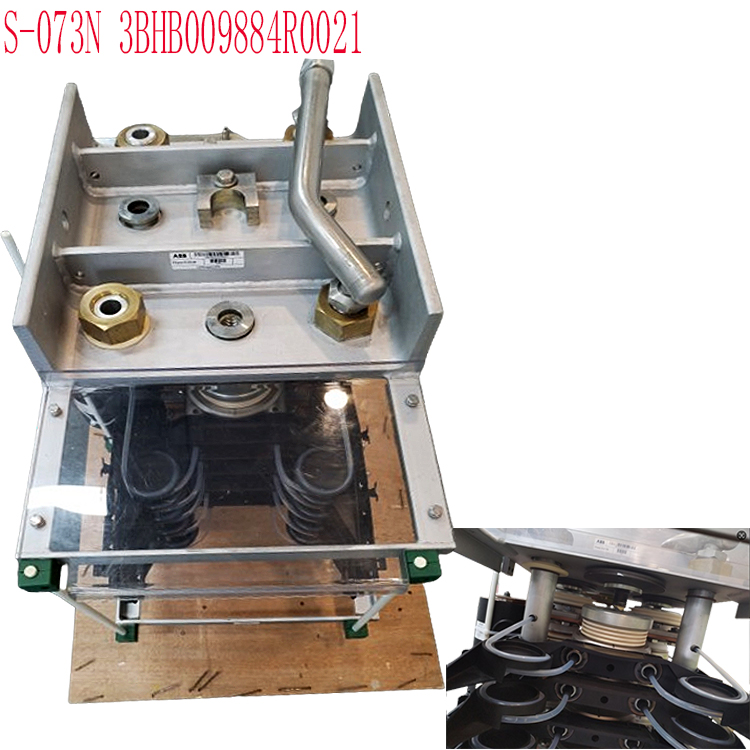

Modular Design: Hot-swappable and compact (approximately 4 × 25.3 × 27.3 cm) for easy installation and maintenance. Redundant configuration enables seamless switching between active and standby modules, ensuring continuous system operation.

The modular design supports hot-swappable operation, reducing maintenance time to 20 minutes. Triple redundant sensors and fault isolation ensure system operation even if a component fails.

Wide Environmental Adaptability: Operating temperature ranges from -25°C to +70°C, with an IP20 protection rating, it withstands harsh industrial environments such as humidity, vibration, and corrosive gases.

High efficiency and low losses: Based on IGCT (Integrated Gate-Commutated Thyristor) technology, the system reduces the number of power devices by 30%, lowering conduction and switching losses and improving overall system efficiency.

Communication compatibility: Supporting industrial protocols such as Modbus TCP/IP, PROFIBUS DP, and Ethernet/IP, it seamlessly integrates into ABB 800xA and AC 800M control systems, and can also interconnect with third-party devices such as Siemens and Omron.

A reserved VME bus interface (such as the SM128V card) supports direct connection to data acquisition systems such as ibaPDA, enabling 128 channels of analog/digital signal transmission.

Communication connection methods with the ACS6000 power supply system

Hardware connection

Connect to a master control unit (such as the AC 800M controller) or a host computer via standard communication interfaces (such as Ethernet, RS485, and CAN bus).

A common DC bus connects multiple motor drive units, enabling energy sharing and phase synchronization.

Physical Interface: Use standard industrial interfaces (such as RS485, CAN bus, and Ethernet) that match the system bus topology (such as a VME backplane).

Signal Mapping: Use a subroutine (such as the “IBA_SM128V” parameter block in LogiCAD) to map motor status signals to module memory addresses, enabling bidirectional data transmission.

Protocol Configuration

IP and Network Settings: Configure the module’s IP address, subnet mask, and gateway in engineering software (such as ABB Control Builder) to ensure interoperability with the master control system network.

Protocol Parameters: Select a communication protocol (such as Modbus TCP/IP), set the baud rate, data bits, stop bits, and parity, and match the master station configuration.

Port Mapping: Define input/output signal channels and map them to motor control parameters (such as speed and torque) or fault diagnostic signals.

Software Debugging and Integration

Parameter Settings: Use ABB Automation Builder software to perform motor identification, control mode selection (such as DTC), and protection threshold settings.

Test Verification: Simulate sudden load changes to verify phase adjustment speed and system stability; check communication latency and data transmission accuracy.

Fault Diagnosis: Use LED indicators (such as RUN/ERR) and self-diagnostic functions to quickly locate communication faults or module anomalies, and collaborate with ABB’s global technical support for maintenance.

System Integration Steps:

Single-Module Connection: Directly plugs into an ACS6000 rack slot and communicates with a master control unit (such as the PM861) via the backplane bus.

Multi-Module Collaboration: Within a common DC bus architecture, the VME bus enables data sharing and energy sharing (such as regenerating braking energy into the grid) between multiple modules.

Remote Monitoring: Connect to the Industrial IoT platform via the Ethernet interface for remote parameter adjustment and status monitoring.

Expansion and Compatibility: Supports integration with third-party devices (such as PLCs and sensors) via OPC UA or Industrial Ethernet protocols for data sharing and remote monitoring.

Expandable Input/Output modules (such as digital I/O and analog I/O) adapt to the signal acquisition and control needs of different industrial scenarios.

Summary: The S-073N module, through precise phase control and efficient communication integration, is a key component in the ACS6000 system, ensuring efficient and stable motor operation. Its modular design, wide environmental adaptability, and multi-protocol compatibility enable it to excel in heavy-duty industrial scenarios such as metallurgy, mining, chemicals, and power generation. It also supports flexible system expansion and remote maintenance, ensuring long-term reliable operation.

Related product recommendations:

ABB S-093H 3BHB030478R0309

ABB S-093S 3BHB030475R0009

S-093S 3BHB030475R0009

S-073N 3BHB009884R5211

S-073N 3BHB009884R0021 35SHY3545L0014

S-053M 3BHB012897R0003

S-073N 3BHB009884R0021 35SHY3545L0014

S-073N ABB 3BHB009884R0021

S-097H 3BHB009885R0052

S-093H 3BHB030478R0309

ABB 5SHY3545L0014 3BHB020720R0002

ABB 5SHY4045L0003

5SHY4045L0003 3BHE019719R0101

5SHY4045L0003 3BHB021400 3BHE019719R0101

5SHY3545L0005 336A4954ARP2

KUC321AE HIEE300698R1

KUC711AE 3BHB004661R0001

KUC720AE 3BHB000652R0001

GFD233A101 3BHE022294R0101

GFD563A102 3BHE046836R0102

GF D563 3BHE046836R010

3BHE017628R0002 PPD115A02

PPD517A3011 3BHE041576R3011

PCD232A 3BHE022293R0101

PCD237A101 3BHE028915R0101

PCD230A 3BHE022291R0101

PCD231B 3HHE025541R0101

PCD235C101 3BHE057901R0101

More……

Thank you for covering this so thoroughly. It helped me a lot.

Thanks for making this easy to understand even without a background in it.

Keep writing! Your content is always so helpful.

I love the clarity in your writing.

Your tips are practical and easy to apply. Thanks a lot!

I’ve bookmarked this post for future reference. Thanks again!

I love how clearly you explained everything. Thanks for this.

I really appreciate content like this—it’s clear, informative, and actually helpful. Definitely worth reading!

I love how clearly you explained everything. Thanks for this.

Thank you for putting this in a way that anyone can understand.

You’ve built a lot of trust through your consistency.

You have a real gift for explaining things.

This was incredibly useful and well written.

Great points, well supported by facts and logic.

I’ll definitely come back and read more of your content.

Excellent work! Looking forward to future posts.

Thank you for sharing this! I really enjoyed reading your perspective.

Your writing always inspires me to learn more.

It’s refreshing to find something that feels honest and genuinely useful. Thanks for sharing your knowledge in such a clear way.

Posts like this are why I keep coming back. It’s rare to find content that’s simple, practical, and not full of fluff.

This was incredibly useful and well written.

What I really liked is how easy this was to follow. Even for someone who’s not super tech-savvy, it made perfect sense.

I’ll definitely come back and read more of your content.

Thank you for making this topic less intimidating.

I appreciate the real-life examples you added. They made it relatable.

I enjoyed your perspective on this topic. Looking forward to more content.

Thanks for addressing this topic—it’s so important.

What an engaging read! You kept me hooked from start to finish.

I appreciate the depth and clarity of this post.

This was incredibly useful and well written.

Keep educating and inspiring others with posts like this.

This was a great reminder for me. Thanks for posting.

This gave me a whole new perspective on something I thought I already understood. Great explanation and flow!

I’ve bookmarked this post for future reference. Thanks again!

Very relevant and timely content. Appreciate you sharing this.

I’ll definitely come back and read more of your content.

You made some excellent points here. Well done!

You’re doing a fantastic job with this blog.

I love how practical and realistic your tips are.

This is one of the best explanations I’ve read on this topic.

This was a very informative post. I appreciate the time you took to write it.

I’ve bookmarked this post for future reference. Thanks again!

Your tips are practical and easy to apply. Thanks a lot!

Your articles always leave me thinking.

You’ve sparked my interest in this topic.

What I really liked is how easy this was to follow. Even for someone who’s not super tech-savvy, it made perfect sense.

I’ve bookmarked this post for future reference. Thanks again!

Keep writing! Your content is always so helpful.

You write with so much clarity and confidence. Impressive!

Such a simple yet powerful message. Thanks for this.

Great article! I’ll definitely come back for more posts like this.

I hadn’t considered this angle before. It’s refreshing!

This was so insightful. I took notes while reading!

I hadn’t considered this angle before. It’s refreshing!

This article came at the perfect time for me.

This content is gold. Thank you so much!

I’m definitely going to apply what I’ve learned here.

I’m definitely going to apply what I’ve learned here.

I love how clearly you explained everything. Thanks for this.

So simple, yet so impactful. Well written!

I love how practical and realistic your tips are.

This post cleared up so many questions for me.

Thank you for offering such practical guidance.

This was incredibly useful and well written.

I appreciate how genuine your writing feels. Thanks for sharing.

This article came at the perfect time for me.

I’ll definitely come back and read more of your content.

This was incredibly useful and well written.

This was really well done. I can tell a lot of thought went into making it clear and user-friendly. Keep up the good work!

This was easy to follow, even for someone new like me.

Thank you for being a bright light in sometimes dark times

Your content consistently brings joy and value to my day 💖

This is exactly type of positivity we need more

Love how you make everyone feel welcome in this space

Your posts always remind me why I love being part of this community 🚀

Your content never disappoints. Keep up the great work!

I like how you presented both sides of the argument fairly.

Hello my loved one! I want to say that this article is amazing, nice written and come with almost all significant infos. I would like to look more posts like this .

Backlinks in the discussion of what backlinks are is an example of contextual backlinks. This includes the most common ways for search engine optimization.