Description

Many products are not yet available. Please contact us for more information.

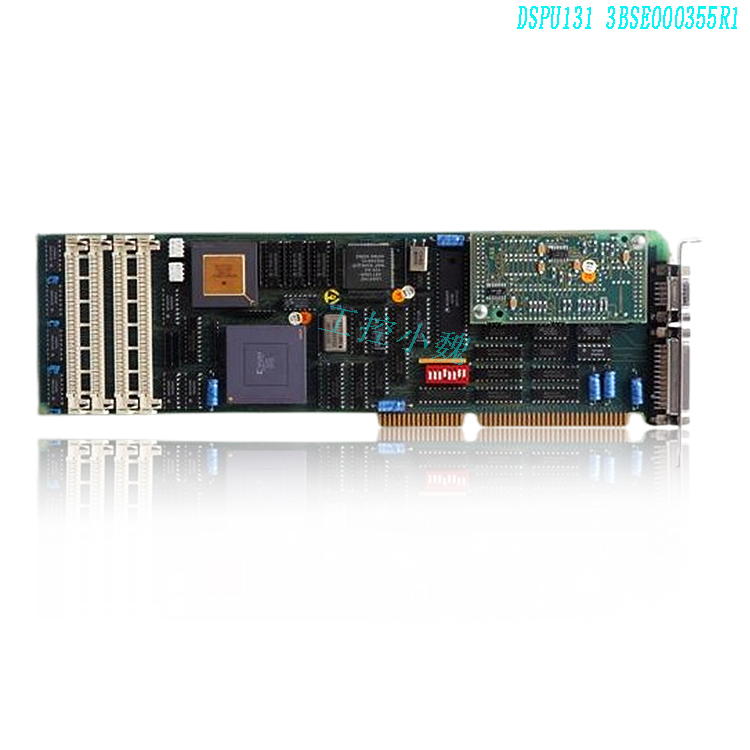

If the product model number differs from the displayed image, the model number will prevail. Please contact us for specific product images, and we will arrange to take photos in the warehouse for verification.

We have 76 shared warehouses worldwide, so it may sometimes take several hours for us to accurately return your product. Please understand. We will, of course, respond to your inquiries as soon as possible.

GVT8703200R0002 Other Names:

Controller Module GVT8703200R0002

GVT8703200R0002 Digital Module

I/O Module GVT8703200R0002

Main Series and Functions

Profibus Series: Such as the CI851K01 (AC800M Controller Expansion Module) and the CM572 (supporting the DP protocol for production line/robot control), can function as a master/slave, and are compatible with a 1.5Mbps baud rate. The PLC address and GSD file must match.

Modbus modules, such as the RPBA-01 (supporting RTU/RS-485), are compatible with ACS550/ACS580 inverters and PLC systems, enabling device-level communication.

Ethernet/Profinet modules, such as the PDD500A101 (multi-interface design, supporting C/C++ programming) and the CI854K01 (supporting remote monitoring and SCADA integration), enable cross-device data exchange through IP address and subnet configuration.

Specialized interface modules, such as the CI867K01 (intelligent I/O module, supporting rail mounting and online hot swapping) and the UFC911B106 (covering multiple scenarios such as industrial automation, energy management, and transportation systems).

Technology Development Trends:

Modular and Redundant Design: For example, the System 800xA platform supports CPU redundancy, communication redundancy, and power supply redundancy, improving system reliability. The AC800F controller offers flexible expansion via fieldbuses such as FOUNDATION Fieldbus and PROFIBUS.

GPU Acceleration and Parallel Processing: Modules like the CI858-1 integrate GPU technology to improve graphics rendering and computing performance, making them suitable for complex scenarios such as machine learning and HPC..jpg)

Open Protocols and Cross-System Integration: Support for open protocols such as OPC UA and MQTT enables seamless integration with DCS, PLC, SCADA, and ERP systems, reducing overall plant operating costs.

Typical Model Parameter Examples

CI851K01: AC800M series, 3BSE018101R1, supports Profibus DP master and slave, is resistant to electromagnetic interference, and requires matching PLC addresses.

RPBA-01: Supports Modbus RTU, compatible with AC500/ACS550/ACS580 inverters, CE/UL certified, and has an RS-485 interface.

PDD500A101: 3BHE037649R0101, multiple communication interfaces (Ethernet/serial), a high-speed processor, and support for C/C++ programming, suitable for redundant systems.

CI867K01: 3BSE043660R1, intelligent I/O module, DIN-rail mounting, supports online replacement, and is compatible with SCADA systems.

RPBA-01: Designed specifically for ABB inverters (such as the ACS550/ACS580 series), supports the Modbus RTU protocol (RS-485 interface), is compatible with PLC systems, and is CE/UL certified. It is suitable for networked control of industrial equipment.

3BUS208796-501: Supports inter-PLC data exchange, SCADA system integration, and intelligent manufacturing scheduling, covering scenarios such as robot control, smart grids, renewable energy (solar/wind) monitoring, sewage treatment, and intelligent transportation (traffic light/camera linkage).

CI930F: Supports multiple protocols such as Modbus, Profibus, and EtherNet/IP. It features high-speed data transmission (real-time performance guaranteed), high reliability (industrial-grade environmental resistance design), and easy programming. It is suitable for process control, remote monitoring, and host computer integration.

DT602: Utilizes advanced communication technology for low-latency transmission, is compatible with multiple protocols (such as Ethernet/IP), and supports expansion interfaces (such as storage modules) for control system integration, remote monitoring, and data acquisition and analysis.

CI854K01: Focused on manufacturing, water treatment, and energy management, it enables coordinated control of sensors/actuators/PLCs/inverters through protocol compatibility, improving production efficiency and reducing maintenance costs.

ABB Communication Module GVT8703200R0002 Core Application Scenarios

Industrial Automation: Interconnection of production line equipment (such as PLCs, inverters, and robots), intelligent manufacturing scheduling, and real-time monitoring of process parameters.

Energy Management: Smart grid (substation/distribution network data exchange), renewable energy (photovoltaic/wind power equipment data acquisition), power flow optimization and load management.

Infrastructure: Intelligent transportation (traffic signal/sensor data communication), coordinated control of railway/subway systems, and environmental monitoring (real-time air quality and noise acquisition).

Process Control: Chemical Industry, Water Treatment (water quality/flow/chemical composition monitoring), Building Automation (building equipment linkage).

Manufacturing: Production Line Equipment Interconnection, Robot Control (e.g., ABB robots interoperating with PLCs via Profinet), Quality Inspection Data Collection.

Transportation and Infrastructure: Intelligent Traffic Signal Control, Metro/Railway Equipment Interoperability, Logistics and Warehousing Automation (e.g., AGV Scheduling).

Environment and Architecture: Wastewater Treatment Water Quality Monitoring, Real-Time Air Quality/Noise Monitoring, Building Automation (Lighting/HVAC/Security System Integration).

Special Applications: Data Center Server-to-Server Communication, Petrochemical Process Control, Medical Equipment Data Transmission.

ABB Communication Module GVT8703200R0002 Core Features

Data Transmission and Integration: Enables real-time data exchange between PLCs, inverters, sensors, and actuators, supporting protocols such as Profibus, Profinet, and Modbus to ensure device interoperability.

Remote Monitoring and Control: Data is transmitted to a SCADA system or cloud platform via Ethernet/4G/5G networks, enabling remote status monitoring, program loading, and fault diagnosis (e.g., ABB robots support TCP/IP communication with socket programming and database connectivity).

System Expansion and Redundancy: The modular design supports I/O expansion and redundant configurations (e.g., hot standby), improving system reliability. Some models support online module replacement, reducing downtime..jpg)

Anti-Interference and Industrial-Grade Design: Utilizes industrial-grade hardware (e.g., vibration resistance and electromagnetic shielding) to withstand harsh environments. Features self-diagnostics for real-time module status monitoring and alarm generation.

ABB Communication Module GVT8703200R0002 Technical Features and Advantages

Protocol Compatibility: Supports multiple interfaces, including Modbus, Profibus, EtherNet/IP, Ethernet, serial (RS-485), and wireless communication, ensuring cross-brand device connectivity.

Reliability and Stability: The industrial-grade design (high-temperature resistance, dustproof, and electromagnetic interference resistance) has been rigorously tested to ensure long-term, trouble-free operation.

Ease of Use: Programming tools and configuration documentation are provided, supporting multiple development environments and lowering the deployment barrier.

Scalability: The modular design supports interface expansion (such as additional communication modules and storage units) to meet customized needs.

Summary: With multi-protocol support, high reliability, and flexible scalability, ABB communication modules have become core communication hubs in fields such as industrial automation, energy management, and transportation systems.

ABB Communication Module GVT8703200R0002 Configuration and Commissioning Methods

Hardware Connection: Install the communication module in the control cabinet (such as the DSQC 377B for Profibus), connect the twisted pair cable/fiber optic cable, and ensure matching terminal resistors (Profibus requires 120Ω at both ends).

ABB Communication Module GVT8703200R0002 Parameter Configuration:

Robot/PLC Settings: Configure the network name, station address, IP address, subnet mask, and I/O signal mapping (such as defining digital input/output address areas) in the teach pendant/PLC software.

Protocol Compatibility: For Profibus, set the SYNC/FREEZE mode; for Profinet, configure the device name and real-time communication parameters (RT/IRT).

Testing and Troubleshooting: Monitor I/O status using the teach pendant and send test signals from the PLC. If communication is interrupted, check for address conflicts, protocol compatibility, and electromagnetic interference. Replace the module or add shielding measures if necessary.

All products on this website are special products, and market prices fluctuate.

Please refer to customer service for specific quotes. Since these products are new, prices are not official.

Please confirm model, product, price, and other details with customer service before placing an order. This website is used.

New products are available for sale. Please contact customer service for details.

Related product recommendations:

S-093H 3BHB030478R0009

S-093M 3BHB009885R0013

S-093R 3BHB009885R5311

S-097H 3BHB009885R0052

S-093M 3BHB009885R0063

ABB S-093H 3BHB030478R0309

ABB S-093S 3BHB030475R0009

S-093S 3BHB030475R0009

S-073N 3BHB009884R5211

S-073N 3BHB009884R0021 35SHY3545L0014

S-053M 3BHB012897R0003

S-073N 3BHB009884R0021 35SHY3545L0014

S-073N ABB 3BHB009884R0021

S-097H 3BHB009885R0052

S-093H 3BHB030478R0309

More……

-300x300.jpg)

Reviews

There are no reviews yet.