I. Core Functions

High-Precision Phase Control and Power Quality Optimization

As a dedicated phase control module in the ABB ACS6000 medium-voltage inverter (a core component of the PCS6000 system), it achieves a phase control accuracy of ±0.1°, ensuring the synchronization of multi-phase power output, reducing harmonic distortion, and improving power quality.

Supports current regulation for power levels of 3–27 MW, adaptable to 6.0–6.9 kV AC medium-high voltage systems, meeting the needs of high-power industrial scenarios such as metallurgy, mining, chemical, power, and wind power.

Multi-Phase Power Balancing and Dynamic Adjustment

In three-phase or multi-phase power systems, it automatically monitors the phase difference of current and voltage in each phase, allocating power ratios through internal algorithms to avoid single-phase overload and improve system stability and efficiency.

In conjunction with Direct Torque Control (DTC) technology, it dynamically matches load demands, for example, increasing the phase angle to increase torque when the motor load increases and decreasing the phase angle when the load decreases, achieving precise matching of “load-phase-torque”.

Protection and Fault Isolation

Integrates overvoltage (OVP, threshold 110% of rated voltage), overcurrent (OCP, threshold 150% of rated current), and overheat (OTP, operating temperature +90℃) protection with a response time of <1ms, enabling rapid response to abnormal operating conditions.

Supports fault code uploading (e.g., “E01 Overvoltage”, “E02 Overcurrent”), facilitating rapid problem location by maintenance personnel.

Communication and System Integration

Supports industrial protocols such as Modbus RTU/TCP, Profinet RT, and Ethernet/IP, seamlessly integrating with PCS6000 control cabinets (e.g., GBU72 circuit breaker control units), HMIs, and external PLC/DCS systems for data exchange and remote monitoring.

High-speed communication with the IGCT drive unit via fiber optic interface, offering strong resistance to electromagnetic interference.

Phase Synchronization and Control

This module is a core component of the ABB PCS6000 medium-voltage inverter/power system, responsible for precisely regulating the phase synchronization of voltage and current to ensure stable system operation under complex conditions such as grid fluctuations and load abrupt changes. For example, in grid-connected operation, it achieves synchronous parallel connection of generator sets by adjusting the phase in real time, avoiding system failures caused by phase differences.

Power Quality Management

Supports harmonic analysis, dynamic voltage control, reactive power compensation, and fault ride-through (FRT) functions. In new energy scenarios such as wind power generation, as a core module of STATCOM (Static Synchronous Compensator), it improves power quality and meets grid specifications.

System Protection and Reliability

Built-in overvoltage, overcurrent, short-circuit, and over-temperature protection mechanisms, combined with a modular design supporting hot-swapping for easy and rapid maintenance. High power density and low loss are achieved through IGCT (Integrated Gate Commutated Thyristor) technology, ensuring system reliability in harsh industrial environments (such as oil and gas, metallurgy, and mining).

Four-Quadrant Operation and Energy Recovery

Supports bidirectional power flow, enabling regenerative braking (e.g., elevator group control systems), reducing energy consumption and improving system efficiency.

II. Working Principle

Technical Basis: IGCT and Power Electronic Conversion

Utilizing IGCT technology, combined with the low conduction loss of thyristors and the fast turn-off characteristics of transistors, it achieves efficient DC-AC/AC-DC conversion. The module uses a three-phase inverter bridge topology to achieve high-precision phase control in high-voltage, high-current scenarios (e.g., 4-120 MVA power range).

Phase Detection and Synchronization

The module incorporates a phase-locked loop (PLL) and a high-precision ADC (1 MHz sampling rate) to collect grid voltage and current signals in real time and compare them with a preset phase reference value. If the deviation exceeds ±0.5°, an adjustment signal is immediately output to ensure phase synchronization.

A trigger signal is sent to the IGCT via an ST-type fiber optic interface to precisely control its on/off timing, adjust the output voltage phase angle, and achieve dynamic matching between the load and phase.

Phase Detection and Adjustment

Built-in high-precision phase detection circuitry to acquire voltage/current signals in real time and dynamically adjust the output phase through control algorithms (such as ABB Direct Torque Control, DTC). For example, in motor control, it ensures phase consistency during synchronous operation of multiple motors, avoiding vibration and efficiency loss.

Multiphase System Power Balance

Real-time monitoring of three-phase current and voltage phase differences, automatically adjusting the power output of each phase through internal algorithms. For example, if a phase load is too high, the phase output of that phase is reduced, while the power of other phases is increased, preventing single-phase overload.

Modular Design and Communication Integration

Modular architecture supports flexible configuration and can work collaboratively with other components (such as control units and drives). Supports multiple communication protocols (such as Ethernet/IP, Modbus TCP/IP), achieving seamless integration with SCADA systems and PLCs to meet industrial automation needs.

Dynamic Control and Protection Mechanisms

Based on real-time feedback closed-loop control, it quickly responds to load changes (such as motor starting impact and grid frequency fluctuations). Built-in redundant cooling systems (air-cooled/water-cooled) and fault isolation functions ensure continuous system operation. For example, in wind farms, STATCOM enables dynamic reactive power compensation to maintain grid voltage stability.

Protection Mechanism

When overvoltage, overcurrent, or overheating is detected, two levels of protection are triggered:

Level 1 Protection: Phase regulation is suspended, and a fault signal is sent to the PCS6000 main controller;

Level 2 Protection: If the fault is not cleared, the IGCT trigger signal is cut off, power output is forcibly stopped, and a fault code is uploaded via the communication interface.

High-Efficiency and Heat Dissipation Design

Utilizing IGCT (Integrated Gate Commutated Thyristor) technology, conduction losses are ≤2.0 V, switching frequency is 2–5 kHz (adjustable), and typical efficiency is ≥98%. The high-frequency switching design reduces motor operating noise and improves energy conversion efficiency.

Module dimensions are 220 mm × 180 mm × 45 mm. The aluminum housing balances heat dissipation and mechanical strength, supporting forced air cooling or liquid cooling. Liquid cooling improves heat dissipation efficiency by 40%.

Environmental Adaptability

Operating temperature range: -40℃ to +85℃; Protection rating: IP20 (body); IP54 (dustproof and waterproof) when used with a PCS6000 cabinet. ESD protection: ±8 kV (contact discharge), ±15 kV (air discharge), suitable for strong electromagnetic environments in industrial settings.

III. Specific Application Scenarios in the PCS6000 System

Industrial Drive: In scenarios such as rolling mills, continuous casting machines, mine hoists, and belt conveyors, precise phase control enables synchronized equipment operation, improving processing accuracy and safety.

Power Auxiliary: Used in conjunction with STATCOM (Static Synchronous Compensator) to improve the grid power factor (to above 0.98), or to achieve phase synchronization of AC/DC conversion in HVDC converter stations.

Renewable Energy Grid Connection: In megawatt-level converters of wind and photovoltaic power plants, adjusting the output power phase to synchronize with the grid reduces curtailment rates and improves grid connection stability.

Infrastructure: Supports high-power motor drive and power quality optimization in scenarios such as subways and airports.

Summary: The ABB S-093H 3BHB030478R0009 phase control module plays a core role in the PCS6000 system through high-precision phase synchronization, IGCT technology, modular design, and multiple protection mechanisms, ensuring the efficient, stable, and reliable operation of the power system, especially excelling in high-voltage, high-power scenarios.

Related product recommendations:

S-093H 3BHB030478R0009

S-093M 3BHB009885R0013

S-093R 3BHB009885R5311

S-097H 3BHB009885R0052

S-093M 3BHB009885R0063

ABB S-093H 3BHB030478R0309

ABB S-093S 3BHB030475R0009

S-093S 3BHB030475R0009

S-073N 3BHB009884R5211

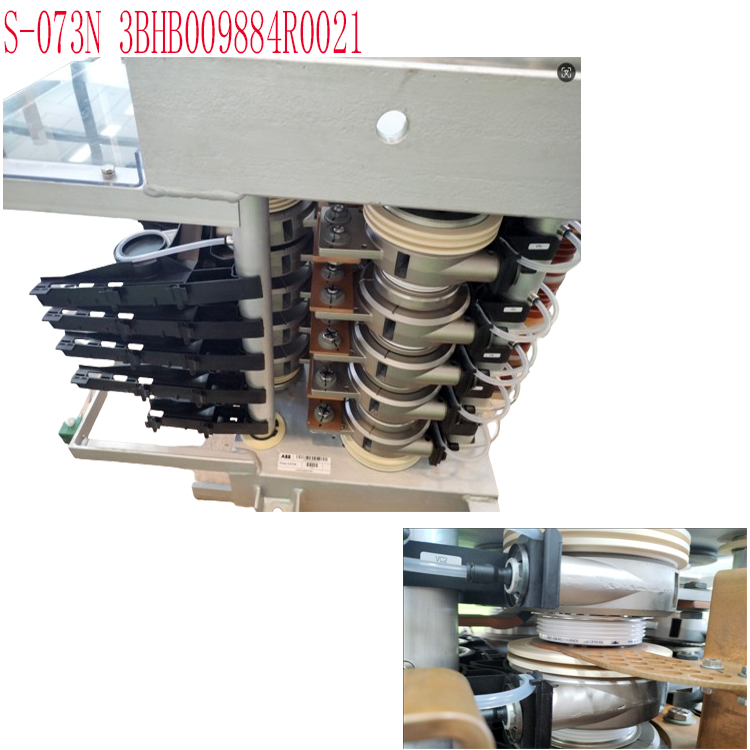

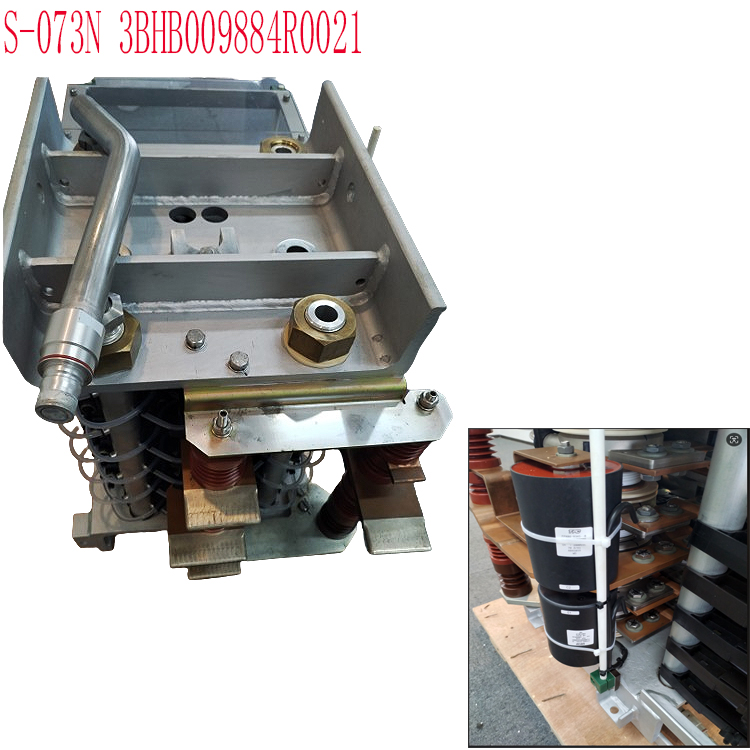

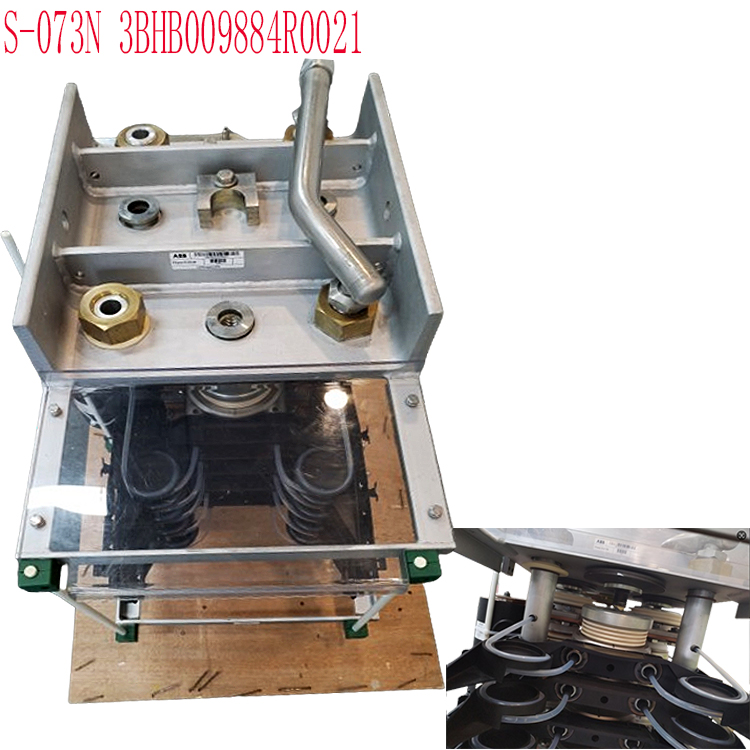

S-073N 3BHB009884R0021 35SHY3545L0014

S-053M 3BHB012897R0003

S-073N 3BHB009884R0021 35SHY3545L0014

S-073N ABB 3BHB009884R0021

S-097H 3BHB009885R0052

S-093H 3BHB030478R0309

More……