Description

Many products are not yet on the shelves, please contact us for more products

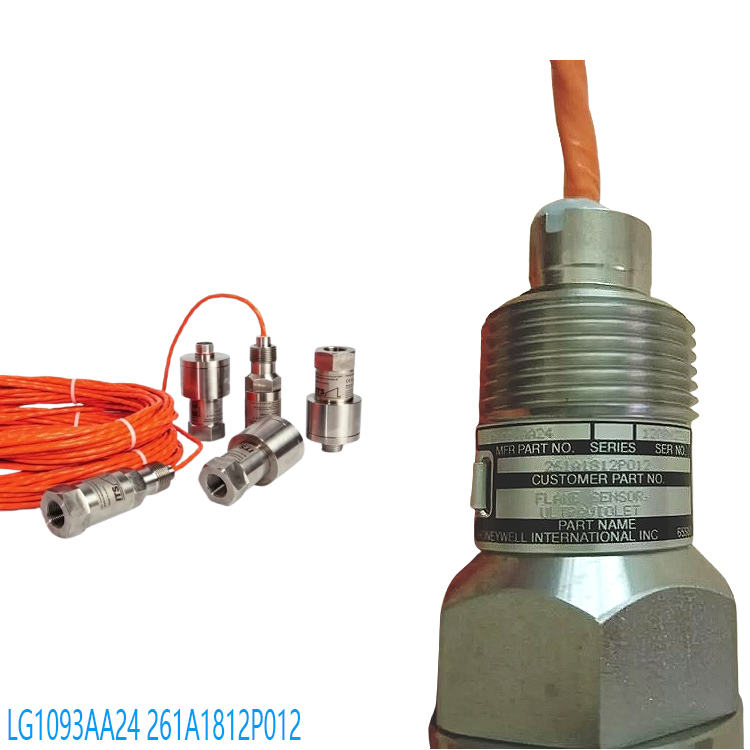

If the product model is inconsistent with the display picture, the model shall prevail. Please contact us for specific product pictures, and we will arrange to take photos in the warehouse for confirmation

We have 76 shared warehouses around the world, so sometimes it may take several hours to return to you accurately, please understand. Of course, we will respond to your concerns as soon as possible.

362A1052P104 other names:

Flame sensor 362A1052P104

362A1052P104 ultraviolet flame sensor

Gas turbine ultraviolet detector 362A1052P104

362A1052P104 is a UV-based flame detector that can quickly and accurately detect fire sources. It uses advanced signal processing technology and automatic calibration functions to provide reliable protection for fire safety. The detector is widely used in many fields such as oil, natural gas, electricity, chemicals, aerospace, manufacturing, construction, and oil platforms, and is of great significance for early detection of fire risks and prevention of accidents.

Working principle

The working principle of ultraviolet flame detectors is based on ultraviolet radiation generated when flames burn. The 362A1052P104 detector senses this radiation through an internal UV sensor. When it senses enough UV signals, the detector will send an alarm signal to notify the fire protection system or relevant personnel to handle it.

Product Features

High sensitivity and accuracy: The 362A1052P104 flame detector has high sensitivity and accuracy, and can quickly respond to the presence of flames, even when the flame is just formed.

Low false alarm rate: Since the detector only responds to UV radiation, it can reduce false alarms caused by other factors (such as light, smoke, etc.).

Advanced signal processing technology: The detector uses advanced signal processing technology to effectively filter out interference signals and improve the stability of the detector.

Automatic calibration function: The detector has an automatic calibration function, which can simplify maintenance work and reduce maintenance costs.

Application areas

362A1052P104 flame detectors are widely used in oil, natural gas, electricity, chemical industry, aerospace, manufacturing, construction and oil platforms. They are used to monitor flames in the environment, detect fire risks in time, prevent accidents, and provide strong protection for people’s lives and property safety.

Oil and gas industry: used to monitor flames in oil wells, natural gas equipment, petrochemical plants, etc., which helps to detect fire risks early and prevent accidents.

Power plants and energy facilities: In power plants and other energy production facilities, ultraviolet flame detectors can be used to monitor flames, ensure the normal operation of equipment and improve safety.

Chemical and pharmaceutical industries: used to monitor fire risks in chemical plants and pharmaceutical plants, detect and take measures to prevent accidents early.

Aerospace: In the engine systems of aviation and spacecraft, this type of flame detector can be used to monitor flames in the engine combustion chamber to ensure the normal operation of the engine.

Manufacturing: In various manufacturing environments, ultraviolet flame detectors can be used to monitor industrial furnaces, gas heating systems and other potential fire sources.

Buildings and commercial buildings: used in buildings, commercial buildings and large facilities to monitor fire risks and improve the safety of buildings and personnel.

Offshore and onshore oil platforms: On offshore and onshore oil drilling and production platforms, this type of flame detector can be used to monitor potential fire hazards.

All products on this website are special products, and the market price has been fluctuating.

The specific quotation is subject to the customer service. Because the product is a new product, the price is not real.

Please confirm the model and product, price and other detailed information with the customer service before placing an order. The website has been used.

New ones are on sale, please contact customer service for communication.

Model recommendation:

CC-PAOH01

CC-IP0101

CC-IP0101 51410056-175

CC-MCAR02

CC-PAIH01 51405038-175

CC-PAIH01

CC-PAIH02

CC-PAIH51 51410069-275

CC-PAIH51

CC-PAIM01 51405045-175

TC-PPD011

TC-ODK161

TC-FPCXX2

TC-CCR014

05701-A-0502

05701-A-0301

05701-A-0451

05701-A-0327

05701-A-0283

05701-A-301ISS

05701-A-0288

05701-A-0294

05704-A-0123

05704-A-0146

More……

admin –

I. Core Parameters and Performance

Working Principle: Utilizes ultraviolet (UV) sensing technology. It triggers an alarm by detecting UV radiation generated by flame combustion, offering fast response and a low false alarm rate (anti-interference design filters out non-flame light sources such as sunlight and electric arcs).

Technical Specifications:

Material: Aerospace-grade aluminum alloy with P104 ceramic coating, corrosion-resistant and high-temperature resistant (-40℃~+220℃).

Protection Rating: IP67 (waterproof and dustproof), suitable for harsh industrial environments.

Electrical Parameters: 24V DC/110V AC dual-mode power supply, compatible with various industrial power systems.

Dimensions and Weight: 90mm×52mm×34mm, 850g±2%, modular interface supports rapid integration.

Lifespan: Over 50,000 cycles under ISO 9001:2015 certification, failure rate <0.01%.

II. Key Functions and Advantages

Intelligent Compatibility: Optional IoT sensor, enabling real-time performance monitoring and data transmission via RS-FS-9001 protocol, supporting integration with DCS, PLC, and other control systems.

Automatic Calibration: Built-in automatic calibration function reduces manual maintenance costs and ensures long-term stable accuracy.

Anti-interference Design: Advanced signal processing technology filters out interference signals such as smoke and steam, reducing the risk of false alarms.

Modular Interface: Standardized 362A1052 interface, compatible with similar equipment from brands such as GE and Reuter-Stokes, adaptable to various industrial scenarios (e.g., gas turbines, boilers, oil platforms).

III. Installation and Maintenance Requirements

Installation Specifications:

Must be operated by qualified personnel, complying with local electrical and fire regulations.

The installation location must ensure the sensor is unobstructed, avoiding high temperature, high-pressure water splashes, and mechanical impact.

Requires integration with a control system (e.g., Honeywell Analytics platform), setting alarm thresholds and linkage logic.

Maintenance Points:

Regularly clean the sensor screen to prevent dust accumulation from affecting sensitivity. Unauthorized disassembly or alteration of the equipment is prohibited and may affect warranty and performance.

Warm-up time must follow the manual's requirements to ensure stable detector startup.

Damaged equipment must be repaired by contacting official after-sales service to avoid unauthorized repairs that could lead to malfunction.

IV. Application Scenarios and Industry Adaptability

Typical Fields: Oil and Gas, Power, Chemical, Aerospace, Manufacturing, Building Safety, and Offshore Drilling Platforms.

Example Scenarios:

Gas turbine combustion monitoring, boiler flame monitoring, and tank area fire prevention.

High-risk industrial environments (e.g., high temperature, high dust, flammable and explosive areas).

Requires integration with fire protection systems to achieve early fire warning and emergency response.

https://www.weikunfadacai1.com/product/362a1052p104-flame-detector-honeywell-362a1052p104/