Description

Many products are not yet listed. Please contact us for more information.

If the product model differs from the displayed image, the model number shall prevail. Please contact us for specific product images; we will arrange to take photos in our warehouse for confirmation.

We have 76 shared warehouses worldwide, so it may sometimes take several hours to accurately return the information to you. We apologize for any inconvenience. Of course, we will respond to your inquiries as soon as possible.

125680-01 3500/40M Other Names:

Four-Channel Monitor 125680-01 3500/40M

125680-01 3500/40M Monitoring Module

Proximity Seismic Monitor 125680-01 3500/40M

125680-01 3500/40M Proximity Sensor I/O Module

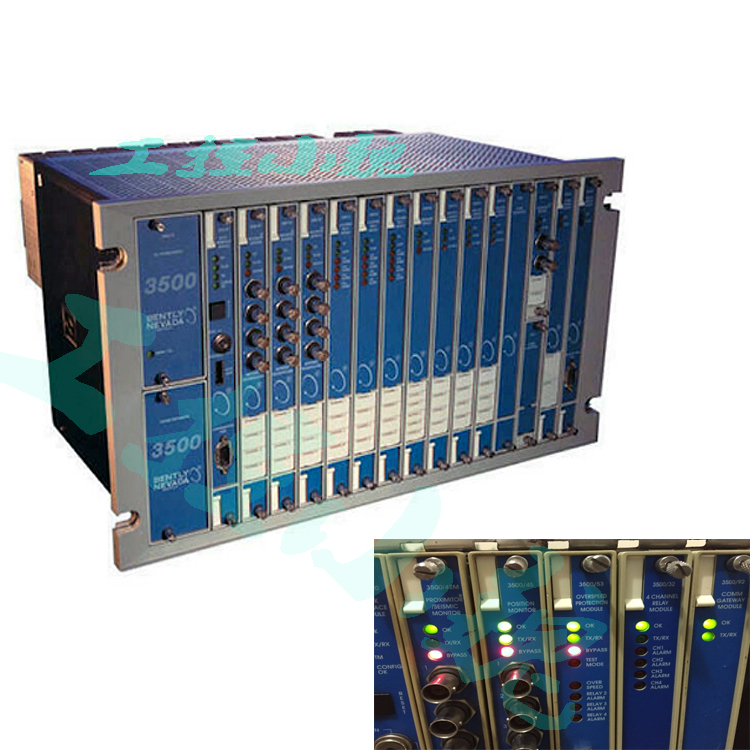

The Bently Nevada 3500/40M proximity monitor (model 3500/40M-01-00, part number 125680-01) is a core component of the 3500 series monitoring system, specifically designed for high-precision vibration and displacement monitoring of industrial rotating machinery.

Technical Parameters and Core Performance

Channel Configuration: 4 independent input channels, compatible with Bently Nevada proximity sensors (such as eddy current probes), supporting programmable functions for radial vibration, thrust position, differential expansion, eccentricity, and REBAM (radial bearing wear monitoring). Each channel can perform two measurement tasks simultaneously, and channels 1-2 and 3-4 can be independently configured with function combinations.-2.jpg)

Signal Processing: Built-in high-precision signal conditioning circuitry, supporting radial vibration frequency response of 0-10kHz (-3dB), displacement measurement accuracy of ±0.1mm, and thrust position resolution of 0.25μm. Output supports 4-20mA analog signals, relay alarms, and Keyphasor pulse signals.

Electrical Characteristics: Input impedance 10kΩ (standard I/O), effective impedance 50kΩ under TMR redundancy configuration; power consumption 7W; power supply requirement 24VDC, supporting redundant power supply (such as 3500/15 power supply module).

Sensitivity and Impedance:

Radial Vibration/Axial Displacement: 3.94 mV/μm (100 mV/mil) or 7.87 mV/μm (200 mV/mil);

Differential Expansion: 0.394 mV/μm (10 mV/mil) or 0.787 mV/μm (20 mV/mil);

Input Impedance: Standard I/O is 10kΩ, effective impedance increased to 50kΩ with TMR redundancy configuration.

Output Interface: Supports 4-20mA analog output, relay alarm output, and Keyphasor pulse output, compatible with DCS/PLC systems (such as Siemens, ABB) and System 1 condition monitoring software.

Functional Characteristics and Protection Mechanisms

Multi-mode Monitoring: Programmable via 3500 Rack Configuration software, enabling vibration (radial/axial), displacement (thrust/differential expansion), eccentricity, speed synchronous analysis (Keyphasor), and REBAM bearing wear monitoring.

Alarm and Protection: Users can customize static threshold values (such as vibration amplitude and displacement deviation), supporting both Alert and Danger dual-level alarms, triggering relay output or system shutdown.

Redundant Design: Supports triple module redundancy (TMR) configuration, avoiding single points of failure through a 3-out-of-2 voting mechanism, suitable for scenarios with high safety requirements (such as power and petrochemical industries).

Diagnosis and Maintenance: Front panel LED indicators (OK, TX/RX, Bypass) provide real-time feedback on operating status; supports historical trend analysis and proactive maintenance strategy deployment to reduce the risk of unplanned downtime.

Environmental Adaptability: Operating temperature range -40℃ to +85℃, IP67 protection rating, adaptable to industrial environments with vibration, dust, and corrosive gases.

Application Scenarios and Industry Coverage

Typical Applications: Monitoring parameters such as shaft vibration, bearing metal temperature, stator temperature, and casing expansion in rotating machinery such as steam turbines, generators, compressors, and pumps to prevent equipment failures caused by overheating, eccentricity, or abnormal vibration.

Industry Distribution:

Power: Generator and transformer bearing monitoring;

Oil & Gas: Centrifugal compressor and pump equipment status monitoring;

Chemical: Reactor and centrifugal separator vibration analysis;

Manufacturing: Machine tool, injection molding machine, and die-casting machine process optimization.

Supporting Systems and Expansion Components

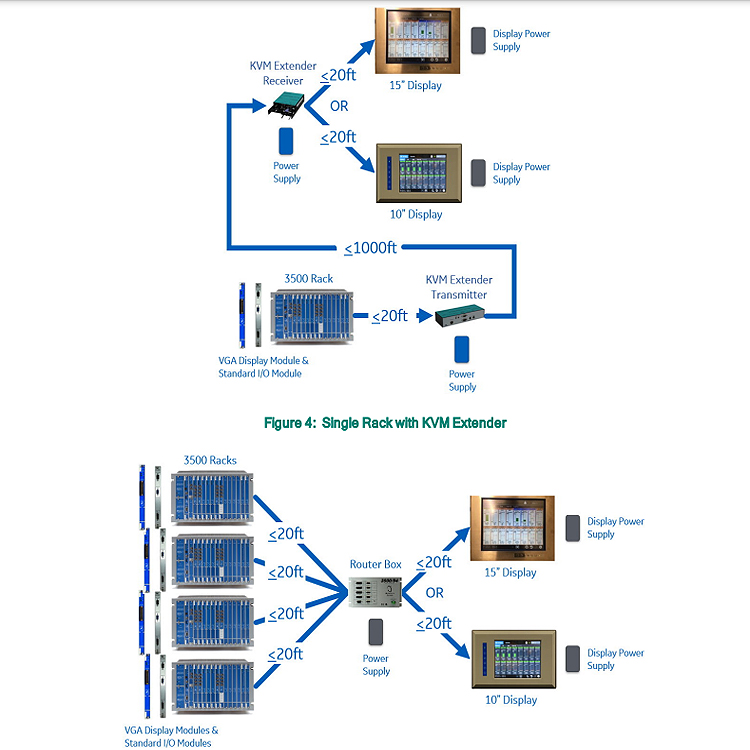

Frame and Power Supply: Requires the 3500/05 frame, 3500/15 redundant power supply module, and 3500/22 TDI communication module, supporting Modbus TCP/IP and RS-485 protocols.

Relays and Display Modules: Optional 3500/32 (4-channel), 3500/33 (16-channel), or 3500/34 TMR relay modules; the 3500/93/94/95 display module provides a localized operation interface and event log query.

Sensors and Accessories: Compatible with 3-wire/4-wire RTDs, thermocouples, and Bently eddy current sensors; external terminal blocks (e.g., 172115-01) simplify field wiring and support DIN rail mounting.

Software Tools: Monitor parameters (such as alarm thresholds and filter settings) are programmed via the 3500 frame configuration software; integrated System 1 software enables remote monitoring and data analysis.

Certifications and Standards

Complies with international standards such as API 670 (machine protection), API 618 (reciprocating compressors), DNV, ATEX, and CE, ensuring compliance and safety in harsh industrial environments.

In summary, the Bently Nevada 3500/40M 125680-01 proximity monitor, with its multi-channel, high-precision, redundant design and broad industry adaptability, has become a core device for vibration and displacement monitoring of industrial rotating machinery, effectively improving equipment reliability and extending service life.

Please note that all products on this website are specialty items, and market prices are constantly fluctuating.

Please refer to customer service for a specific quote, as the price may not be accurate for new products.

Please confirm the model, product, price, and other details with customer service before placing an order. This website is currently in use.

New items are available for sale; please contact customer service for further information.

Popular model recommendations:

BENTLY 3500/40M

BENTLY 3500/42M

BENTLY 3500/65

BENTLY 3500

BENTLY 3500/05-02-04-00-00-01

BENTLY 3500/05-01-02-00-00-01

BENTLY 133388-01 AT LOW

161204-01 3500/91

BENTLY NEVADA 3500

BENTLY 3500/15 127610–01

BENTLY 1900/65A-00–00–02–00–01

BENTLY 3500/40M

BENTLY ASSY78462-01U

BENTLY 3500/42M

BENTLY 3500/65

125720-01 BENTLY

More……

admin –

Signal Processing: Built-in high-precision signal conditioning circuitry, supporting radial vibration frequency response of 0-10kHz (-3dB), displacement measurement accuracy of ±0.1mm, and thrust position resolution of 0.25μm. Output supports 4-20mA analog signals, relay alarms, and Keyphasor pulse signals.

Electrical Characteristics: Input impedance 10kΩ (standard I/O), effective impedance 50kΩ under TMR redundancy configuration; power consumption 7W; power supply requirement 24VDC, supporting redundant power supply (such as 3500/15 power supply module).

https://www.weikunfadacai1.com/product/bently-3500-65/

https://www.weikunfadacai1.com/product/bently-125680-01/