Description

Many products are not yet listed. Please contact us for more information.

If the product model differs from the displayed image, the model number shall prevail. Please contact us for specific product images; we will arrange to take photos in our warehouse for confirmation.

We have 76 shared warehouses worldwide, so it may sometimes take several hours to accurately return the information to you. We apologize for any inconvenience. Of course, we will respond to your inquiries as soon as possible.

3500/65-01-00 145988-02 Other Names:

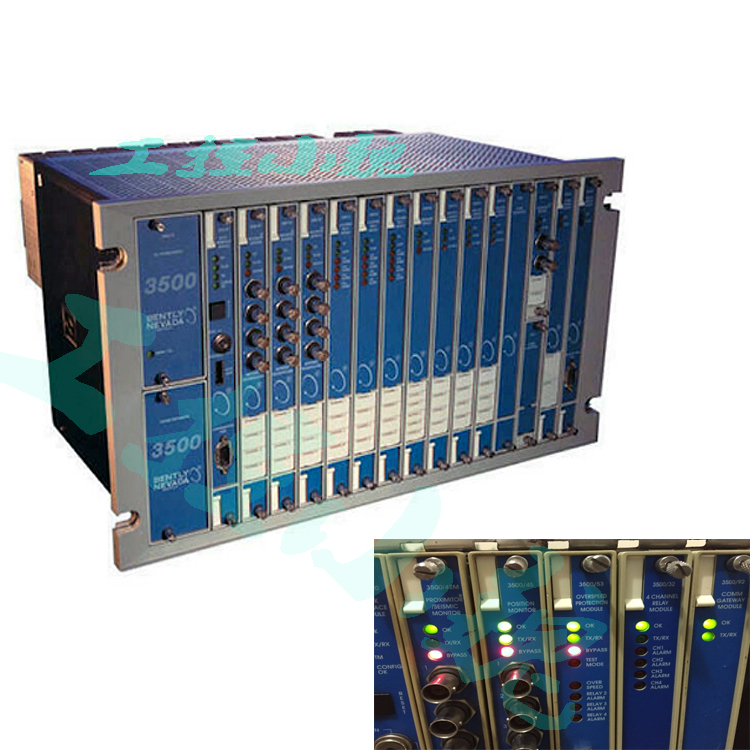

16-Channel Temperature Monitor 3500/65-01-00 145988-02

3500/65-01-00 145988-02 16-Channel Temperature Monitor

16-Channel Temperature Sensor 3500/65-01-00 145988-02

Technical Parameters and Functions

Channel Configuration: Supports 16 independent temperature monitoring channels, compatible with RTD (resistance temperature detector, such as platinum RTD α=0.00385) and isolated tip thermocouple (TC, such as K, J, T type) inputs, and can be mixed and matched.

Measurement Range: RTD coverage -200°C to +850°C, thermocouple coverage -100°C to +1370°C depending on type, resolution 1°C/1°F, accuracy ±3°C (25°C standard environment).

Alarm Management: Dual-layer alarms (Alert/Danger) can be set via 3500 Rack Configuration Software, threshold adjustable (0-100% range), supporting TMR redundancy voting mechanism to avoid single point of failure.

Output and Communication: Front panel LED indicators (OK, TX/RX, Bypass) display real-time status, supports Ethernet/serial port communication with DCS or host computer, and integrates with the 3500 system framework for data sharing.

Signal Processing: Programmable via 3500 framework configuration software, supporting user-defined alarm thresholds (such as danger alarms, early warning setpoints), and employing a dual voting mechanism to ensure measurement accuracy and avoid single point of failure.

Redundant Design: The module supports redundant power supply configurations (such as dual AC/DC power modules) to ensure continuous system operation; the internal circuitry uses triple-redundant relay modules (such as 3500/32/33) to improve signal reliability.

Communication Capabilities: Supports RS-232/RS-422 serial ports, Ethernet, and Modbus protocols, allowing seamless integration with DCS, PLC, or host computers (such as the 3500/92 communication gateway) for remote data acquisition and status monitoring.

Core Supporting Modules

3500/05 Frame: Provides 19-inch DIN rail/panel mounting support, accommodating 14 monitor slots and power/interface modules. Supports dual power supply redundancy (3500/15) to ensure system power supply reliability.

3500/15 Power Module: Supports 24VDC redundant power supply, compliant with API 670 standards, ensuring uninterrupted operation of the mechanical protection system.

Communication and Data Interfaces

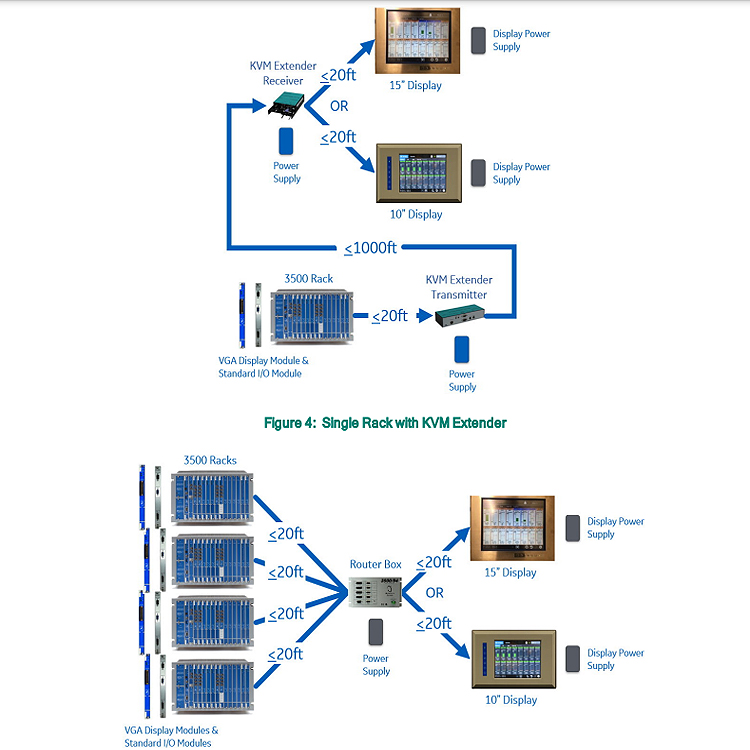

3500/22 TDI Module: Integrates transient data interface functionality, connecting to System 1 status monitoring software via Ethernet for steady-state/transient waveform data acquisition and transmission.

3500/92 Communication Gateway: Supports Modbus TCP/IP and RS-485 protocols, compatible with DCS/PLC systems (such as Siemens and ABB), enabling cross-platform data integration.

Protection and Alarm Modules

3500/32 Relay Module: Single/dual-channel alarm output, supports custom alarm thresholds, triggering equipment shutdown or maintenance signals.

3500/34 TMR Relay Module: Triple redundancy (TMR) configuration, using a 3-to-2 voting mechanism to avoid false tripping, suitable for high-safety scenarios.

Signal Processing and Expansion

External Terminal Blocks (e.g., 172115-01): Connects to monitor I/O modules via pre-engineered cables, simplifying field wiring and supporting DIN rail mounting.

3500/25 Keyphase Module: Used for speed measurement, working in conjunction with a vibration monitor to achieve comprehensive shaft system condition analysis.

Function Expansion Components:

Display and Operation Devices:

3500/93/94/95 Display Module: Provides a localized operation interface, displaying real-time temperature data, alarm status, and system events. Supports event list querying (up to 1000 alarms/400 system events).

Software Tools:

3500 Framework Configuration Software: Used for programming monitor parameters (such as alarm thresholds and filter settings), supporting module voting logic settings under TMR configuration.

System 1 Condition Monitoring Software:Enables remote monitoring, historical trend analysis, and proactive maintenance strategy deployment via the TDI module.

Sensors and Accessories:

RTD/Thermocouple Sensors: Compatible with 3-wire/4-wire RTDs (such as PT100) and isolated tip thermocouples, supporting a wide operating temperature range of -40℃ to +85℃.

Probes and Cables: Such as the 21504-00-40-05-02 proximity probe and the 21747-080-01 extension cable, suitable for scenarios such as bearing metal temperature and motor stator temperature monitoring.

System Features and Advantages

Redundant Design: In TMR configuration, three adjacent monitors ensure data accuracy through a dual voting mechanism, avoiding single points of failure.

High Precision and Real-Time Performance: Sampling rate up to 10kHz, accuracy up to ±0.1℃, supports real-time alarm triggering.

Industry Certifications: Compliant with API 670, DNV, ATEX, and other standards, suitable for harsh industrial environments such as power, petrochemical, and metallurgy industries.

Expandability: Modular design supports channel expansion (e.g., 3500/61 six-channel recorder output), adapting to diverse monitoring needs.-2.jpg)

System Integration and Configuration

Hardware Architecture: Requires use with a 3500 rack system. The rack supports modular expansion (power supply, key phase, vibration monitoring, relay modules, etc.). The power supply module supports redundant design to ensure system stability.

Software Configuration: Channel parameter settings (such as range, alarm values), data acquisition logic, and alarm interlocking strategies are completed through dedicated software. It supports integration with System 1 mechanical management software to achieve trend analysis and fault prediction.

Installation and Maintenance Points

Installation Specifications:

Probe Positioning: Vibration probes must be installed within 75mm of the bearing. For axial displacement probes, ensure the side clearance is greater than the probe radius, and the working surface must be demagnetized.

Cable Connection: Probe cables and extension cables must be sealed with dedicated connector protectors or heat shrink tubing to avoid electromagnetic interference; external terminal blocks and internal terminal modules cannot be interchanged.

Power Supply Configuration: Power supply modules (such as 3500/05) support a wide input range (85-264V AC/20-30V DC). In dual power supply mode, the main and backup power supplies automatically switch to ensure power continuity. Maintenance Process:

Daily Inspection: Check the status of the “OK” lights in each channel, the gap voltage, and the alarm setpoints to ensure there are no abnormal fluctuations.

Calibration and Verification: Regularly verify the linearity of the sensors using a Bentley TK-3E eddy current probe calibrator to ensure measurement accuracy.

Troubleshooting: If the module reports an error, initiate a self-test by shorting the self-test pins (ST 1-4) and use the error code table to locate the problem (e.g., power failure, open cable, etc.).

Daily Maintenance: Regularly clean the modules and sensors, check the tightness of the wiring terminals and the grounding of the shielding layer; at the software level, back up the configuration files and update the firmware promptly.

Common Faults:

Bypass Light On: May be caused by abnormal channel voltage, loose wiring, or probe failure. Check the voltage value, inspect the connectors, and replace any damaged parts.

DCS Display Abnormalities: May be caused by signal interference, probe wear, or grounding problems. Check the shielding layer connection, replace the probe, or adjust the gap voltage.

Redundancy Design: Under the TMR configuration, the three modules ensure data consistency through a voting mechanism. A single module failure does not affect overall operation. Regular self-checks and error code clearing are required.

System Integration and Application Scenarios

System Architecture: Part of the 3500 monitoring system framework, it can work collaboratively with key phase modules (e.g., 3500/20), relay modules (e.g., 3500/32/33), and communication gateways (e.g., 3500/92) to form a complete mechanical protection network.

Typical Applications:

Power Industry: Temperature monitoring of turbine and generator bearings to prevent overheating and equipment damage.

Petrochemical Industry: Synchronous monitoring of vibration and temperature in compressors and pumps for early fault warning.

Metallurgical Industry: Combined temperature and displacement monitoring in high-temperature environments such as blast furnace blowers and rolling mills.

Explosion-proof Requirements: In hazardous environments containing ammonia, hydrogen, etc., a gas-filled explosion-proof design is required, and the probe connector must be fitted with a protective layer.

Industry Applications and Value

Typical Scenarios: Widely used in industries such as power, petrochemicals, and metallurgy to monitor key parameters such as turbine bearing temperature and compressor cylinder temperature, preventing equipment damage caused by overheating.

Advantages: High reliability, resistance to harsh environments (such as high temperature and vibration), seamless integration with DCS, support for predictive maintenance, reduced risk of unplanned downtime, and extended equipment lifespan.

Summary: The Bently Nevada 3500/65-01-00 145988-02 temperature monitoring module, with its core features of high precision, high reliability, and modular design, is suitable for full lifecycle condition monitoring of industrial rotating machinery. Its installation, maintenance, and system integration must strictly adhere to Bently’s patent specifications and be optimized for specific operating conditions to ensure safe and efficient equipment operation.

Please note that all products on this website are specialty items, and market prices are constantly fluctuating.

Please refer to customer service for a specific quote, as the price may not be accurate for new products.

Please confirm the model, product, price, and other details with customer service before placing an order. This website is currently in use.

New items are available for sale; please contact customer service for further information.

Recommended related products:

Bently Nevada 3500/22M 138607-01 Transient Data Interface (TDI) module

Bently Nevada 3500 Series rack-mount system

Bently Nevada 3500/45 176449-04 Position Monitor

Bently Nevada 3500/92 Communication Gateway

Bently Nevada 3500/42 Proximitor Seismic Monitor

Bently Nevada 3500/15 Power Supply

Bently Nevada Transient data interface module 3500/22M

BENTLY 133388-01 AT LO161204-01 3500/9

BENTLY NEVADA 3500

BENTLY 3500/15 127610–01

BENTLY 1900/65A-00–00–02–00–01

BENTLY 3500/40M

BENTLY ASSY78462-01

BENTLY 3500/42M

BENTLY 3500/65

125720-01 BENTLY

More……

admin –

Alarm Management: Dual-layer alarms (Alert/Danger) can be set via 3500 Rack Configuration Software, threshold adjustable (0-100% range), supporting TMR redundancy voting mechanism to avoid single point of failure.

Output and Communication: Front panel LED indicators (OK, TX/RX, Bypass) display real-time status, supports Ethernet/serial port communication with DCS or host computer, and integrates with the 3500 system framework for data sharing.

Signal Processing: Programmable via 3500 framework configuration software, supporting user-defined alarm thresholds (such as danger alarms, early warning setpoints), and employing a dual voting mechanism to ensure measurement accuracy and avoid single point of failure.

Redundant Design: The module supports redundant power supply configurations (such as dual AC/DC power modules) to ensure continuous system operation; the internal circuitry uses triple-redundant relay modules (such as 3500/32/33) to improve signal reliability.

Communication Capabilities: Supports RS-232/RS-422 serial ports, Ethernet, and Modbus protocols, allowing seamless integration with DCS, PLC, or host computers (such as the 3500/92 communication gateway) for remote data acquisition and status monitoring.

https://www.weikunfadacai1.com/product/bently-3500-65/