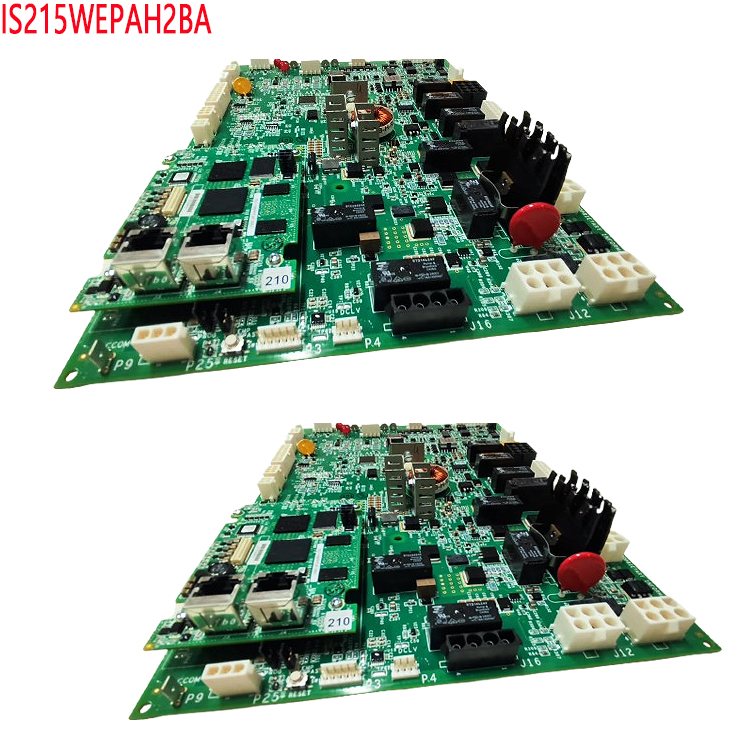

Description

Many products are not yet listed. Please contact us for more product information.

If the product model differs from the displayed image, the model number shall prevail. Please contact us for specific product images; we will arrange to take photos in our warehouse for confirmation.

We have 76 shared warehouses worldwide, so it may sometimes take several hours to accurately return the information to you. We apologize for any inconvenience. Of course, we will respond to your inquiries as soon as possible.

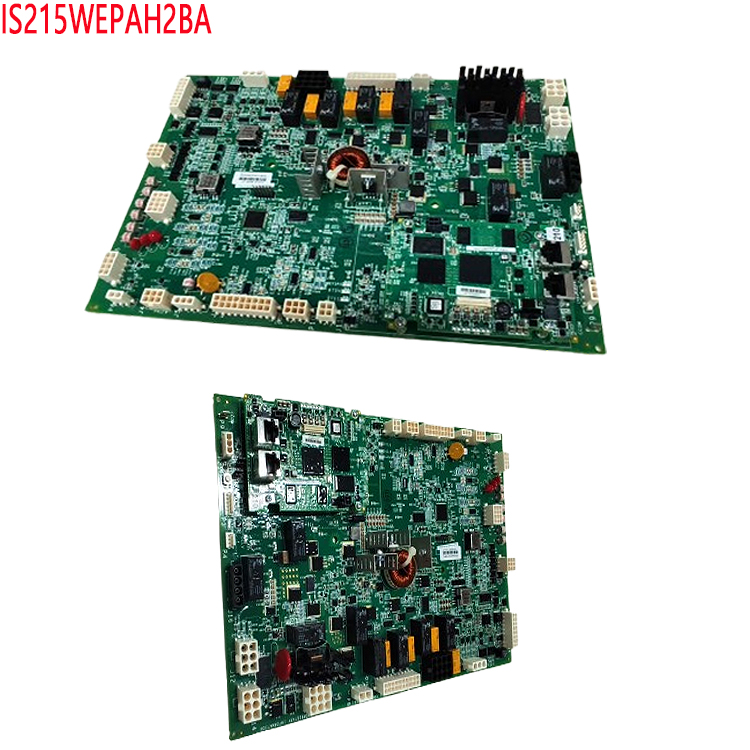

Interface Layout: Includes power input, control signal interface, sensor interface (such as flame sensor, oil pressure/oil temperature monitor), actuator drive interface (blower, oil quantity regulator), and communication port (RS485/Ethernet). Supports expansion TF card (≤32GB) and external Bluetooth module (HCO5).

Typical interfaces include analog/digital signal acquisition, communication bus (such as CAN, EtherCAT), power management module, and actuator drive circuit.

Core Functional Modules

Combustion Control: Achieves efficient atomization and combustion optimization of fuel/gas through a rotor atomizer and fuel regulating unit, matching boiler load regulation (such as 1-10 level automatic adjustment).

Safety Protection: Integrates low water level alarm, flameout protection, air pressure monitoring, overvoltage/overcurrent protection, and other safety devices to ensure safe boiler operation.

Communication and Networking: Supports industrial communication protocols (such as Modbus and Profibus) to achieve data interaction with host computers (SCADA/HMI) or the cloud.

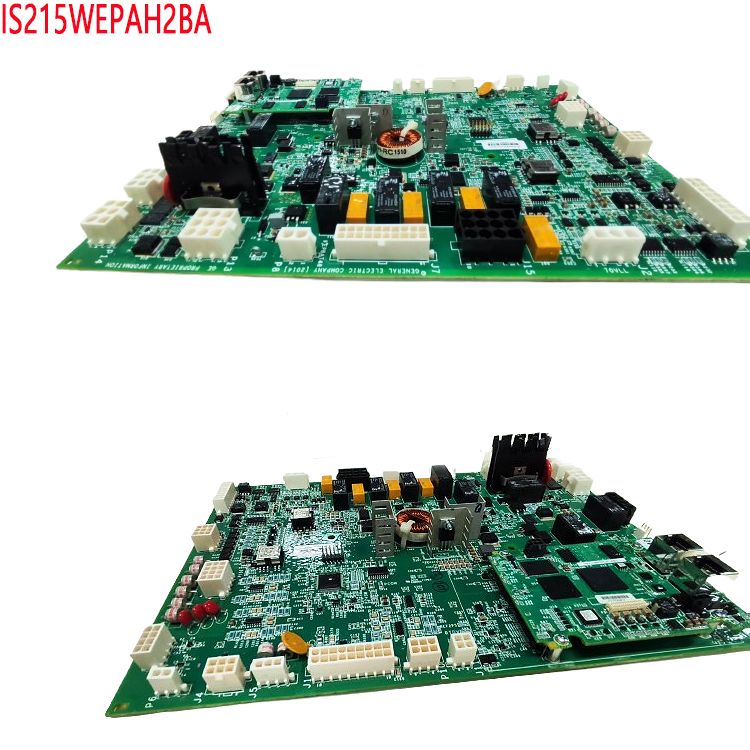

Power Management: Built-in DC-DC converter and LDO regulator convert industrial power (24VDC/220VAC) to multiple voltage outputs (such as 5V, 3.3V, ±15V) required by the onboard chips.

Common Faults and Solutions

Rotor Atomization System Faults:

Oil Leakage and Carbon Deposition: Caused by insufficient primary air volume, rotor extension distance exceeding specifications (factory setting 1mm, maximum 3mm), or excessive fuel flow. Clean the oil sludge in the rotor/atomizing hood’s inner ring groove, adjust the rotor extension distance to 1mm, increase the tertiary air channel cross-section, and reduce the fuel flow rate under low load (e.g., reduce from 42L/H to 37L/H at speed 1).

Ignition Difficulty: Ignition electrode position misalignment (standard distance from orifice plate 3mm), poor fuel atomization, or excessively high secondary air pressure (≤20mbar during ignition). Adjust the electrode position to 3mm, clean electrode carbon deposits, tighten the distributor cone positioning screws to reduce the secondary air passage, and clear the fuel distributor outlet (approximately 3mm diameter).

Combustion Abnormalities and Flue Gas Problems:

Furnace Carbon Deposition: Excessive atomization angle (guide vane angle needs to be reduced from 30° to 10°), insufficient tertiary air, or excessive fuel viscosity (heavy fuel needs ≥90℃/≤45mm²/s). Adjust the guide vane angle, increase the tertiary air inlet gap, and periodically shut down the furnace for purging to remove carbon deposits.

Flue Gas Blockage: Ash accumulation in the flue, unburned oil droplet deposition, or fan belt slippage. Clean the flue with water every 3 months, check fan belt tension monthly, and clean the fuel distributor and install a 10μm pre-filter every 15 days.

Replacement Parts and Maintenance Guidelines

Key Replacement Parts

Core Components: Microprocessor (CPU/MCU), Memory (RAM/Flash), ADC/DAC converter, Isolation chip (optocoupler/magnetic coupler), Driver circuit (MOSFET/IGBT).

Interface Modules: Communication controller (e.g., CAN transceiver), connectors, terminal blocks. Must match original manufacturer specifications to ensure compatibility.

Safety Devices: Safety valves, water level sensors, flame detectors, pressure/temperature monitors. Must be calibrated regularly and comply with classification society/industry standards.

Maintenance and Repair Points

Safe Operation: Operate after power is off. Wear an anti-static wrist strap and use an anti-static workbench to avoid ESD damage to sensitive components.

Fault Diagnosis: Use a multimeter and oscilloscope to test voltage/signal waveforms to troubleshoot short circuits, cold solder joints, component failures, etc.

Specialized Tools: Hot air gun (320℃±20℃), desoldering pump, microscope. Used for desoldering surface mount components and inspecting minute solder joint defects.

Software Support: Some models require firmware updates using the official firmware upgrade tool (such as the embedded BS splicer configuration software).

Maintenance and Care Points

Daily Maintenance: Monitor fuel pressure (2 bar for light fuel/4 bar for heavy fuel), fuel temperature (60-80℃ for light fuel/90-120℃ for heavy fuel), air pressure (≥15mbar), and flue gas temperature (≤200℃) daily. Check for oil leaks and carbon buildup in the rotor/distributor. Test the safety shut-off function of the flame monitoring system (effective within 1 second). Clean the flame sensor lens and observation port glass.

Regular Maintenance: Check the ignition electrode’s ignition status and belt cracks weekly. Clean the fuel regulating unit valve core monthly, lubricate the blower/rotor motor bearings (high-temperature grease), and measure the motor insulation resistance (≥1MΩ). Wash the flue with water quarterly, adjust the rotor extension distance and fuel quantity regulator connecting rod length. Disassemble the fuel regulating unit annually, replace the sealing gasket, calibrate the air-fuel ratio (O₂ content 3-5%), and replace the refractory bricks at the furnace conical inlet. Please note that all products on this website are specialty items, and market prices are constantly fluctuating.

The exact price quoted by customer service will prevail, as the price may not reflect the actual product.

Please confirm the model, product, price, and other details with customer service before placing an order. This website is currently in use.

New items are available for sale; please contact customer service for further information.

Recommended related products:

TERASAKI ERB-324-K-751-3-002BZ-342

TERASAKI ERB-324-K-751-3-002A-341

TERASAKI ERB-117A-K-751-9-001B-32

TERASAKI EMW-1501 K-827-2-001A 2

TERASAKI EMW-1401A K-821-4-001C

TERASAKI EMW-1301 K-821-3-001C

TERASAKI EMI-502 K-787-18-001B

TERASAKI EMI-501 K-787-17-001A

TERASAKI EMI-301 K-787-11-001A

More……

Reviews

There are no reviews yet.