Description

Many products are not yet available. Please contact us for more information.

If the product model number differs from the displayed image, the model number will prevail. Please contact us for specific product images, and we will arrange for photos to be taken at the warehouse for verification.

We have 76 shared warehouses worldwide, so it may sometimes take several hours to accurately return your order. We apologize for this. Of course, we will respond to your inquiries as soon as possible.

Other names for the 3BHB009885R0021:

Advanced High-Voltage Converter Module 3BHB009885R0021

3BHB009885R0021 Standard Pulse Module

MV High-Pulse Phase Module 3BHB009885R0021

3BHB009885R0021 Standard Pulse Phase Module

MVA Phase Module 3BHB009885R0021

The ABB PCS6000 power supply system phase module 3BHB009885R0021 is a core component of a modular medium-voltage power conversion system designed for high-power industrial and renewable energy applications. Based on IGCT (Integrated Gate-Commutated Thyristor) technology, this module supports four-quadrant bidirectional power flow, covers a power range of 4-120 MVA, boasts an efficiency exceeding 98%, and utilizes a dual-mode (air/water) closed-loop cooling system. Designed specifically for high-power industrial and renewable energy applications (such as wind farms and grid stabilization control). The module utilizes IGCT (Integrated Gate Commutated Thyristor) technology, supports four-quadrant bidirectional power flow, and boasts >98% efficiency.

Technical Parameters

Power and Voltage: The module supports a power range of 4-120 MVA, suitable for voltage levels of 3.3 kV and below, and supports wind turbines up to 14 MW.

Efficiency and Cooling: Utilizing IGCT technology, it boasts >98% efficiency, and its cooling system supports both air and water cooling, making it suitable for harsh industrial environments.

Control and Interface: Based on the ABB AC800PEC PLC platform, it utilizes sensorless algorithms and supports industrial communication protocols such as Profibus DP, Modbus TCP, and EtherCat.

Protection: Built-in overload, short-circuit, overvoltage, and grid fault ride-through protection ensures stable system operation.

Electrical Performance:

Wide input voltage range (85-264V AC), compatible with 50/60Hz power grids, frequency range 47-63Hz.

Efficiency ≥92%, high-frequency switching technology reduces heat loss, and supports dual air/water cooling.

Built-in overvoltage, overcurrent, short-circuit, and overtemperature protection, with rapid fault isolation capabilities (such as grid breaker unit (GBU) functionality).

Physical and Interface:

Modular design supports DIN-rail/rack mounting, and hot-swappable functionality facilitates maintenance.

Compatible with industrial communication protocols such as Profibus-DP and Modbus, it can be connected to a PLC or SCADA system for remote monitoring and diagnostics.

Operating temperature range -25°C to +60°C, compliant with IEC 61850/60255 industrial standards, suitable for harsh environments.

Control Logic:

Based on ABB Direct Torque Control (DTC) technology, it achieves real-time, precise control of motor torque and speed.

It supports connecting multiple motors to a common DC bus, enabling braking energy recovery and reuse, and reducing grid energy consumption.

Phase Control Core: This module is a key component of medium-voltage power conversion systems (such as the ACS6000/PCS6000). It is responsible for precisely regulating the phase synchronization of voltage and current, ensuring stable operation of motors/equipment under complex operating conditions (such as sudden load changes and grid fluctuations), improving energy conversion efficiency, and reducing energy consumption.

System Integration Role: In the PCS6000, the phase module works in conjunction with IGCT (Integrated Gate Commutated Thyristor) modules, excitation controllers, and PLC control units (such as the AC 800PEC). It supports modular expansion (single module power range of 4-120 MVA) and is suitable for high-power scenarios such as wind power, metallurgy, and mining.

Phase Regulation and Dynamic Control: This module implements dynamic voltage control, fault ride-through, and reactive power compensation in STATCOM (static var generator), meeting grid code requirements for wind power integration (such as voltage fluctuation suppression and frequency regulation). Protection: Built-in overload, short-circuit, overvoltage, and overtemperature protections, along with redundant configuration (seamless backup module failover in the event of a primary module failure) ensure continuous system operation.

Communication and Compatibility: Supports industrial protocols such as PROFIBUS DP, Modbus TCP/IP, and EtherCat, enabling interconnection with ABB 800xA and AC 800M control systems and third-party equipment (such as Siemens and Omron).

Structure and Design

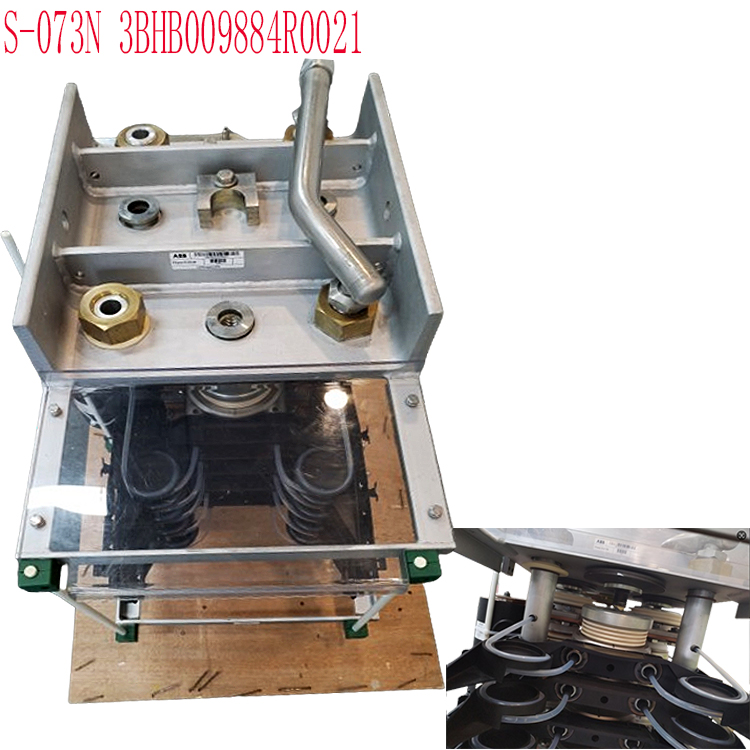

Modular Architecture: Utilizing an expandable power electronics module (PEBB) design, it supports flexible configuration to meet diverse application requirements.

Compact Design: Weighing approximately 0.69 kg, its compact size facilitates integration into the PCS6000 system.

High Reliability: Compliant with international standards such as IEC 61850 and IEC 60255, it withstands harsh environments such as high temperature, humidity, and vibration, with an MTBF (mean time between failures) exceeding 100,000 hours.

Application Scenarios

Industrial Drive Systems

Multi-Motor Synergy: In steel mills, mining crushers, and other applications, this system synchronizes multiple motors through a common DC bus, optimizing energy flow.

Dynamic Regulation: In equipment such as fans, pumps, and compressors, precise phase control improves efficiency and reduces energy consumption.

Renewable Energy

Wind Power Conversion: In wind power generation systems, this system serves as a core component of the STATCOM (static var generator), supporting grid code compliance and improving power quality.

Grid Compensation: Ensures power system stability and reliability in scenarios such as grid fault ride-through and dynamic voltage regulation.

Special Industries

Chemical and Metallurgical: High protection ratings (e.g., IP54) ensure long-term stable operation in high-temperature and highly corrosive environments.

Power Transmission: Supports high-power power conversion and distribution in HVDC and Flexible AC transmission systems.

Maintenance and Troubleshooting

Daily Maintenance

Regular Inspections: It is recommended to perform a system inspection every six months, including the cooling system, electrical connections, and module status.

Cleaning and Maintenance: Use a dedicated cleaning tool to clean the module surface to prevent dust accumulation that could affect heat dissipation.

Troubleshooting

Common Problems: Module overheating, communication failures, abnormal output, etc.

Solutions:

Overheating: Check the cooling system for unobstructed operation and clean the heat sink surface.

Communication Failures: Verify the communication protocol settings (e.g., Profibus address, baud rate) and check the cable connections.

Abnormal Outputs: Use ABB Control Builder or Automation Builder to calibrate parameters and diagnose faults.

Related Modules and Expandability

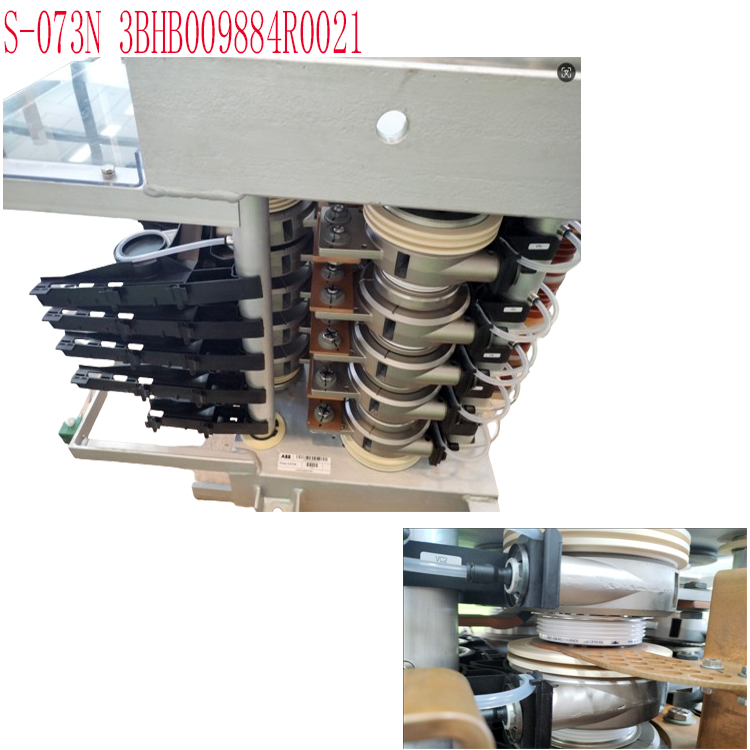

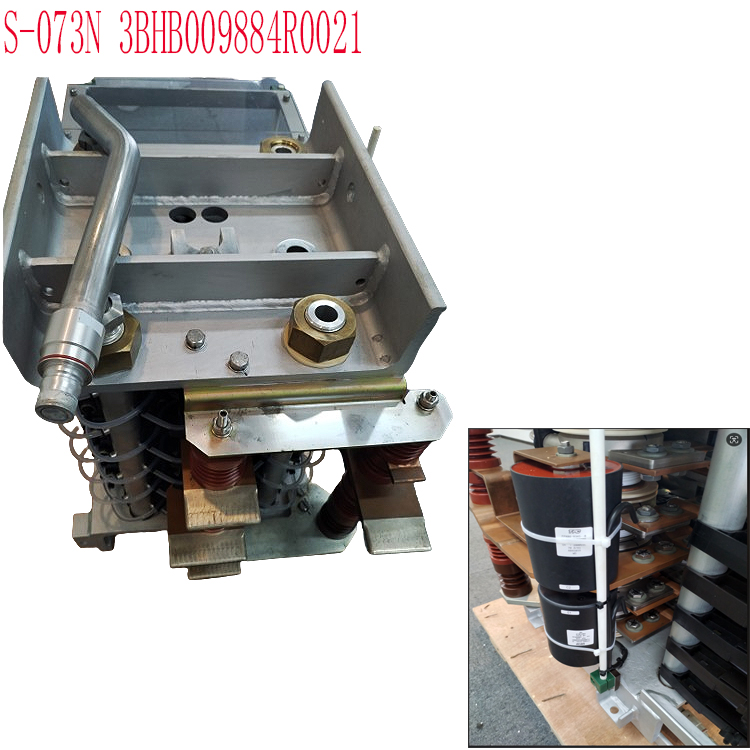

Modules in the same series, such as the S-073N (phase controller) and S-093H (IoT module), can be combined to enhance system functionality (e.g., data acquisition, remote monitoring).

Expandability: Supports modular design and can be integrated with components such as IGCTs, thyristors, and excitation controllers to meet diverse application requirements.

Installation and Maintenance Key Points

Installation Specifications: Follow modular design principles, ensure proper electrical connections (e.g., matching connectors and reliable grounding), and configure redundant power supplies and protection circuits.

Maintenance Recommendations: Regularly check module status (e.g., LED indicators and heat dissipation), and use ABB official tools (e.g., Control Builder) for parameter configuration and troubleshooting. Module failures can be quickly replaced, minimizing downtime.

Application Scenarios and Industry Case Studies

Typical Applications: Wind turbine converters, industrial motor drives, grid energy storage systems, and automated production lines.

Case Study: A high-skilled training base in Inner Mongolia purchased this module for welder training, emphasizing its high power load capacity and stability.

Summary

The ABB PCS6000 power supply system phase module 3BHB009885R0021, with its high power density, high efficiency, and modular design, demonstrates outstanding performance in industrial drives, renewable energy, and power transmission. Through precise phase control and powerful protection features, this module effectively improves system stability and energy efficiency.

All products on this website are special editions, and market prices are constantly fluctuating.

Please refer to customer service for specific quotes. Since these products are new, prices are not official.

Please confirm model, product, price, and other details with customer service before placing an order. This website is used.

New products are currently available for sale, so please contact customer service.

Related product recommendations:

S-093H 3BHB030478R0009

S-093M 3BHB009885R0013

S-093R 3BHB009885R5311

S-097H 3BHB009885R0052

S-093M 3BHB009885R0063

ABB S-093H 3BHB030478R0309

ABB S-093S 3BHB030475R0009

S-093S 3BHB030475R0009

S-073N 3BHB009884R5211

S-073N 3BHB009884R0021 35SHY3545L0014

S-053M 3BHB012897R0003

S-073N 3BHB009884R0021 35SHY3545L0014

S-073N ABB 3BHB009884R0021

S-097H 3BHB009885R0052

S-093H 3BHB030478R0309

More……

-300x300.jpg)

admin –

3BHB009885R0021 | ABB | PCS6000 Power Supply System | Phase Module | 3BHB009885R0021

3BHB009885R0021

https://www.weikunfadacai1.com/product/3bhb009885r0021-abb-pcs6000-power-supply-system-phase-module-3bhb009885r0021/| ABB | PCS6000 Power Supply System | Phase Module | 3BHB009885R0021

3BHB009885R0021 | ABB ACS6000 Power Supply System Phase Module Technical Analysis

Core Positioning and Technical Architecture

System Affiliation: This module belongs to the S-093N series phase module of the ABB ACS6000/PCS6000 medium-voltage power supply system, suitable for power ranges from 3 to 36 MW and voltage levels of 3.3 kV. Its modular design supports hot swapping and is compatible with common DC bus architectures, making it suitable for industrial drives, electric power, and rail transit applications.

Control Core: This module integrates IGCT technology, adopts a three-level VSI-NPC topology, and features a fuse-free design with an efficiency of ≥92%. It supports four-quadrant operation (bidirectional energy flow). Direct Torque Control (DTC) technology delivers millisecond-level torque/speed response and is compatible with 50/60 Hz power grids.

Cooling and Protection: The dual-mode cooling system (forced air cooling and liquid cooling) adapts to high-temperature, high-humidity, and vibration environments. It offers IP20 protection (expandable to IP54). Operating temperature range -25°C to +70°C, interrupting capacity up to 31.5kA, compatible with standard 19-inch cabinet installation.

Key Features and Technical Parameters

Power Quality and Grid Compatibility: Dynamic voltage control, reactive power compensation, and fault ride-through (FRT) are implemented in STATCOM mode, meeting grid regulations such as low voltage ride-through (LVRT). Total harmonic distortion (THD) <3%, supporting 85-264V AC input, and compatible with various global grid standards. Certified by CGC (GB/T 25387-2010) and DNV-GL (GL-IV-2:2012), the system meets the requirements of offshore wind power projects.

Efficiency and Protection: Converter efficiency at rated point ≥ 92%, built-in overvoltage, overcurrent, short-circuit, and overtemperature protection, and an MTBF exceeding 100,000 hours. The system supports overload, short-circuit, and overvoltage protection, as well as rapid fault isolation and ground fault protection.

Expandability: Supports customized power requirements, is compatible with industrial protocols such as Modbus TCP/IP, PROFIBUS-DP, and Ethernet/IP, and is suitable for multi-motor coordinated operation and energy recovery scenarios.

Special Application Configurations: Provides optimal efficiency in gearless mill drives (GMDs) in mining; adapts to 14MW turbines in the wind power sector, meeting the high-temperature and high-humidity requirements of offshore wind power; and implements dynamic reactive power compensation (20-100 Mvar) in grid support, improving power transmission capacity.

Application Scenarios and Advantages

Industrial Applications: Widely used in high-voltage inverters, motor control, power supply control, and automatic control systems. For example, it enables stable operation under extreme operating conditions in pump motors; implements dynamic temperature control in cooling fans to reduce energy consumption; and ensures phase synchronization in wind turbine pitch systems.

System Advantages:

High Reliability: IGCT technology reduces component count, extends service life, and reduces failure rates. Certified to SIL 3 (IEC 61508) and PLe (ISO 13849) safety levels.

Low Lifecycle Cost: Modular maintenance reduces downtime, and remote monitoring supports predictive maintenance.

Environmental Adaptability: Dual-mode cooling and a dust- and water-resistant design are suitable for harsh environments such as mines and offshore platforms.

Grid Compatibility: Complies with international standards such as IEEE 519, supporting dynamic voltage control and fault ride-through.

Maintenance and Troubleshooting

Daily Maintenance: Regularly check module status (LED indicators, heat dissipation), DC bus voltage, and filter status. It is recommended to thoroughly check capacitor status and gate voltage every 5,000 hours, clean the air filter every 6-12 months, and replace the cooling fan every three years.

Troubleshooting:

Common Faults: Overvoltage/overcurrent, IGCT damage, communication interruption, and cooling system failure.

Handling Procedure: Locate the faulty module based on the fault code and replace the faulty module via hot-swapping. Use a multimeter or oscilloscope to monitor the gate voltage and current waveforms. Analyze the fault logger data using DriveWindow software. For example, in a coal mine hoist failure, by checking the IGCT and diode performance, the instability of the clamping diode VC1 was located, and normal operation was restored after replacement.

Spare parts management: Use genuine ABB parts (such as the 3BHB011219R0001 capacitor and the 3BHB018008R0101 phase module) to ensure compatibility.