Description

Many products are not yet available. Please contact us for more information.

If the product model number differs from the displayed image, the model number will prevail. Please contact us for specific product images, and we will arrange to take photos at the warehouse for verification.

We have 76 shared warehouses worldwide, so it may sometimes take several hours for us to accurately return your product. Please understand. We will, of course, respond to your inquiries as soon as possible.

Other names for 3BHB906001446:

Medium- and high-voltage thyristor phase module 3BHB906001446

3BHB906001446 high-voltage inverter module

System Overview

Product Positioning: The ACS6000 is a modular medium-voltage inverter from ABB, designed for high-precision speed/torque control of 5-36MW motors. It is widely used in industrial applications such as steel, mining, shipbuilding, and wind tunnel testing.

Core Technology: Utilizes Direct Torque Control (DTC) technology, achieving real-time control at 40,000 times per second, with a dynamic response time as low as 1-2ms, supporting four-quadrant operation and field weakening control (up to a 1:5 speed ratio).

Power Module: Based on a 3-level topology using IGCTs (Integrated Gate Commutated Thyristors), this fuseless design offers an adjustable power factor of ±1.0 and an efficiency of >98%.

Core Function: Enables efficient energy conversion and stable operation of motors by precisely controlling the voltage/current phase. For example, in equipment such as rolling mills, crushers, and hoists, this ensures phase consistency during synchronous operation of multiple motors, reducing vibration and energy consumption, and extending equipment life.

Technical Features:

High-Precision Detection: Utilizes advanced phase detection circuitry to capture subtle phase changes in real time, achieving industrial-grade accuracy.

Fast Response: Based on DTC (Direct Torque Control) technology, response times as low as 1-2ms are achieved, adapting to sudden load changes.

Wide operating temperature range: Supports ambient temperatures from -25°C to 60°C, tolerates voltage fluctuations of ±10%, and operates at altitudes up to 2000 meters without derating.

Core Technologies and Parameters

System Architecture

Modular design: Includes active rectifier unit (ARU), inverter unit (INU), capacitor unit (CBU), control unit (COU), and water cooling unit (WCU). Supports common DC bus configuration and is scalable to multiple motor drive systems.

Power range: 3000-36000kW, output voltage 2.3kV/3.3kV, frequency 0-75Hz (high-speed models up to 250Hz).

Efficiency and Power Factor: Efficiency >98%, input power factor >0.95 (diode rectifier) or adjustable to 1.0 (active rectifier), output power factor 1.0 for synchronous motors and 0.84 for induction motors.

Control Technology: Direct Torque Control (DTC) with a 25μs response time, supports four-quadrant operation, achieves dynamic torque accuracy of 0.1%, and speed control accuracy of ±0.01%.

Input Specifications:

Voltage: 6/12/24-pulse diode rectification (3300V) or 12/18-pulse active rectification (3160V), supports ±10% voltage fluctuation (derating range: ±15%/-30%).

Frequency: 50/60Hz, fluctuation range: ±5%.

Output Specifications:

Power: 3-36MW, voltage 2.3/3.3kV, frequency 0-75Hz (scalable).

Motor Compatibility: Supports induction motors, synchronous motors, and permanent magnet synchronous motors.

Environmental Adaptability:

Protection Level: IP32 (standard), IP42/IP54 optional.

Operating Temperature: 0-40°C (higher operating temperature with derating), Altitude: 0-2000 meters (higher operating temperature with derating).

Key Component Features

IGCT Technology: Integrated gate-commutated thyristors (GTCs) combine the high-speed switching characteristics of IGBTs with the low conduction loss characteristics of GTOs, supporting 6-pulse, 12-pulse, and 24-pulse rectification. Harmonics comply with IEC 61000-2-4 and IEEE 519 standards.

Modular Architecture: The ACS6000 utilizes a standardized module combination, including:

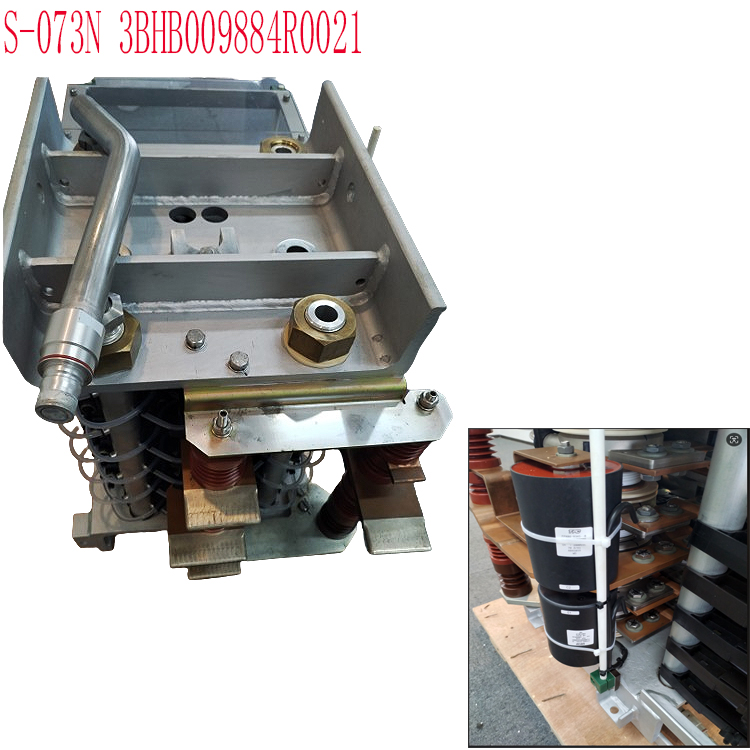

INU (Inverter Unit): 3-11MVA power modules utilizing a 3-level voltage source topology with integrated IGCTs (Integrated Gate Commutated Thyristors) and di/dt filters.

ARU (Active Rectifier Unit): Built-in IGCTs, supports 4-quadrant operation, and has a power factor adjustable to ±1.0.

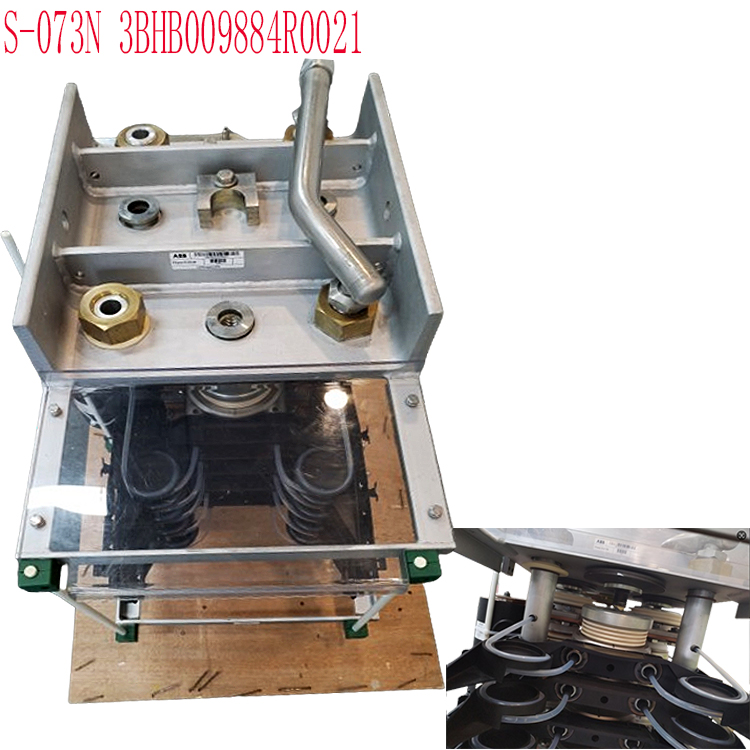

WCU (Water Cooling Unit): Enclosed cooling system adapted to the heat dissipation requirements of different power modules.

Key Parameters:

Input Voltage Range: 6-24 pulse rectifiers are compatible with 3300V/1725V, active rectifiers support 3160V.

Output Frequency: 0-75Hz, compatible with induction, synchronous, and permanent magnet motors.

Efficiency: >98%, harmonics comply with IEC 61000-2-4/IEEE 519 standards.

Cooling System: Closed water-cooling design with deionized water circulation, external cooling water temperature 5-32°C (derating up to 40°C), flow rate 250-300L/min, pressure 2-5 bar, differential pressure ≤1.5 bar.

Protection Functions: Overvoltage/undervoltage protection, overcurrent protection, ground fault detection, temperature monitoring (IGCT, diode, cooling water), and power failure ride-through (maintaining operation during voltage drops).

Application Scenarios and Case Studies

Industrial Sector

Metallurgy and Mining: Used in blast furnace blowers (e.g., the SSAB Oxelosund project, saving 16GWh annually), mine hoists, rolling mills, and extruders.

Oil and Gas: Compressor drives (e.g., the 48MW drive system for the Ormen Lange subsea natural gas field) and pumped storage drives.

Power and Chemical: Pump and fan speed control (e.g., the NASA wind tunnel project, where a 101MW VFD drives a 135,000hp synchronous motor), wastewater treatment, and chemical process control.

Special Scenarios

Marine Propulsion: Main and auxiliary propulsion systems, supporting 6-pulse and 12-pulse rectification to withstand harsh offshore environments.

Aerospace: The NASA supersonic wind tunnel project achieved Mach 1 wind speed simulations with Reynolds numbers exceeding 100 million.

Maintenance and Commissioning Key Points

Daily Maintenance

IGCT and Diode Inspection: Use a multimeter to measure the gate-to-cathode voltage (-20VDC/+0.7VDC). Connect to the control board via an optical cable. Always disconnect the power cord and ground the power cord to avoid short circuits.

Cooling System Maintenance: Regularly check the cooling water conductivity, pressure, and temperature, clean the cooling plate, and replace the deionized water (typically every two years).

Module Replacement: Phase modules (e.g., 3/5MVA) require specialized tools and follow the power-off, discharge, and grounding procedures. Recalibrate the motor model parameters after replacement.

Commissioning Process

Cold Commissioning: Check the installation dimensions, cable connections, grounding system, and cooling water circuits, and verify the auxiliary power supply and control signals.

Hot Commissioning: Perform load testing, calibrate the motor model parameters (equivalent circuit and saturation model), verify DTC control performance (torque response, speed accuracy), and perform overload and fault simulation tests.

Parameter Optimization: Adjust the power factor, harmonic filter, and brake resistor configuration based on load characteristics to optimize energy efficiency and dynamic performance.

Industry Standards: Complies with electromagnetic compatibility and harmonic standards such as IEC 61000-2-4 and IEEE 519, and is CE and UL certified.

Case Studies: Actual application cases such as the NASA wind tunnel project, SSAB blast furnace renovation, and the Ormen Lange natural gas field verify system reliability and energy efficiency.

Maintenance and Troubleshooting

Routine Maintenance:

IGCT/Diode Testing: Use a multimeter to measure the gate-to-cathode voltage (normal values are -20VDC/+0.7VDC). Regularly check the clamping diode (such as VC1) and the insulation performance of the copper busbar.

Cooling System: The water-cooling unit requires monitoring of conductivity, pressure (2-5 bar), and temperature (5-32°C). Replace the deionization tank every two years.

Grounding Operation: Before operation, ensure that the grounding disconnect switch is in the ungrounded state. Emergency stop resets require sequential operation on the COU1/COU2 control panels.

Regular Inspections: Use a multimeter to test the IGCT gate-to-cathode voltage (-20VDC/+0.7VDC) and observe the LED status; use a Megger test to test the diode insulation.

Software Tools: Use DriveWindow software to store fault/data logger content and analyze fault chains (e.g., INU/ARU module abnormalities).

Cooling System: Monitor the water cooling unit flow rate (250-300L/min), pressure (2-5 bar), and conductivity to ensure the quality of the deionized water.

Common Faults and Solutions:

Overcurrent/Di/Dt Faults: Caused by unstable IGCT performance, clamping diode failure, or copper discharge. Replace the faulty module and test the phase module insulation.

Abnormal DC bus voltage: Check the charging circuit, balancing resistors, and capacitors to ensure the voltage is stable around 4840V.

Excessive conductivity: Replace the ion filter, clean the water pipes, and reset the valve.

Encoder Fault: Reposition the encoder and calibrate the torque/speed feedback signals.

Phase loss: Check the power line contact, motor winding condition, and internal controller components (such as capacitors and resistors).

Overvoltage/undervoltage: Troubleshoot grid fluctuations, sudden load changes, or braking energy regeneration paths (such as common DC bus energy recovery).

IGCT fault: Test the gate unit via optical cable. When replacing a faulty module, ensure the capacitor is discharged (wait 20 seconds) to avoid short circuits.

Typical Application Cases

Steel Industry: Used in rolling mill main drives, achieving high-precision torque control (dynamic accuracy <1%) and supporting rapid start and stop (such as quick stop buttons and emergency stop resets).

Mine Hoisting: In coal mine main shaft hoists, ARUs (active rectifier units) achieve four-quadrant operation, eliminating frequent tripping.

Metallurgical Industry: In rolling mill drives, phase controllers ensure multi-motor synchronization, reduce rolling force fluctuations, and improve steel quality.

Energy sector: Demonstrating high reliability and energy savings, such as in NASA wind tunnel projects (101MW inverters) and blast furnace blowers (saving 16GWh/year).

Common DC bus: When multiple motors operate in coordination, braking energy is re-used through the bus, reducing grid energy consumption. A typical example is elevator group control systems.

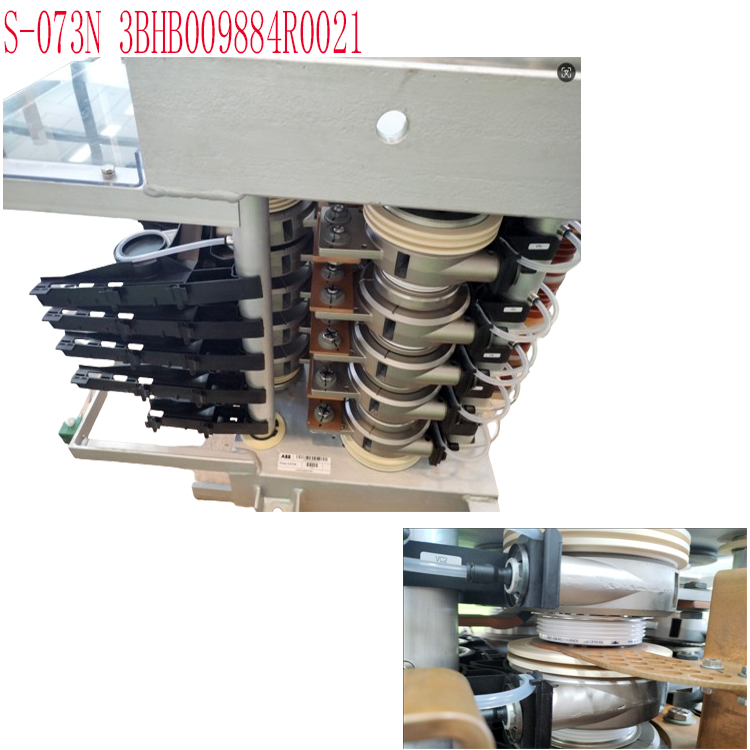

Comparison with the same series: Phase modules such as the S-073N outperform basic models in accuracy and response speed, making them suitable for applications requiring stringent phase control (such as precision rolling).

Operation and Commissioning Key Points

Power Supply Process: Confirm the status of the control power supply and grounding switch, and perform closing/emergency stop operations through the console or COU panel.

Fault Diagnosis: Use DriveWindow software to analyze fault logs (such as EPLD First Fault) and combine datalogger traces to locate the root cause.

Module Replacement: Follow safety regulations and use specialized tools (such as hoists or cranes) to remove/install phase modules to avoid short-circuit risks.

Advantages and Limitations

Advantages: High power density, low harmonics (compliant with IEC 61000-2-4/IEEE 519), modular design for easy maintenance, and remote diagnostics.

Limitations: Requires high cooling system requirements; derating is required for high-altitude/high-temperature environments; some faults require specialized handling.

Summary

As a core component of ABB’s medium-voltage drive system, the ACS6000 phase controller 3BHB906001446, with its modular design, efficient DTC control, wide application compatibility, and stringent maintenance standards, is a high-performance solution for industrial drives, suitable for high-precision, high-dynamic, and high-reliability electric drive scenarios.

All products on this website are special products, and market prices are constantly fluctuating.

Please refer to customer service for specific quotes. Since these products are new, prices may not be accurate.

Please confirm model, product, price, and other details with customer service before placing an order. This website is used.

New products are for sale. Please contact customer service for inquiries.

Related product recommendations:

S-073H 3BHB009884R0002

S-073H 3BHB009884R0004

S-073M 3BHB009884R0013

S-073H 3BHB009884R0052

S-073H 3BHB009884R0004

S-073M 3BHB009884R0013

S-073H 3BHB009884R0052

S-073H 3BHB009884R0204

S-093H 3BHB009885R0002

S-093H 3BHB009885R0004

S-093M 3BHB009885R0014

S-093S 3BHB009885R0031

S-093H 3BHB009885R0104

More……

-300x300.jpg)

admin –

Technical Positioning and Functions

System Role: This module serves as the inverter unit (INU) or phase control module of the ACS6000, responsible for precise motor speed and torque control. It supports direct torque control (DTC) technology, achieving millisecond-level response and low-energy operation.

Modular Design: The ACS6000 utilizes a modular architecture. The 3BHB906001446 module can correspond to inverter modules of specific power levels (e.g., 3/5/7/9/11 MVA), supporting single- or multi-motor drive configurations and adapting to motors from 3 to 27 MW at a voltage level of 3.3 kV.

Key Technologies: It integrates IGCT power semiconductors, active rectifier units (ARUs), and capacitor banks (CBUs) to achieve efficient energy distribution via a common DC busbar, supporting redundancy and fault isolation.

Technical Specifications and Parameters

Power Range: Covers 3 to 27 MVA, supports synchronous and asynchronous motor drives, and is suitable for industrial applications (such as rolling mills, ship propulsion, and mining machinery). Control Features: High-precision speed/torque control based on DTC technology supports dynamic process optimization (such as rapid start/stop and load-surge response).

Physical Features: Modular cabinet design supports both water and air cooling, and electromagnetic compatibility (EMC) and safety protection meet international standards (such as CE certification).

Maintenance and Troubleshooting

Daily Maintenance: Regularly check the IGCT and diode status (measure gate voltage with a multimeter and observe LED indicators), and use DriveWindow software to analyze fault logger data.

Troubleshooting:

Common faults: Overcurrent, overvoltage, IGCT damage, etc. Use the fault code to locate the problem module (such as the ARU/INU) and repair it by replacing the phase module or power components.

Critical faults: For example, if the DC busbar is short-circuited, disconnect the power supply and use specialized tools to check the power semiconductor status, following safe operating procedures.

Spare Parts Management: ABB provides genuine spare parts (such as the 3BHB011219R0001 capacitor and the 3BHB018008R0101 phase module). Purchases must be made through official channels to ensure compatibility.

Application Scenarios and Advantages

Industrial Applications: Widely used in the steel, oil and gas, power generation, and marine industries, it supports efficient driving of high-power motors, improving production efficiency and reducing energy consumption.

System Advantages: The modular design reduces maintenance costs, supports remote monitoring and predictive maintenance, and provides technical support through ABB’s global service network.

https://www.weikunfadacai1.com/product/3bhb906001446-acs6000-medium-voltage-ac-drive-system-phase-controller-3bhb906001446-abb/