Description

Many products are not yet available. Please contact us for more information.

If the product model number differs from the displayed image, the model number will prevail.

Please contact us for specific product images, and we will arrange for a photo confirmation at the warehouse.

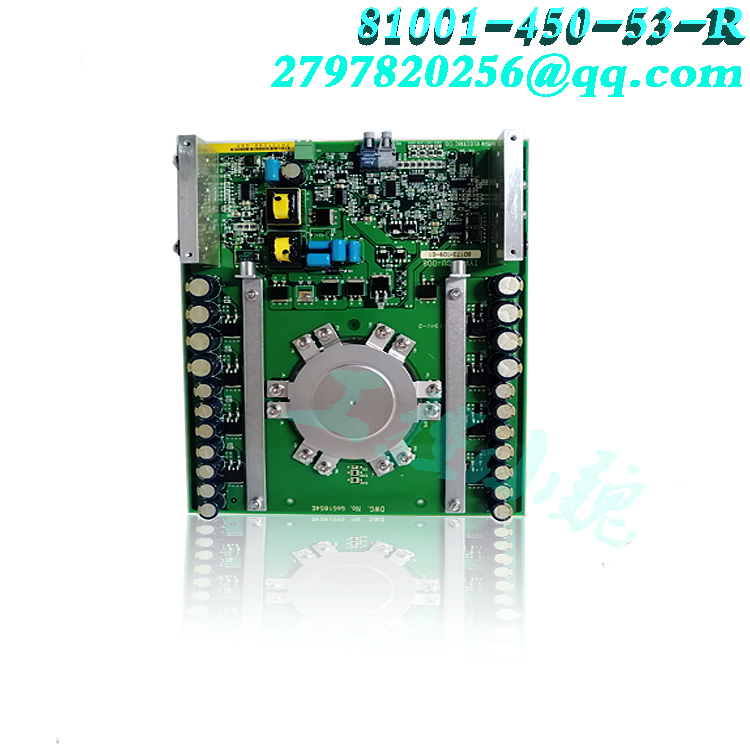

81001-450-53-R Other Names:

Control Unit81001-450-53-R

81001-450-53-R Analog Unit

Input/Output Unit 81001-450-53-R

We have 76 shared warehouses worldwide, so it may sometimes take several hours to accurately return your order. Please understand. We will, of course, respond to your inquiries as soon as possible.

Technical Parameters and Specifications

High-Voltage Compatibility: Designed for 800V DC bus voltage, this product meets interlayer withstand voltage requirements of 1.3kV or higher (safety factor 3x). High-TG FR4 or high-performance laminates such as Isola and Rogers are used to ensure dielectric strength (20-40kV/mm) and dielectric loss factor (tanδ≈0.015) meet requirements.

Creepage Distance and Clearance: According to IPC-2221, 800VDC requires ≥3.2mm clearance. Increase creepage distance by slotting, conformal coating, or insulating adhesive to prevent electric field concentration.

Impedance and Signal Integrity: High-frequency circuit boards can control impedance (e.g., 50Ω microstrip lines), with line width/spacing ≥4mil/4mil to reduce signal loss and ensure power conversion efficiency (e.g., energy consumption reduced by [X]% and efficiency increased by [X]%).

Electrical Characteristics:

The power management chip is the core, monitoring the rectified voltage (e.g., 310V), transformer output, and electrolytic capacitor status.

Compatibility: Compatible with Allen-Bradley PLC systems (e.g., 1756 and 1747 series), ABB robot spare parts, Siemens S5 series, and other industrial control equipment.

Application Scenarios and Certification

Industrial Scenarios: Suitable for factory production lines, power modules, motor controllers, etc. For example, after adoption in a large factory, energy consumption was reduced by [X]% and production efficiency increased by [X]%, demonstrating high performance and stability.

Safety Certifications: Complies with UL certification (e.g., UL94 V-0) and IPC-2221 standards, and has passed voltage withstand testing (1200V DC/1 minute, leakage current <1mA), ensuring stable operation in high-temperature, high-humidity, and electromagnetic interference environments.

Industrial:

Motor Control: Speed and power regulation for pumps, fans, compressors, and other equipment, achieving energy conservation and automation.

Power Transmission: Generator output frequency regulation and substation distribution system optimization.

Resource Extraction: Precision control of drilling rigs and pumping equipment in the oil, gas, and mining industries.

Transportation and Infrastructure:

Railway (subway, tram) traction systems, regulating the speed and acceleration of electric vehicles..jpg)

Aerospace: Aircraft/spacecraft power systems and servo control.

Other Applications:

Manufacturing: Equipment control in machining, injection molding, and food processing.

Construction and Energy: Practical assessment systems for high-voltage electrical work and photovoltaic/wind power training systems.

Maintenance Guide

Basic Repair Steps:

Appearance Inspection: Check for bulging, burnt, or cracked components (such as electrolytic capacitors and resistors), and replace damaged components first.

Electrical Inspection:

Use a multimeter to measure the rectified voltage (normally 310V), the output voltage of the power management chip, and the transformer status.

Check for blown fuses (which may indicate a short circuit) and troubleshoot problems in the primary circuit (rectifier bridge, fuse) and downstream circuitry.

Special Component Handling:

Electrolytic capacitors: Replace if aged or leaking. Pay attention to discharging high-voltage capacitors.

Solder Joint Inspection: Weak/cold solder joints require resoldering. Use a magnifying glass or thermal imaging camera to locate hot spots..jpg)

Optocouplers and relays: Check isolation and feedback functions to ensure there are no poor contact or oxidation.

Safety Precautions:

Wear insulating gear when working with high-voltage circuits to avoid the risk of electric shock.

Static Electrostatic Discharge (ESD) Protection: Use anti-static protection during winter operation to avoid damaging components by touching live motherboards.

Post-repair testing: Before applying power, verify that there are no short circuits. Gradually increase the voltage to test for functional recovery.

All products on this website are special products, and market prices are constantly fluctuating.

Please refer to customer service for specific quotes. Since these products are new, prices are not accurate.

Please confirm model, product, price, and other details with customer service before placing an order. This website is used.

New products are available for sale. Please contact customer service for details.

Related product recommendations:

1394-SJT22-T-RL

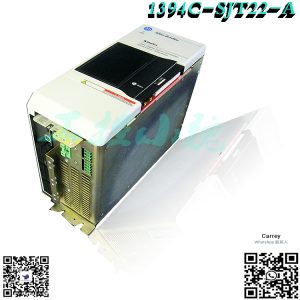

1394C-SJT22-A

1394-SJT22T

1394-SJT22-C-RL

1394C-SJT10-C-RL

1394-SJT10-A /A

1394C-SJT05-T /C

1394-SJT05-A

1394C-SJT05-L-RL

1394C-SJT05-A /C

81003-438-51-R

80190-220-01-R

81001-340-71-R

More……

Reviews

There are no reviews yet.