Description

Many products are not yet on the shelves. Please contact us for more products.

If the product model is inconsistent with the display picture, the model shall prevail. Please contact us for specific product pictures, and we will arrange to take photos in the warehouse for confirmation.

We have 76 shared warehouses around the world, so sometimes it may take several hours to return to you accurately, please understand. Of course, we will respond to your concerns as soon as possible.

GBU72 3BHE055094R0002 3BHB030310R0001 PCS6000 Other names:

Grid breaker unit PCS6000 GBU72 3BHE055094R0002 3BHB030310R0001

GBU72 3BHE055094R0002 3BHB030310R0001 PCS6000 grid breaker unit

Inverter PCS6000 GBU72 3BHE055094R0002 3BHB030310R0001

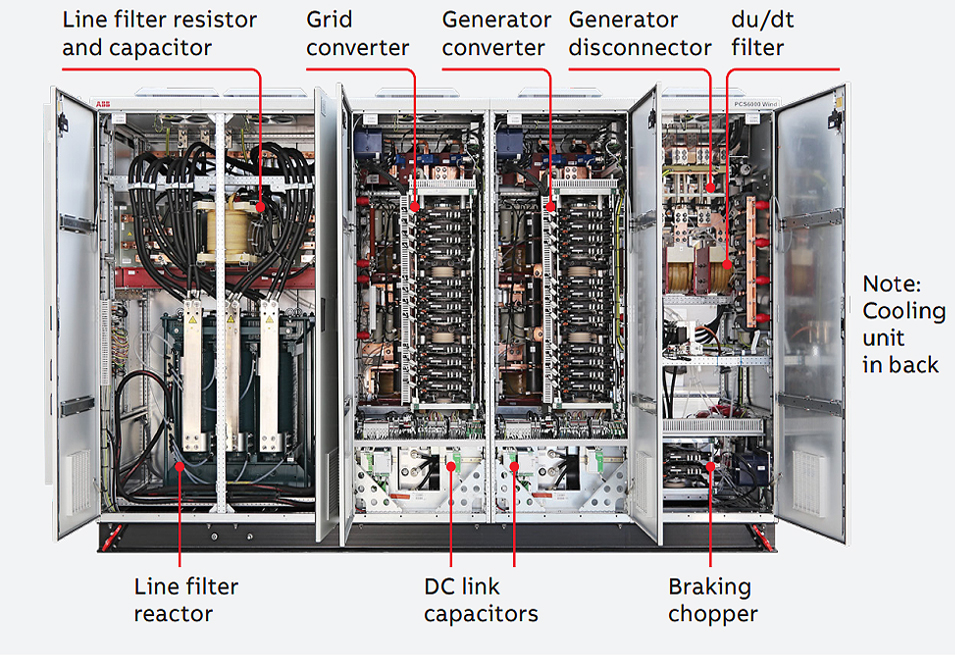

ABB PCS6000 full power converter GBU72 3BHE055094R0002 3BHB030310R0001 is a high-performance power electronic device designed by ABB Group for renewable energy power generation (such as wind power generation, photovoltaic power generation) and energy storage systems, with high efficiency, high reliability and intelligent control capabilities.

Product Overview

Definition and Positioning

PCS6000: Full power converter (Power Conversion System), used to convert direct current generated by renewable energy (such as wind power, photovoltaic power generation) into alternating current, or to achieve two-way energy exchange between energy storage systems and power grids. Applicable to megawatt-level high-power scenarios, emphasizing high reliability, high efficiency and grid compatibility.

Core application scenarios

Wind power generation: connect wind turbines to the grid to achieve maximum power point tracking (MPPT) and low voltage ride-through (LVRT).

Photovoltaic power generation: adapt to large photovoltaic power stations, support centralized or string inverter solutions.

Energy storage system: as the core equipment of the battery energy storage system (BESS), it realizes charging and discharging control and grid peak and frequency regulation.

Microgrid: coordinates the energy management of distributed power sources and loads in off-grid or grid-connected mode.

Onshore/offshore wind farms: as the interface between wind turbines and the grid, improve wind energy utilization and grid stability.

Photovoltaic power station: used for centralized photovoltaic inverters to achieve maximum power point tracking (MPPT) and grid-connected control.

Energy storage system: combined with battery energy storage, it realizes peak shaving, frequency regulation, backup power supply and other functions to enhance grid flexibility.

Microgrid and distributed energy: support multi-energy complementarity (such as wind, solar and storage integration) to achieve autonomous operation of local power grids.

Technical specifications and performance parameters

Power level

Typical power range: 1MW-10MW

Support parallel expansion to meet the needs of large power stations.

Electrical parameters

Input side (DC):

Voltage range: 600V-1500V DC (adapt to different photovoltaic modules or wind power converter output).

Maximum input current: depends on the power level (such as 5MW models may support ≥3000A).

Output side (AC):

Voltage level: medium voltage (10kV/35kV) or low voltage (400V), matching grid access requirements.

Frequency: 50Hz/60Hz adaptive, supporting global grid standards.

Power factor: ≥0.99 (adjustable), meeting reactive power compensation requirements.

Total harmonic distortion (THD): <3%, in line with IEEE 519 standard.

Efficiency and reliability

Peak efficiency: ≥98.5% (European efficiency standard), reducing energy loss.

MTBF (mean time between failures): >100,000 hours, adapting to harsh environments (such as deserts and coastal areas).

Protection level****: IP54/IP65, dustproof and waterproof design, supporting outdoor installation.

Cooling method: liquid cooling or air cooling optional, adapting to high temperature/high altitude areas.

Core functions and technical features

Intelligent control algorithm

Maximum power point tracking (MPPT): dynamically adjust the working point to improve power generation efficiency (wind power/photovoltaic scenarios).

Low voltage ride-through (LVRT): keep connected to the grid when the grid fails to avoid power fluctuations caused by disconnection.

Power regulation: support active/reactive independent control, participate in grid frequency and voltage regulation services.

Black start capability: When the power grid is completely out of power, the energy storage system is used to restore power supply (microgrid application).

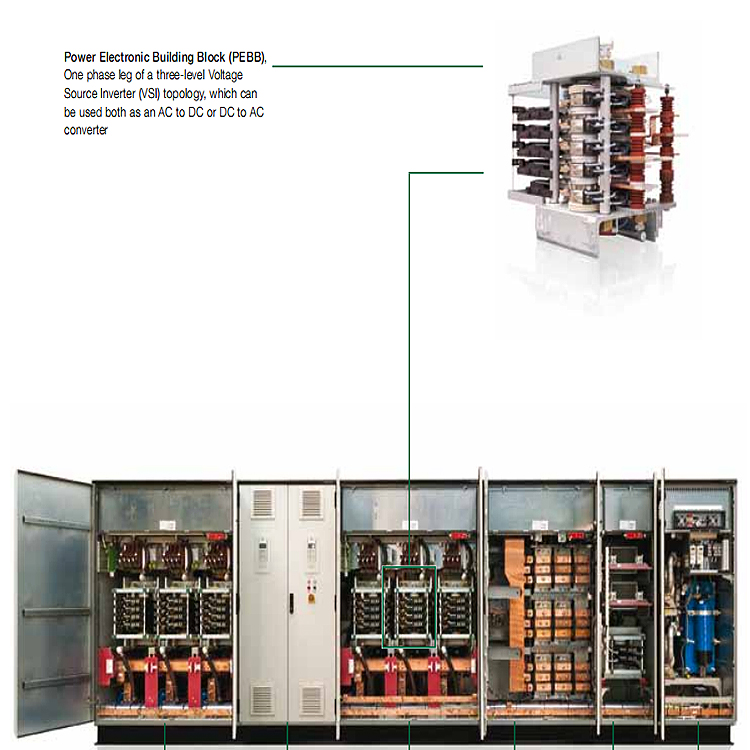

Modular design

Power module: IGBT/SiC devices are used, hot-swappable, and easy to maintain and expand.

Control unit: Distributed architecture and redundant design improve system availability.

Communication interface: Support IEC 61850, Modbus TCP, DNP3 and other protocols, integrated into SCADA or energy management system (EMS).

Power quality optimization: Improve grid stability and reduce harmonic pollution through active/reactive power control.

Grid-connected control: Support low voltage ride-through (LVRT), high voltage ride-through (HVRT) and other grid fault response capabilities.

Bidirectional energy flow: Applicable to energy storage systems to achieve flexible switching of charging/discharging modes.

Environmental adaptability: Designed to meet stringent industrial standards (such as IP54 protection level, vibration/shock resistance).

Full power conversion

Convert the AC power output by the generator (such as a wind turbine) into DC power, and then invert it into AC power that meets the requirements of the grid to achieve flexible connection with the grid.

Supports bidirectional power flow, suitable for grid-connected and off-grid modes.

Power quality control

Power factor correction and harmonic suppression are achieved through advanced control algorithms (such as vector control and direct torque control) to ensure that the output power meets grid standards (such as IEEE 1547, GB/T 19964).

Fault ride-through capability

With low voltage ride-through (LVRT) and high voltage ride-through (HVRT) functions, it maintains grid-connected operation when the grid voltage fluctuates and avoids disconnection.

Reactive power support

Dynamically adjust reactive power to improve grid stability, especially in weak grid environments.

Grid adaptability

Wide voltage/frequency range: adapt to grid fluctuations (such as voltage deviation ±15%, frequency deviation ±2Hz).

Harmonic suppression: built-in filter to reduce pollution to the grid.

Anti-islanding protection: Quickly disconnect after detecting power failure of the power grid to ensure personnel safety.

Installation and commissioning

Installation requirements

Mechanical installation:

Solid foundation, earthquake-resistant design (especially suitable for wind power scenarios).

The heat dissipation channel is unobstructed to avoid the risk of leakage in the liquid cooling system.

Electrical wiring:

DC side: positive and negative polarity are correct, and the insulation monitoring device (IMD) is connected.

AC side: grounding resistance meets the standard (such as ≤4Ω).

Debugging process

Function test:

Simulate power grid fault and verify LVRT function.

Check the power factor adjustment range (such as 0.8 leading to 0.8 lagging).

Performance optimization:

Adjust MPPT parameters to adapt to different light/wind speed conditions.

Optimize harmonic filter parameters to reduce THD.

Typical application cases

Offshore wind power projects

Scenario: A 500MW offshore wind farm

Solution: PCS6000 converter GBU72 3BHE055094R0002 3BHB030310R0001 is used to support 10MW wind turbines connected to the grid, with IP67 protection level and salt spray corrosion resistance.

Large photovoltaic power station

Scenario: 1GW photovoltaic base in Northwest China

Solution: PCS6000 centralized inverter, with 1500V DC system, reduces line loss and improves efficiency.

Grid-side energy storage

Scenario: Peak and frequency regulation auxiliary services

Solution: PCS6000 bidirectional converter + lithium battery energy storage system, response time <100ms, supports millisecond-level power regulation.

Maintenance and troubleshooting

Daily maintenance

Cleaning inspection: Clean the cooling fan/filter regularly to prevent dust accumulation.

Tightening inspection: Check whether the power module terminals are loose.

Software upgrade: Update the control algorithm through ABB special tools (such as PCM600).

Common faults and solutions

Fault code E01: DC overvoltage

Reason: PV module output is too high or brake resistor fails.

Solution: Check the number of modules in series and replace the brake resistor.

Fault code E05: AC side underfrequency

Reason: Low grid frequency or converter phase-locked loop (PLL) failure.

Solution: Verify grid frequency, restart converter and observe PLL status.

ABB PCS6000 full power converter GBU72 3BHE055094R0002 3BHB030310R0001 is the core equipment for renewable energy grid connection, characterized by high efficiency, high reliability and intelligent control. When selecting, focus on power/voltage matching, environmental adaptability and grid compatibility, and ensure long-term stable operation through regular maintenance.

All products on this website are special products, and the market price has been fluctuating.

The specific quotation is subject to the customer service. Because the product is a new product, the price is not real.

Please confirm the model and product, price and other detailed information with the customer service before placing an order. The website has been used.

New ones are on sale, please contact customer service for communication.

Related product recommendations:

S-093H 3BHB030478R0009

3BHB009884R0021 S-073N

3BHB009885R0052 S-097H

3BHB009885R0013 S-093M

ABB S-093H 3BHB030478R0309

ABB S-093S 3BHB030475R0009

S-093S 3BHB030475R0009

S-073N 3BHB009884R5211

S-073N 3BHB009884R0021 35SHY3545L0014

S-053M 3BHB012897R0003

S-073N 3BHB009884R0021 35SHY3545L0014

S-073N ABB 3BHB009884R0021

S-097H 3BHB009885R0052

S-093H 3BHB030478R0309

ABB 5SHY3545L0014 3BHB020720R0002

ABB 5SHY4045L0003

5SHY4045L0003 3BHE019719R0101

5SHY4045L0003 3BHB021400 3BHE019719R0101

5SHY3545L0005 336A4954ARP2

KUC321AE HIEE300698R1

KUC711AE 3BHB004661R0001

KUC720AE 3BHB000652R0001

GFD233A101 3BHE022294R0101

GFD563A102 3BHE046836R0102

GF D563 3BHE046836R010

3BHE017628R0002 PPD115A02

PPD517A3011 3BHE041576R3011

PCD232A 3BHE022293R0101

PCD237A101 3BHE028915R0101

PCD230A 3BHE022291R0101

PCD231B 3HHE025541R0101

PCD235C101 3BHE057901R0101

More……

admin –

Energy storage system: as the core equipment of the battery energy storage system (BESS), it realizes charging and discharging control and grid peak and frequency regulation.

Microgrid: coordinates the energy management of distributed power sources and loads in off-grid or grid-connected mode.

Onshore/offshore wind farms: as the interface between wind turbines and the grid, improve wind energy utilization and grid stability.

Photovoltaic power station: used for centralized photovoltaic inverters to achieve maximum power point tracking (MPPT) and grid-connected control.

Energy storage system: combined with battery energy storage, it realizes peak shaving, frequency regulation, backup power supply and other functions to enhance grid flexibility.

Microgrid and distributed energy: support multi-energy complementarity (such as wind, solar and storage integration) to achieve autonomous operation of local power grids.

https://www.weikunfadacai1.com/product/abb-pcs6000-full-power-converter-gbu72-3bhe055094r0002-3bhb030310r0001-2/

Ann –

Product positioning and core functions

GBU72 3BHE055094R0002

Role: The core control unit of the PCS6000 system, responsible for circuit breaker control, grid-side synchronization, communication coordination, and state management.

Technical characteristics:

Integrated IGCT (Integrated Gate Commutated Thyristor) technology supports high-voltage and high-power scenarios (rated voltage of 72.5kV, rated current of 3150A).

It possesses rapid response capability (response time <1μs), enabling real-time monitoring of grid parameters (current, voltage, frequency) and achieving fault isolation and system protection.

Supports multiple communication protocols (such as MODBUS), and seamlessly interfaces with modules like PMI, PEC, and HMI.

Application scenario:

Wind power converter system: Ensures stable operation of IGCT under grid fluctuations and enhances power generation efficiency.

Industrial drive: Control high-power motors (such as metallurgical and mining equipment) to achieve smooth start-stop and energy-saving optimization.

Rail transit: used in subway traction converters to reduce energy consumption and failure rate.

3BHB030310R0001

Role: As the driving core of PCS6000, the IGCT power module performs high-voltage switch control.

Technical characteristics:

Rated voltage: 4500V, rated current: 4000A (dependent on cooling conditions), supports high-frequency switching (8.3ms half-wave pulse current of 1300A).

Integrated overcurrent, overvoltage, and undervoltage protection mechanisms ensure the reliability of the module under extreme operating conditions.

It is encapsulated with epoxy resin for moisture and dust resistance, making it suitable for harsh environments (operating temperature range: -40℃ to +125℃).

Application Scenario:

High-voltage frequency converter system (such as ACS6000): controls the power supply connection and disconnection, and protects the stable operation of the frequency converter.

Renewable energy inverter: DC rectification module for photovoltaic/wind power systems, capable of withstanding high surge currents.

https://www.weikunfadacai1.com/product/

Ann –

Technical comparison and synergy

Parameter GBU72 3BHE055094R0002 3BHB030310R0001

Functional positioning control and protection central power execution unit

Core technologies include intelligent control algorithms, high-speed communication IGCT power semiconductors, and efficient heat dissipation design

Rated voltage/current 72.5kV/3150A 4500V/4000A

Response speed<1 μ s (fault detection) 8.3ms (half wave pulse)

Typical applications include wind power, industrial drives, high-voltage inverters for rail transit, and renewable energy inverters

Collaborative Logic:

GBU72 acts as the "brain" and sends control instructions (such as closing/opening) to 3BHB030310R0001 by monitoring grid parameters (such as voltage and frequency) in real-time. 3BHB030310R0001 acts as a "muscle" to perform high-voltage switch actions and provide feedback on status data (such as temperature and current) to GBU72, forming a closed-loop control to ensure safe and efficient operation of the system.

Performance advantages and industry value

Efficiency and reliability

The PCS6000 adopts a full power converter topology, decouples the mechanical transmission chain from the power grid, reduces turbine stress, and extends equipment life.

The modular design of GBU72 and 3BHB030310R0001 supports rapid maintenance and reduces downtime (such as remote parameter configuration and hot plug functionality).

Economy and Sustainability

High voltage midstream design reduces current loss, improves power generation efficiency (approximately 98% rated point efficiency), and lowers the cost per kilowatt hour.

The design without fuses avoids on-site replacement, supports remote restart, and reduces operation and maintenance costs.

Grid adaptability

Comply with strict grid regulations (such as low voltage ride through and frequency regulation) to ensure the stability of wind farm grid connection.

Support parallel connection of multiple generators, suitable for large offshore wind farms (power range up to 15MW).

Selection suggestions and precautions

Scene matching

In the field of wind power, priority should be given to the combination of PCS6000+GBU72+3BHB030310R0001 to meet the high reliability requirements of offshore wind power.

Industrial drive: If you need to control high-power motors (such as rotary kilns in cement plants), you can use ACS6000 frequency converter integrated with 3BHB030310R0001 module.

Environmental adaptability

3BHB030310R0001 needs to ensure that the crimping pressure is in contact with the heat dissipation to avoid performance degradation caused by overheating.

GBU72 needs to be correctly connected to a 24VDC power supply and fiber optic interface to prevent electrostatic damage.

Cost and Maintenance

The initial investment of the PCS6000 system is relatively high, but the life cycle cost (LCC) is lower than traditional solutions, making it suitable for long-term operational projects.

It is recommended to conduct regular module health checks (such as insulation resistance testing and temperature monitoring) to prevent malfunctions in advance.