Description

Many products are not yet available. Please contact us for more information.

If the product model number differs from the displayed image, the model number will prevail. Please contact us for specific product images, and we will arrange for photos to be taken at the warehouse for verification.

We have 76 shared warehouses worldwide, so it may sometimes take several hours for us to accurately return your order. We apologize for this. Of course, we will respond to your inquiries as soon as possible.

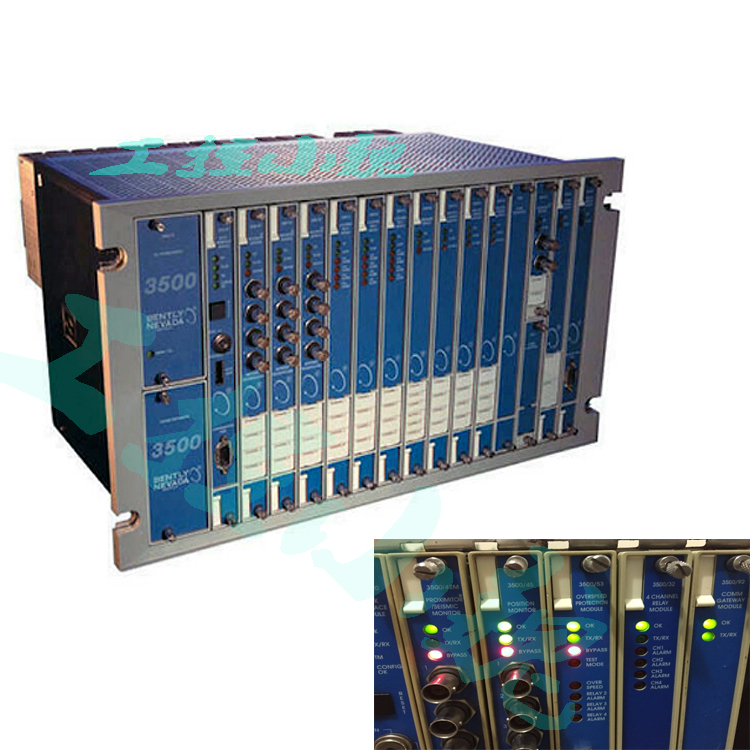

3500/45 176449-04 Other Names:

Position Monitor 3500/45 176449-04

3500/45 176449-04 Channel Position Monitoring Module

The Bently Nevada 3500/45 176449-04 Position Monitor is a four-channel position monitoring device from Bently Nevada and a core component of the 3500 Series Machinery Protection System. This product focuses on real-time monitoring of key parameters such as axial displacement, differential expansion, and case expansion of rotating machinery (such as turbines, compressors, and fans). It compares input signals from sensors such as eddy current sensors and LVDTs with user-programmable alarm thresholds, enabling online protection and condition monitoring of the machinery. Designed to comply with API 670 standards, it is widely used in demanding industries such as power generation, petrochemicals, metallurgy, and papermaking.

High-Precision Measurement

Provides high-precision shaft position monitoring with micron-level accuracy, suitable for critical equipment such as turbines and compressors.

Supports vibration monitoring, enabling simultaneous analysis of mechanical vibration data to assess equipment health.

Multi-Channel and Compatibility

A four-channel design accepts inputs from sensors such as eddy current sensors, LVDTs (DC/AC), and rotary potentiometers.

Modular Design: Compatible with other 3500 series modules (such as vibration and speed monitoring modules), supporting integrated system construction.

Real-Time Monitoring and Alarming

Real-time data acquisition and analysis, supporting instant alarms (such as for excessive axial displacement and abnormal differential expansion).

Users can set alarm thresholds through the 3500 Framework Configuration Software, which supports comprehensive alarm outputs for critical values.

High Reliability

Compliant with API 670 standards, it is suitable for continuous online monitoring in industrial environments.

Designed with an emphasis on durability, it is suitable for heavy industries such as power generation, chemical engineering, and metallurgy.

1. Hardware Configuration

Number of Channels: 4, with paired programming supporting different functions (e.g., channels 1-2 for axial displacement monitoring, channels 3-4 for shell expansion monitoring).

Input Type:

Sensors Supported: Eddy current sensors (25mm, 35mm, and 50mm extended ranges), DC/AC LVDTs, rotary potentiometers, and rotary position sensors (RPTs).

Signal Conditioning: Signal conditioning is performed at 25°C to ensure stability.

Output Interface:

LED Indicators: The front panel features OK, TX/RX, and bypass status indicators, providing real-time display of device operating status.

Relay Output: Supports alarm and danger signal outputs. Alarm logic (e.g., 2-out-of-1 or 3-out-of-2 mode) can be configured via the 3500 Rack Configuration Software.

Communication Protocol: Programmable via the 3500 Rack Configuration Software (e.g., 3500/01-01), supporting industrial protocols such as Modbus TCP/IP.

Operating Environment:

Operating Temperature: -20°C to +70°C (industrial-grade wide temperature design).

Protection Rating: While not specifically labeled with an IP rating, the device features corrosion-resistant and dust-proof design, making it suitable for harsh environments.

2. Features

Multi-Parameter Monitoring: Supports real-time monitoring of axial displacement, differential expansion (standard/non-standard single-slope, dual-slope, and complementary), case expansion, and valve position.

High-Precision Alarm: User-configurable alarm thresholds trigger protective actions via relay outputs, ensuring equipment safety.

Modular Design: Supports I/O module expansion (e.g., AC LVDT and rotary potentiometer modules) to accommodate diverse sensor needs.

Compatibility: Can be integrated into DCS platforms such as GE and Siemens, supports 3500 series rack configurations, and seamlessly integrates with TSI (Turbine Safety Monitoring System).

Application Scenarios

1. Power Industry

Turbine Monitoring: Real-time monitoring of axial displacement and differential expansion to prevent rotor-cylinder friction or bearing damage.

Generator Protection: Integration into DCS systems enables remote monitoring of vibration and position parameters and fault warnings.

2. Petrochemical Industry

Compressor Control: Monitors compressor bearing displacement to ensure the stability of high-pressure gas transportation.

Pipeline Transportation: Shell expansion monitoring prevents pipeline deformation caused by thermal expansion or pressure changes.

3. Metallurgy and Papermaking

Rolling Mill Bearing Monitoring: Real-time detection of bearing axial displacement extends equipment life.

Paper Machine Control: Monitors roller position to ensure paper production quality.

4. Other Industries

Rail Transportation: Monitors the condition of train traction motor bearings to prevent failures.

Wind Power Industry: Used for monitoring axial displacement of wind turbine gearboxes to improve equipment reliability.

Operation and Maintenance

1. Installation and Configuration

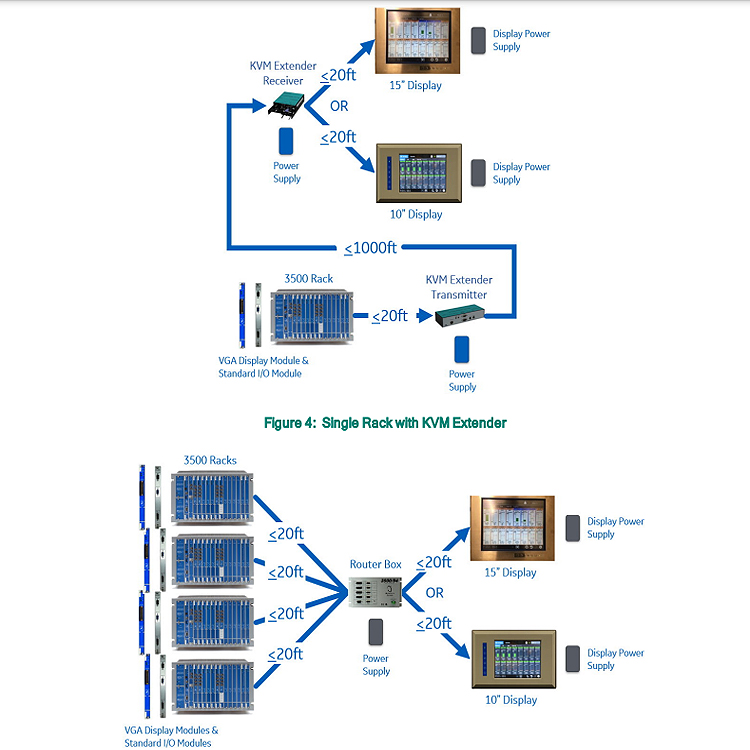

Physical Installation: Insert the sensor into the 3500 series rack, connect the sensor signal cable and power supply, and ensure all interfaces are secure.

Software Configuration:

Programming Tool: Use the 3500 rack configuration software (e.g., 3500/01-01) to program channels and set alarm thresholds.

Sensor Calibration: Adjust sensor sensitivity (e.g., axial displacement: 3.937 mV/mm or 7.874 mV/mm) through software.

Network Connection: Supports Modbus TCP/IP protocol, enabling integration into SCADA systems for remote monitoring.

2. Maintenance Recommendations

Periodic Calibration: Calibrate sensor sensitivity and alarm thresholds every six months to ensure accuracy.

Firmware Update: Download the latest firmware from the Bentley official website to improve system stability and functionality.

Troubleshooting: Use LED indicators and system logs to troubleshoot channel faults or sensor anomalies.

Backup and Recovery: Regularly back up programs and configurations to ensure rapid recovery.

Summary

The Bently Nevada 3500/45 176449-04 position monitor, with its four-channel monitoring, multi-sensor support, and high-precision alarms, has become a core device for condition monitoring of industrial rotating machinery. Its wide range of applications and flexible configuration options adapt to the complex needs of industries such as power generation, petrochemicals, and metallurgy, making it a key component for improving equipment reliability and production efficiency.

All products on this website are specialty items, and market prices fluctuate.

Please refer to customer service for specific quotes. Since these products are new, prices are not accurate.

Please confirm model, product, price, and other details with customer service before placing an order. This website is used.

New products are for sale. Please contact customer service for inquiries.

Related product recommendations:

BENTLY NEVADA 133388-01 AT LOW

3500/91 161204-01 Bently Nevada

Bently Nevada 3500/15 127610–01

BENTLY 1900/65A-00–00–02–00–01

BENTLY ASSY78462-01U

BENTLY 125680-01

Bently Nevada 3500/22M 288055-01

Bently Nevada 3500/22M 138607-01

More……

admin –

Input Type:

Sensors Supported: Eddy current sensors (25mm, 35mm, and 50mm extended ranges), DC/AC LVDTs, rotary potentiometers, and rotary position sensors (RPTs).

Signal Conditioning: Signal conditioning is performed at 25°C to ensure stability.

Output Interface:

LED Indicators: The front panel features OK, TX/RX, and bypass status indicators, providing real-time display of device operating status.

Relay Output: Supports alarm and danger signal outputs. Alarm logic (e.g., 2-out-of-1 or 3-out-of-2 mode) can be configured via the 3500 Rack Configuration Software.

Communication Protocol: Programmable via the 3500 Rack Configuration Software (e.g., 3500/01-01), supporting industrial protocols such as Modbus TCP/IP.

Operating Environment:

Operating Temperature: -20°C to +70°C (industrial-grade wide temperature design).

Protection Rating: While not specifically labeled with an IP rating, the device features corrosion-resistant and dust-proof design, making it suitable for harsh environments.