Description

Many products are not yet available. Please contact us for more information.

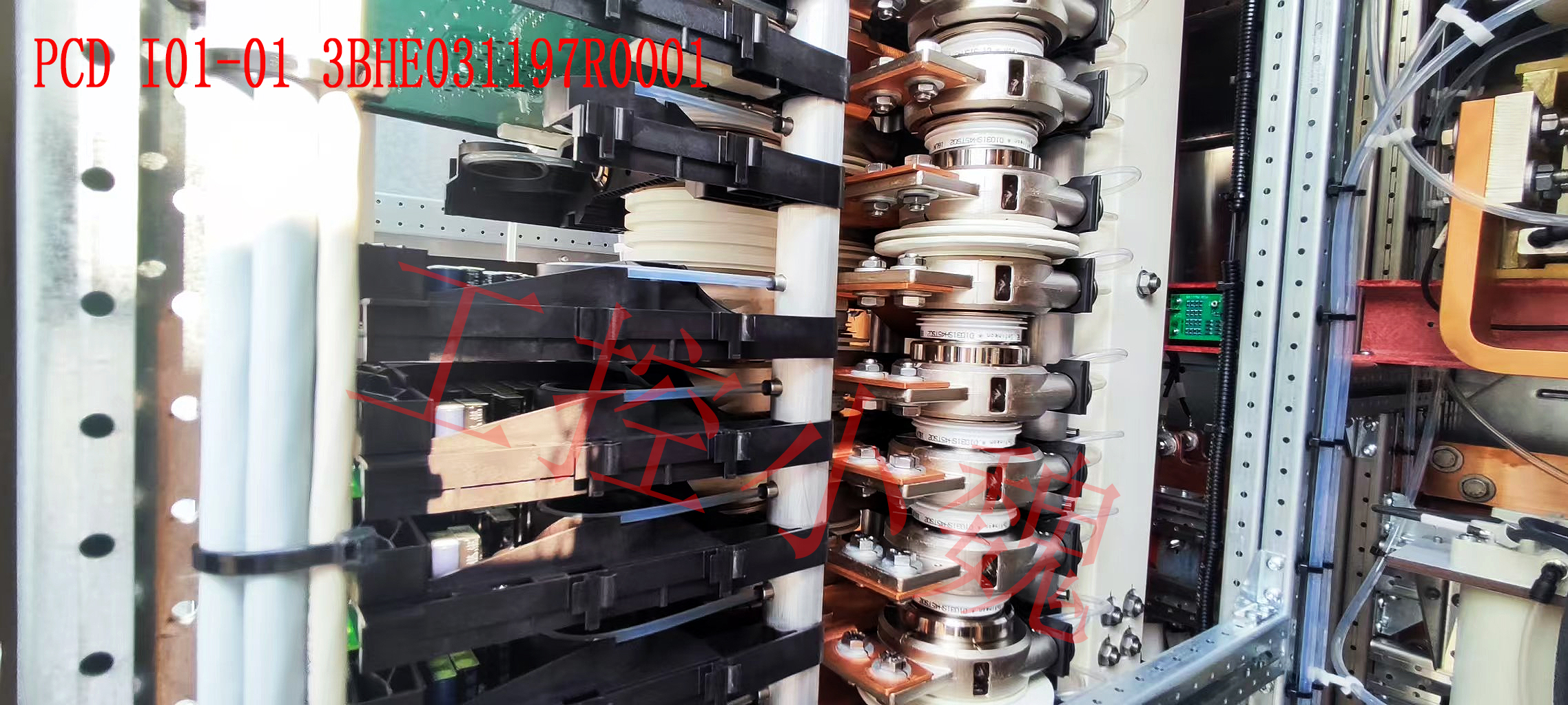

If the product model number differs from the displayed image, the model number will prevail. Please contact us for specific product images, and we will arrange to take photos at the warehouse for verification.

We have 76 shared warehouses worldwide, so it may sometimes take several hours for us to accurately return your order. We apologize for this. Of course, we will respond to your inquiries as soon as possible.

DLU75 3BHE046085R0100 Other Names:

PCS 6000 System Full Power Converter DLU75 3BHE046085R0100

DLU75 3BHE046085R0100 PCS 6000 System Medium Voltage Wind Turbine Converter

PCS 6000 System Medium Voltage Converter DLU75 3BHE046085R0100

ABB’s core grid circuit breaker unit DLU75 3BHE046085R0100 is designed specifically for large wind turbines, featuring a low component count, high availability, and minimized losses. The higher voltage rating of medium-voltage converters means lower currents in the power transmission system, making them easier to integrate into wind turbines. These converters can be designed for nacelle or tower installation, and their modular design allows for easy customization to meet customer needs. They also feature fault ride-through and grid compliance capabilities.

System Affiliation: The DLU75 3BHE046085R0100 is a core component of ABB’s PCS6000 medium-voltage power conversion system. As a grid breaker unit (GBU), it performs grid connection, power control, and system protection functions.

Core Functions:

Grid Control: Implements grid-side circuit breaker closing/opening, grid synchronization, power distribution, and fault isolation, ensuring safe system startup and shutdown, and continuous operation.

Circuit On/Off Control: Enables intelligent connection/disconnection between the grid and the drive system, supporting grid synchronization and power distribution.

Protection Mechanisms: Integrated overload, short-circuit, undervoltage, and overvoltage protection functions. Rapid shutdown (response time <1μs) and arc extinguishing technology limit short-circuit current peaks, improving grid stability.

Communication Coordination: Supports fiber optic, PROFIBUS DP, Modbus RTU, and other interfaces, enabling efficient communication with host controllers (such as the AC 800PEC), HMIs, and remote I/O modules.

Multiple Protection Mechanisms: Integrated overload, short-circuit, undervoltage, and overvoltage protection with a response time <1μs. Advanced arc extinguishing technology limits short-circuit current peaks, improving system stability.

Arc Extinguishment: Advanced arc extinguishing technology limits short-circuit current peaks, improving system stability.

Communication Interface: Communicates with a host controller (such as the AC 800PEC) via fiber optic cable and supports MODBUS or custom protocols, enabling remote monitoring and parameter configuration.

Expandability: By adding I/O modules (such as the GFD563A102) or communication interfaces (such as PROFIBUS DP and Modbus RTU), the system can adapt to project needs of varying sizes and support system upgrades and functional expansion.

Technical Parameters and Specifications

Electrical Performance:

Rated average rectified current 72A, maximum repetitive peak reverse voltage 800V, peak pulse current (8.3ms half-wave) 1300A.

Operating temperature range -40°C to +125°C, junction-to-case thermal resistance 0.45°C/W, insulation resistance ≥100MΩ (500VDC).

Supply voltage 24VDC ±15%, power consumption ≤12W, IP20 protection rating, and support for DIN rail or bolt-on mounting.

Control Features:

Equipped with a high-speed industrial-grade processor, supports IEC 61131-3 programming languages, and is compatible with ABB Control Builder software.

Redundant configuration supports hot switchover between active and standby controllers (switchover time <100ms), ensuring control logic continuity.

Application Scenarios and System Integration

Typical Applications:

Industrial Drives: Control of high-power motors in metallurgical rolling mills, mining machinery, and cement plants, compatible with ACS6000 medium-voltage inverters.

Renewable Energy: Synchronize power conversion with the grid in wind turbine converters and photovoltaic inverters, supporting low-voltage ride-through (LVRT).

Rail Transit: Control of subway traction converters and port cranes, ensuring high-reliability operation.

Infrastructure: Power grid protection systems and data center power management, enabling power outage protection and system interlocking.

System Collaboration:

Commonly works with ABB PM891/PM861 master control modules, IGCT modules (such as 3BHB030310R0001), 3BHE055094R0002 (power modules), and power modules (such as PS907W) to form a complete power conversion and control system.

Installation and Maintenance Key Points

Installation Requirements:

Installation must be performed in a control cabinet environment with a temperature range (-20°C to +70°C) and humidity range (<80% RH non-condensing). Ensure the backplane is compatible and the power module is properly connected.

Before installation, use an anti-static wrist strap to prevent static electricity from damaging the module’s internal components. An aluminum alloy heat sink is recommended to maintain the junction temperature below 100°C.

Maintenance Specifications:

Regularly check the control cabinet’s heat dissipation. Use ABB Control Builder software to monitor module status, log information, and communication status.

When replacing or upgrading a module, power must be disconnected. Current program and configuration parameters must be recorded. Firmware upgrades and system calibration are supported (recommended every two years).

Summary

The DLU75 3BHE046085R0100 , the core grid circuit breaker unit in the ABB PCS6000 system, is a core component in industrial automation and power control. Its high reliability, redundant configuration, and multi-protocol communication capabilities make it an ideal choice for high-power industrial drives, energy management, and critical process control.

All products on this website are special editions, and market prices are constantly fluctuating.

Please refer to customer service for specific quotes. Since these products are new, prices are not official.

Please confirm model, product, price, and other details with customer service before placing an order. This website is used.

New products are currently available for sale, so please contact customer service.

Related product recommendations:

ABB 5SHY3545L0014 3BHB020720R0002

ABB 5SHY4045L0003

5SHY4045L0003 3BHE019719R0101

5SHY4045L0003 3BHB021400 3BHE019719R0101

5SHY3545L0005 336A4954ARP2

KUC321AE HIEE300698R1

KUC711AE 3BHB004661R0001

KUC720AE 3BHB000652R0001

GFD233A101 3BHE022294R0101

GFD563A102 3BHE046836R0102

GF D563 3BHE046836R010

3BHE017628R0002 PPD115A02

PPD517A3011 3BHE041576R3011

PCD232A 3BHE022293R0101

PCD237A101 3BHE028915R0101

PCD230A 3BHE022291R0101

PCD231B 3HHE025541R0101

PCD235C101 3BHE057901R0101

More……

-300x300.jpg)

-1-300x300.jpg)

admin –

ABB DLU75 3BHE046085R0100 Core Grid Breaker Unit Comprehensive Analysis

Core Positioning and Technical Features

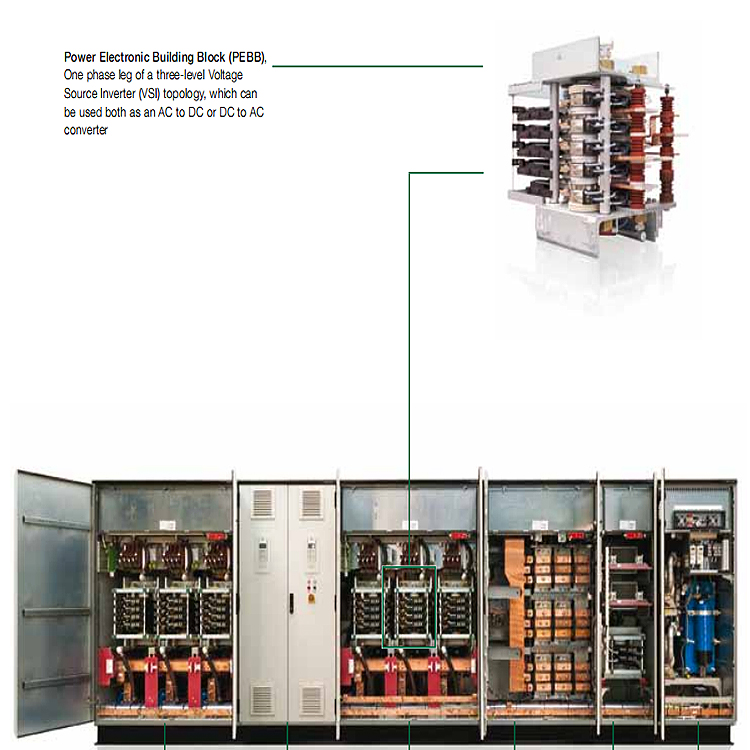

System Affiliation: Part of the ABB PCS6000 medium-voltage power conversion system, order number 3BHE046085R0100, this is the core module of the Grid Breaker Unit (GBU). It utilizes IGCT (Integrated Gate Commutated Thyristor) technology, supports four-quadrant bidirectional power flow, is suitable for 6kV/10kV medium- and high-voltage applications, and covers a power range of 4-120MVA.

Hardware Design:

Physical Parameters: Compact modular design, fits in a standard 19-inch rack, weighs approximately 1.5-2kg, has an IP20/IP54 protection rating, and operates in temperatures from -25°C to +70°C, making it suitable for harsh industrial environments.

Electrical Parameters: Input voltage 380V AC/220V DC, output voltage 0-400V AC or 5V-60V DC, output current 10A, power 100W, efficiency ≥92%, harmonic distortion (THD) <3% (compliant with IEEE 519 standard).

Interfaces and Communications: Compatible with PROFIBUS DP, Modbus TCP/IP, Ethernet/IP, and CANopen protocols, supporting OPC UA and IEC 61850 integration. Compatible with ABB 800xA and AC 800M control systems and third-party PLCs (such as Siemens and Omron).

Core Functions and Application Scenarios

Core Functions:

Grid Connection and Disconnection: Enables rapid connection and disconnection of the drive system to the grid, supporting fault isolation and system protection.

Power Flow Control: Regulates power transfer between the grid and equipment, optimizing reactive power compensation and dynamic voltage support.

System Protection: Built-in overvoltage/undervoltage, overcurrent, short-circuit, and overtemperature protection, supporting fault ride-through and rapid recovery.

Application Scenarios:

Power Industry: HVDC converter stations, STATCOMs (static synchronous compensators), grid dynamic reactive power compensation, and substation automation.

Industrial Automation: Metallurgical mill drives, mining crusher control, chemical pump/compressor energy-saving speed regulation, wind turbine pitch control systems, and rail transit traction motor control.

Special Applications: Marine propulsion systems, grid-connected inverters for new energy vehicles, arc furnace power factor optimization, and process optimization for municipal sewage treatment plants.

Technical Advantages and Innovations

Redundancy and Self-Diagnostics: Supports dual-module redundant configuration with active/standby switchover time ≤ 20ms; built-in fault code storage and remote diagnostic interface, compatible with SCADA systems.

Modular Expansion: Compatible with ABB S800 I/O modules and fiber-optic communication links, supports functional expansion up to 1024 I/O points, reducing integration costs.

Software Support: Compatible with ABB Control Builder M, Automation Builder, and CODESYS platforms, supports IEC 61131-3 programming standards, and automatically generates control code.

Certifications and Standards: Complies with international certifications such as CE and UL, meets industrial automation safety standards (such as IEC 61508), and has a built-in STO (Safe Torque Off) function.

Installation and Maintenance Recommendations

Installation: Follow DIN rail or 19-inch cabinet installation standards, ensure unobstructed heat dissipation (use a dual-mode air/water cooling system), and avoid electromagnetic interference sources (such as high-power motors). A separate overspeed protection device is required to comply with EMC standards (such as EN50082-2).

Maintenance Tips: Regularly check connector oxidation, capacitor aging, and cooling fan status; perform firmware upgrades every two years to optimize algorithms. Unauthorized modifications may void the warranty. Troubleshooting: LED indicators (such as RUN/ERR) can quickly locate problems. A solid red light indicates a hardware failure and requires contacting the supplier's technical support.

Compatibility Verification: Compatibility with ABB's PCS6000 backplane system, S800 I/O modules, and third-party devices must be confirmed to avoid configuration errors.

Latest Technology Updates and Application Cases

Technological Innovation: The 2025 version will support compatibility with the AC 800M series main modules (such as the PM851 and PM861). Integrated AI control technology enables autonomous operation. For example, in the petrochemical industry, AI automatically adjusts process parameters, reducing manual intervention and improving production efficiency and safety.

Application Case: In the DCS system of the Baoding Petrochemical Thermal Power Plant, the DLU75 reduces failure rates and extends service life by optimizing the cooling system design (such as air channels cooling power components). In small thermal power plants, the integration of new coating technology protects PCBs from dust and oil, ensuring reliable operation in harsh environments.