Description

Many products are not yet listed. Please contact us for more product information.

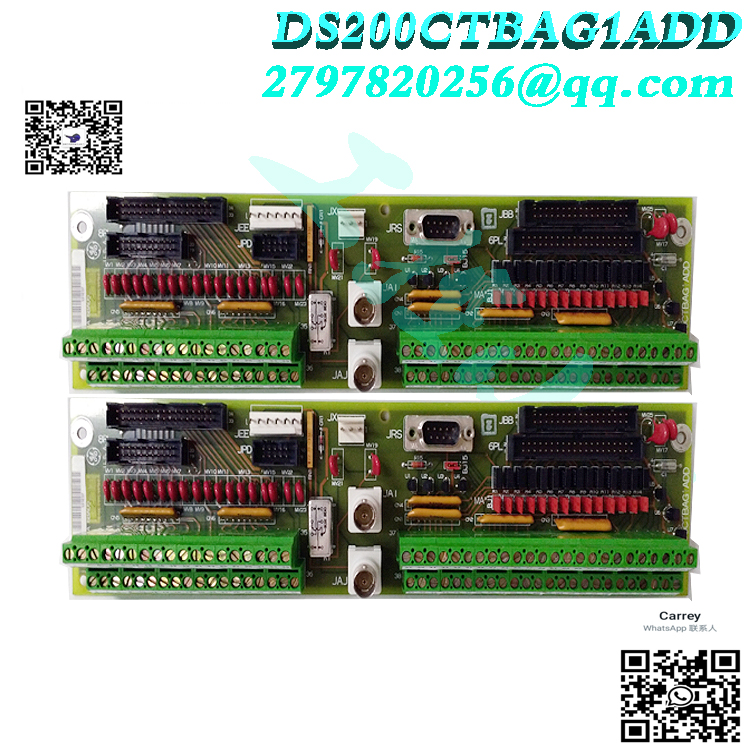

If the product model differs from the displayed image, the model number shall prevail. Please contact us for specific product images; we will arrange to take photos in our warehouse for confirmation.

We have 76 shared warehouses worldwide, so it may sometimes take several hours to accurately return the information to you. We apologize for the inconvenience. Of course, we will respond to your inquiries as soon as possible.

Other names for DS200TBQGG1ABB:

Digital Module DS200TBQGG1ABB

DS200TBQGG1ABB PCB Module

Analog Module DS200TBQGG1ABB

Technical Characteristics and Core Functions

Basic Attributes and Positioning

The DS200TBQGG1ABB is a GE DS200 series analog terminal module, specifically designed for the LM6000 gas turbine control system. It belongs to the RST extended analog terminal board and is compatible with the Mark V/VI system. The module measures 11.25 inches x 3 inches, features a modular design, supports rack mounting, and includes anti-static interfaces and redundant power supplies, meeting NEMA 4/4X protection standards.

Signal Processing and Interface Capabilities

Supports multi-channel analog signal input (e.g., 4-20mA, 0-10V), compatible with temperature, pressure, and vibration sensor signals from the LM6000 gas turbine.

Built-in high-precision conditioning circuitry, with a sampling rate of up to 64 cycles/Hz. Data is stored in non-volatile memory, supporting fault recording and event logging (0.5ms accuracy).

Communication interfaces support Modbus, Ethernet/IP, serial interfaces, and the ARCNET protocol, enabling seamless integration with DCS/PLC systems for remote monitoring and data transmission.

Signal Interface: Equipped with two terminal blocks (e.g., TB1/TB2), each containing 83-95 signal line terminals, supporting a total of 166-190 signal inputs; includes 34-pin/40-pin connectors and jumpers, compatible with multiple communication protocols (Modbus, Ethernet/IP, serial interface).

Redundancy and Diagnostics: Employs a TMR triple-modular redundancy architecture, supporting a “2oo3” voting mechanism; built-in self-diagnostic functions (CPU status monitoring, memory verification), providing real-time status feedback via LED indicators, and compatible with EnDM software for remote diagnostics.

Signal Processing and Compatibility:

Supports analog input (4-20mA, 0-10V), sampling rate up to 64 times/cycle, data storage in non-volatile memory, fault recording accuracy of 0.5ms.

Compatible with DCS/PLC system integration, supports IEC 61850, Modbus TCP, and other protocols, compatible with GE Mark V/VI control systems and third-party equipment (e.g., ABB, Siemens).

Redundancy and Reliability Design

The system adopts a TMR triple-modular redundancy architecture, achieving fault tolerance through a “2oo3” voting mechanism. In the event of a single module failure, it automatically switches to the redundant channel.

Built-in self-diagnostic functions (such as CPU status monitoring and memory verification) provide real-time status feedback via LED indicators and support remote diagnostics via EnDM software.

Operating temperature range: -20℃ to 70℃, humidity: 5% to 95% (non-condensing). It is EN55011 electromagnetic compatibility certified and adaptable to harsh environments such as high temperature, high humidity, and corrosive gases.

Application Scenarios and Industry Cases

Core Application Scenarios

LM6000 Gas Turbine Control: As the core analog terminal module of the LM6000 gas turbine control system, it is responsible for collecting key parameters such as temperature, pressure, and vibration, supporting full-process monitoring of gas turbine startup, operation, and shutdown.

Power and Energy Industry: Widely used in control systems of gas turbine power plants and combined cycle power plants, such as generator protection, motor control, and reactor temperature monitoring..jpg)

Industrial Automation: Used in petrochemical, metallurgical, and rail transportation industries for motor protection, traction power supply system monitoring, and reactor temperature/pressure monitoring.

Typical Cases

LM6000 Gas Turbine Project: In a large gas-fired power plant, the DS200TBQGG1ABB module serves as the analog signal acquisition unit for the LM6000 gas turbine control system, enabling real-time monitoring and fault early warning of the gas turbine’s operating status, ensuring the stable operation of the power generation equipment.

Rail Transit Traction Power Supply: In subway traction power supply systems, this module is used to acquire parameters such as temperature and current of the traction transformer, supporting remote monitoring and automatic protection functions.

LM6000PF Aero-derived Gas Turbine: Achieves real-time monitoring of natural gas calorific value and adjustment of combustion parameters through an analog terminal board, reducing NOx emissions to <25mg/m³, saving approximately 800,000 Nm³ of natural gas annually.

Swiss Federal Railways TWINDEXX Train: Acquires signals from the lateral compensation device, improving stability during curves.

Oil Refining Reactor: Temperature/pressure monitoring and safety interlock protection. Installation and Maintenance Specifications

Hardware Installation

Use DIN rail or panel mounting, conforming to NEMA 4/4X protection standards. Anti-static handling is required during installation; use anti-static wrist straps and tools to prevent electrostatic damage to integrated circuits.

Wiring must ensure secure terminal connections to avoid poor contact; in hazardous areas, intrinsically safe barriers or electrical insulation devices must be used to prevent electrical sparks from causing accidents.

After installation, a grounding test must be performed to ensure a single-point grounding design and avoid grounding loop interference.

Software Configuration

Programming is performed using TriStation 1131 or Enervista UR software, supporting ladder diagram (LD), function block diagram (FBD), and other languages.

Configuration includes channel parameters (range, alarm threshold), logic program, and communication protocol (e.g., IEC 61850). Online modification and hot deployment are supported to reduce downtime.

Maintenance Management

Regularly check LED status indicators and use diagnostic tools to analyze system logs and event records to troubleshoot potential faults..jpg)

Power switching and insulation tests are performed every 6 months to ensure the effectiveness of redundancy. Faulty modules support hot-swapping, automatically inheriting existing programs and data upon replacement.

During maintenance, high-voltage safety must be observed. Even after power is cut off, capacitors may still store voltage; wait 30 seconds before proceeding to avoid the risk of electric shock.

Compatibility and Expandability

System Integration

Works collaboratively with Mark V/VI series CPUs and I/O modules, supporting interface with platforms such as OPC UA and TriStation 1131 for multi-protocol communication and data fusion.

Supports customized processing (such as channel number adjustment and output type optimization). Power supply reliability is improved through redundant power modules (such as the 8006B), adapting to different process requirements.

Model Difference Explanation

The DS200TBQGG1ABB and DS200TBQGG1A belong to the same termination module series, but specific configurations may vary depending on customization requirements (such as channel number and communication protocol). It is recommended to contact GE or authorized dealers to verify technical parameters.

It is important to ensure compatibility with the LM6000 gas turbine control system, guaranteeing that the module’s signal type, range, and communication protocol match the host system.

Important Notes and Certification Information

Certifications and Standards

Complies with IEC 61508 SIL 3 safety certification, API 670 mechanical protection standard, and EN55011 electromagnetic compatibility certification, ensuring safe and reliable operation in industrial environments.

Summary: As the core analog terminal module of the GE LM6000 gas turbine control system, the DS200TBQGG1ABB demonstrates outstanding performance in power, petrochemical, and rail transportation sectors due to its high reliability, multi-channel signal processing, redundant design, and strong environmental adaptability. Users should consider specific application scenarios, follow installation and maintenance specifications, and verify model compatibility and certification information to achieve optimal performance and safety.

Please note that all products on this website are specialty items, and market prices are constantly fluctuating.

Please refer to customer service for a specific quote, as the price may not be accurate for new products.

Please confirm the model, product, price, and other details with customer service before placing an order. This website is currently in use.

New items are available for sale; please contact customer service for further information.

Related product recommendations:

IS200TTURH1CFD

IS200WEMAH1AEA

IS200AEPAH1AHD

IS200WETAH1AEC

IS200WREAS1ADB

IS200AEPAH1ACB

IS200AEPAH1AFD

IS200AEPCH1ABC

IS200BPPBH2BJD

IS200AEPCH1ABC

IS200TREAH2AED

IS200STCIH6AED

IS200SRTDH2ACB

IS200TVBAH2ACC

IS200TRLYH1BHH

IS200WEORG1A

IS200ESELH1A

IS200AEPGG1AAA

IS200TSVCH2AED

IS200EPMCH1

IS200JPDSG1A

IS220PPDAH1A

IS210JPDHG1A

IS220YSILS1B

IS200SCSAS1A

IS200WCSAS1A

IS220YSILS1A

IS200TCSAS1A

IS200WNPSS1A

IS41yJPDDG2A

IS41yJPDDG3A

IS40yJPDGH1A

IS411JPDHG1A

IS4210UCSBH4A

more……

-300x300.jpg)

-300x300.jpg)

Reviews

There are no reviews yet.