Description

Many products are not yet listed. Please contact us for more product information.

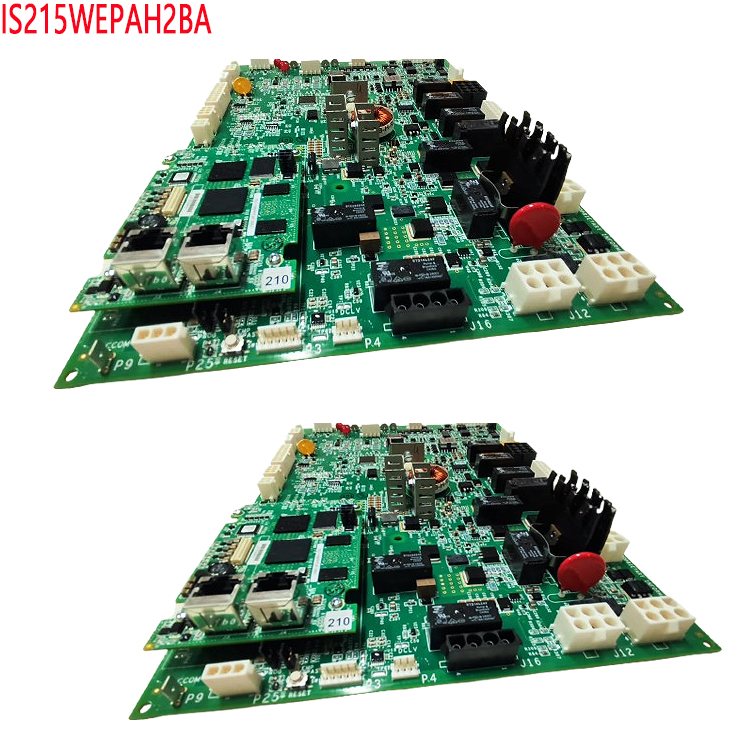

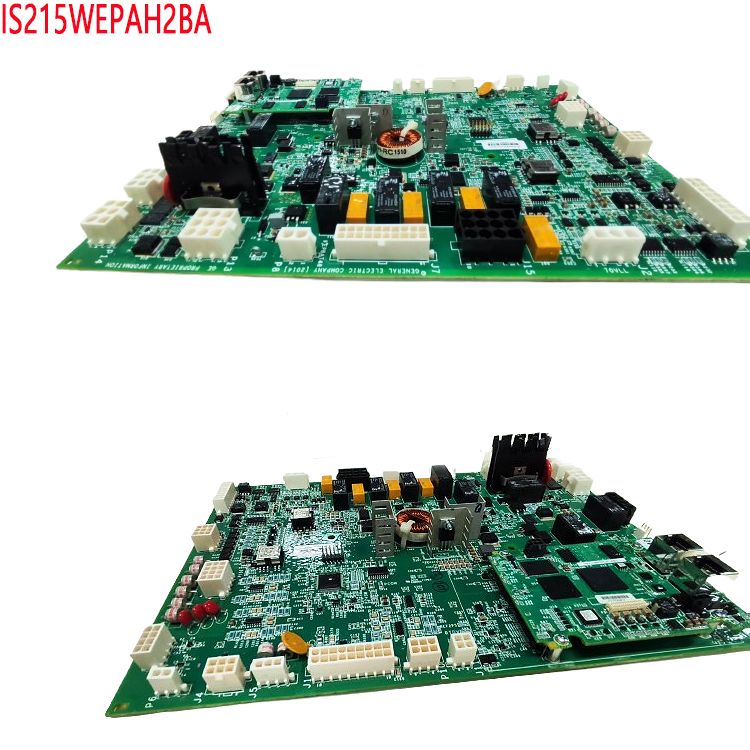

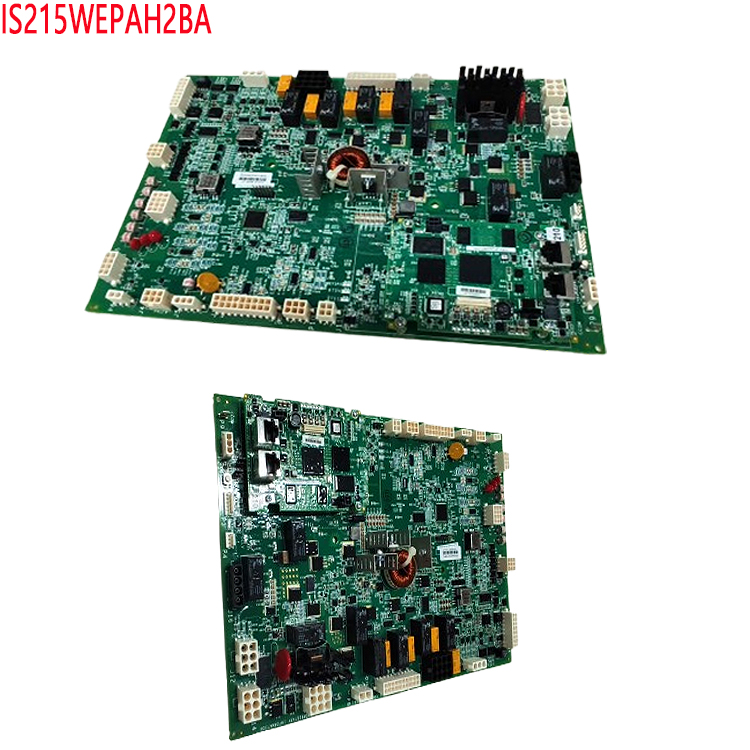

If the product model differs from the displayed image, the model number shall prevail. Please contact us for specific product images; we will arrange to take photos in our warehouse for confirmation.

We have 76 shared warehouses worldwide, so it may sometimes take several hours to accurately return the information to you. We apologize for any inconvenience. Of course, we will respond to your inquiries as soon as possible.

IS215WEPAH2BA Other Names:

High-performance processor board IS215WEPAH2BA

IS215WEPAH2BA WEPA circuit board

I/O packaged processor board IS215WEPAH2BA

This is a core component of industrial control systems, such as the EX2100 excitation control series or Mark VIe/VIeS turbine control systems. It is a key module for gas turbine control, power plant monitoring, and industrial automation. It supports various digital and analog signals and is suitable for industrial applications (such as power plants and automation control systems).

Functional Positioning: An I/O module connecting subsystems such as the compressor, combustion chamber, and turbine, enabling digital/analog signal transmission and communication, and supporting modular expansion.

Technical Characteristics

Hardware Structure:

Modular Design: Employs industrial-grade components (capacitors, resistors, diodes), supports digital/analog input/output, expandable I/O points, and compatible with PCI/PCI-X expansion slots.

Interface Configuration: Includes Ethernet, USB, and serial ports (RS-232/RS-485), compatible with 125VDC power supply, integrated metal oxide varistors for electromagnetic interference immunity, and conforms to aerospace standards such as MIL-STD-810 and DO-160.

Environmental Adaptability: Operating temperature -40°C to +70°C, storage temperature -55°C to +85°C, humidity tolerance 5%-95% (non-condensing), insulation resistance >1000MΩ, transient surge current tolerance 100A.

Multi-port design: Compatible with various I/O modules (such as temperature, pressure, and flow sensors), supporting flexible configuration.

Industrial-grade reliability: Employs high-temperature resistant and electromagnetic interference-resistant components, adaptable to the high-temperature and high-vibration environments of gas turbines.

Gas turbine control: Used for start-up, operation monitoring, and fault diagnosis of gas turbines such as the 9F class and LM2500, including:

Compressor inlet filtration system status monitoring

Real-time combustion chamber temperature/pressure control

Turbine exhaust temperature field uniformity analysis

Vibration and shaft health monitoring

Industrial automation: Automated control of power plants, petrochemical plants, and marine propulsion systems (such as ship propulsion main engines).

Modular structure: Facilitates rapid replacement and maintenance, reducing downtime.

Gas turbine integration:

System integration: Part of the GE Mark VI/EX2100 control system, directly involved in gas turbine control and status monitoring. For example:

Sensors and actuators connecting key components such as the compressor and turbine.

Monitor rotor vibration, temperature, pressure, and other parameters to ensure safe equipment operation.

Fault Correlation: If the gas turbine experiences “jamming” or abnormalities, it may involve signal transmission failures, configuration errors, or hardware damage in this module. Common fault types include:

Rotor-casing rubbing: Caused by insufficient clearance or abnormal vibration.

Oil film oscillation: A nonlinear dynamic problem in the bearing system, manifested as abnormal shaft trajectory.

Control system faults: Such as I/O module communication interruption, configuration errors, or hardware failure.

Performance Parameters:

Rated current 15A, control voltage DC 5V, switching frequency 200Hz, supports fast data processing and remote management via B/S architecture, compatible with Windows/Linux operating systems.

Application Scenarios

Industrial Control: In power, chemical, manufacturing, and rail transportation industries, it serves as a controller or I/O module, connecting sensors and actuators to achieve equipment monitoring and automated operation (e.g., gas turbine excitation systems, wind power generation control).

Energy Management: Used for real-time monitoring and dispatching of power plants, supporting dynamic fault detection, report export, and other functions, suitable for gas turbines, wind power generation, and other scenarios.

High Reliability Requirements: Suitable for harsh environments such as aerospace and oil drilling platforms, ensuring stable system operation.

Model Comparison and Extended Information

Comparison with IS200AEPAH1BKE: IS215WEPAH2BA has advantages in accuracy and redundancy options (such as triple redundancy configuration), suitable for high-precision measurement scenarios in oil and gas, chemical, and other industries.

Comparison with IS215WEPAH2BB: Both belong to the EX2100 series, but IS215WEPAH2BA performs better in interface expandability and anti-interference capabilities.

Common Problems and Solutions

Startup Failure:

Causes: Internal leakage in the speed ratio valve, impurities in the natural gas pipeline eroding the valve head, malfunction of the purge valve, abnormal communication between LCI and Mark V.

Solutions: Check valve sealing, clean pipeline impurities, and verify communication protocol parameters.

Ignition Abnormalities:

Symptoms: Weak ignition spark or inability to form a torch.

Solutions: Clean electrode carbon deposits, check fuel injector blockage, and adjust atomizing air pressure.

Uneven Exhaust Temperature:

Causes: Damaged combustion chamber flame tube, blocked blade cooling channels, uneven fuel distribution.

Solutions: Repair or replace the flame tube, clean the blade cooling channels, and optimize the fuel injection strategy.

Excessive Vibration:

Root Causes: Bearing/bearing wear, uneven cooling of low-pressure exhaust cylinders, and rotor dynamic balancing failure.

Solutions: Strengthen lubrication system maintenance, optimize cooling strategy, and perform rotor dynamic balancing correction.

Maintenance Recommendations:

Regular Inspections: Check I/O module connection status every 2000 hours of operation and calibrate sensor accuracy.

Troubleshooting: Use the diagnostic logs of the Mark VI system to locate module-level faults (such as port failure or communication interruption).

Spare Parts Management: It is recommended to stock the same model module (e.g., IS215WEPAH2BA) and compatible I/O modules to ensure rapid replacement.

Extended Information

GE Gas Turbine Model Rules: In PG9351FA, “PG” represents a containerized generator set, “9” is the series number, “F” indicates F-class (turbine inlet temperature approximately 1400℃), and “A” is the design version.

Industry Applications: GE gas turbines are widely used in power, petrochemical, and marine power industries. Their control systems (e.g., Mark VI) are known for their high reliability, but strict adherence to maintenance protocols is necessary to avoid unplanned downtime.

All products on this website are special products, and market prices are constantly fluctuating.

Please refer to customer service for a quote, as the product is new and the price is not yet accurate.

Please confirm the model, product, price, and other detailed information with customer service before placing an order. This website is currently in use.

New products are available for sale; please contact customer service for further information.

Recommended related products:

IS200TPROH1BCB

IS200JPDBG1A

IS200EDISG1A

IS200TCATH1ABA

IS220YAICS1A-L

IS200TRPGH1BDD

IS200TSVCH1ADC

IS200TTURH1CCC

IS200TSVCH1AED

IS200BPPBH2BJD

IS200AEPCH1ABC

IS200TREAH2AED

IS200STCIH6AED

IS200SRTDH2ACB

IS200TVBAH2ACC

IS200TRLYH1BHH

IS200WEORG1A

IS200ESELH1A

IS200AEPGG1AAA

IS200TSVCH2AED

IS200EPMCH1

IS200JPDSG1A

IS220PPDAH1A

IS210JPDHG1A

IS220YSILS1B

IS200SCSAS1A

IS200WCSAS1A

IS220YSILS1A

IS200TCSAS1A

IS200WNPSS1A

IS41yJPDDG2A\

IS41yJPDDG3A

IS40yJPDGH1A

IS411JPDHG1A

IS4210UCSBH4A

more……

-300x300.jpg)

Reviews

There are no reviews yet.