Description

Many products are not yet available. Please contact us for more information.

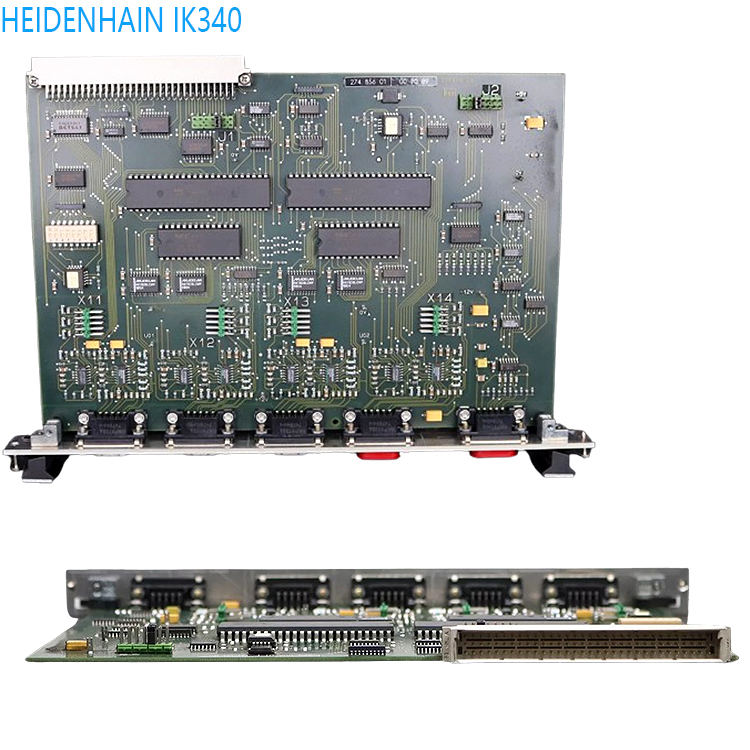

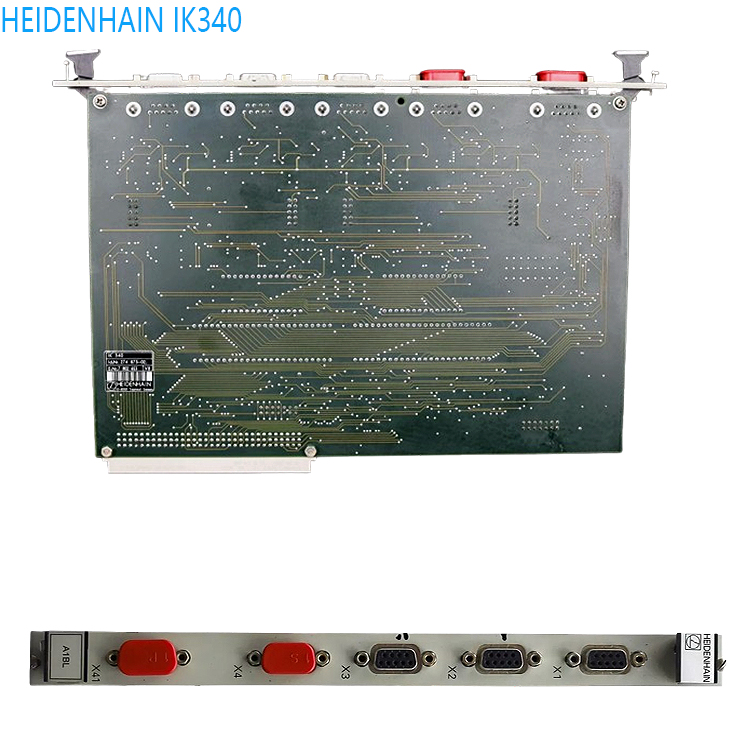

If the product model number differs from the displayed image, the model number will prevail. Please contact us for specific product images, and we will arrange for a photo confirmation at the warehouse.

We have 76 shared warehouses worldwide, so it may sometimes take several hours for us to accurately return your request. We apologize for this. Of course, we will respond to your inquiries as soon as possible.

The PCB card (printed circuit board card) plays a key role in core electronic control and data processing on ships. Its functions cover multiple aspects, including ship automation, safety monitoring, power management, communications, and environmental adaptation. Specifically, it can be divided into the following core functions:

Ship Automation Control System Core

Core Function: Serving as the “nerve center” for ship navigation, steering gear control, power system (such as main engine speed regulation and fuel supply), and propulsion coordination, it implements signal transmission and logic operations through precise circuit connections, ensuring efficient and stable system operation.

Example: In automated production lines, PCB cards connect temperature/pressure sensors and actuators to control the production process in real time. In power systems, they regulate fuel supply and exhaust systems, supporting automated control of unmanned engine rooms.

PLC and I/O Modules: As the hardware carrier of the programmable logic controller (PLC), the PCB card connects sensors (such as heading sensors and pressure sensors) and actuators (such as servos and valves) through I/O units, implementing logical operations, sequential control, and real-time feedback. For example, in an autopilot system, the PCB card integrates a PID control algorithm, adjusting the rudder angle proportional, integral, and differential parameters to ensure the ship accurately tracks the set course and resists wind and wave yaw.

Power System Collaboration: In the electrical control of the main engine, propeller, and auxiliary machinery, the PCB card is responsible for signal transmission and processing for fuel supply, exhaust gas regulation, speed synchronization, and other functions, ensuring efficient and stable operation of the power system.

Data Acquisition and Intelligent Processing

Sensor Signal Integration: Carries multiple sensor signals (such as GPS positioning, gyro attitude, and temperature/pressure monitoring) for navigation, power, and safety systems, enabling high-speed data transmission and real-time processing via high-speed buses (such as PCIe). For example, in ship navigation, the PCB card converts gyrocompass deviation signals into DC control commands to drive the servo to adjust the course.

Intelligent Algorithm Support: Supports algorithms such as closed-loop control, motion trajectory planning, and fault diagnosis to improve the accuracy and safety of ship operations. For example, the autopilot’s “weather adjustment” function dynamically adjusts the rudder angle response through low-gain/high-gain circuits to adapt to varying sea conditions.

Communication and Navigation Systems

Data Transmission: Supports real-time communication between the ship and the port, other vessels, and shore-based command centers. This includes integrating satellite communications, radar mapping (ARPA), and Global Positioning System (GPS) data to ensure navigation safety and collision avoidance.

Signal Processing: Processes signals from various sensors (such as gyroscopes and meteorological sensors) to ensure accurate navigation positioning and trajectory planning, maintaining stable communications, especially in complex sea conditions or when far from land.

Communication and Networking Capabilities

Ship-to-Shore/Inter-Ship Communications: Provides the circuit foundation for satellite communications, VHF, AIS, and other systems, ensuring real-time data exchange between the ship and the port, other vessels, and shore-based command centers. For example, RF modules supported by PCB boards enable broadband communications at sea, enabling remote monitoring and emergency response.

Networked Control: Supports networking of multiple systems to form a distributed control system, enabling centralized management and remote monitoring of all shipboard equipment, improving operational efficiency.

Safety and Emergency Systems

Safety Monitoring: In systems such as fire alarm, flood detection, and shipwide emergency shutdown (ESD), PCB cards are responsible for signal acquisition, logical analysis, and alarm triggering. For example, smoke sensor signals trigger audible and visual alarms, which in turn shut down critical valves.

Redundancy and Fault Tolerance: Dual power supplies and hot backup ensure that critical systems (such as steering gear control) can maintain basic functionality even in the event of a single point of failure, ensuring navigational safety.

Monitoring and Alarm: Integrated functions such as fire detection, flood alarm, and oxygen supply monitoring are implemented. The PCB card’s rapid response allows for triggering a shipwide emergency shutdown or activating lifesaving equipment in emergencies.

Structural Protection: Special treatments (such as glass fiber reinforced epoxy resin sheets and nano-moisture-proof coatings) are used to resist moisture, corrosion, and salt spray, ensuring compatibility with high-humidity and high-salinity marine environments and extending equipment life.

Environmental Adaptability and Durability Design

Weather-Resistant Materials: Select highly weather-resistant PCB materials (such as FR-4 glass fiber reinforced epoxy resin and polyimide (PI)) to withstand harsh marine environments, including high salinity, high humidity, and vibration and shock. For example, chips encapsulated in ceramic or airtight plastic packages prevent moisture intrusion.

Protective Technology: Circuit boards are enhanced with conformal coatings (acrylic, polyurethane, and silicone), nano-moisture-proof coatings, and sealed structural designs (such as rubber gaskets) to enhance their waterproof and corrosion resistance and extend their service life.

Power and Energy Management

Power Regulation: Controls main engine starting, speed regulation, and auxiliary systems (such as ballast water treatment and exhaust gas scrubbers), optimizing fuel efficiency and emissions control, and supporting green technologies such as dual-fuel engines and solar hybrid systems.

Energy Monitoring: Through data collection and processing, intelligent power resource allocation is achieved, for example, ensuring a stable power supply in energy-saving motors and vibration-resistant equipment.

Comfort and Assistance Systems

Life Support: Provides circuit support for air conditioning, lighting, and entertainment systems, enhancing the comfort experience for crew and passengers. On cruise ships, intelligent control systems enable scenario-based lighting and temperature control.

Device Integration: Supports the stable operation of specialized equipment such as medical devices (e.g., electrocardiographs), security monitoring (e.g., video analysis), and financial transaction terminals (e.g., POS terminals).

Intelligence and Future Trends

Energy Saving and Environmental Protection: Integrates low-power chips and optimization algorithms to reduce ship energy consumption; supports electrical control of environmental protection equipment such as dual-fuel engines and exhaust scrubbers.

Internet of Things (IoT) Integration: Through embedded sensors and network modules, enables real-time monitoring of ship status, remote diagnosis, and predictive maintenance, promoting the development of “smart ships.”

Modular Design: Utilizes standardized modules (e.g., power modules, communication modules) to facilitate rapid maintenance and system upgrades, adapting to the evolving needs of ship technology.

Special Environmental Adaptability

Materials and Processing: High-temperature and impact-resistant PCB materials (such as polyimide substrates) are used, combined with conformal coating and a sealed structure design to resist seawater corrosion, vibration, shock, and extreme temperature fluctuations.

Technological Innovation: With the development of the Internet of Things (IoT) and intelligent technology, PCB cards are evolving towards low power consumption and high durability, supporting remote monitoring, predictive maintenance, and automated decision-making.

Summary

This PCB card is not only the “nerve center” of the ship’s electrical system but also the core support for automated, intelligent, safe, and efficient navigation. Its functions extend from basic control to data fusion, intelligent decision-making, and environmental protection and energy conservation, making it a key driver for the technological upgrade of modern ships. With technological advancements, future marine PCBs will place greater emphasis on high integration, low power consumption, strong environmental adaptability, and IoT compatibility, driving the shipbuilding industry towards a smarter and greener direction.

All products on this website are special editions, and market prices are constantly fluctuating.

Please refer to customer service for specific quotes. Since these products are new, prices are not official.

Please confirm model, product, price, and other details with customer service before placing an order. This website is used.

New products are currently available for sale, so please contact customer service.

Related product recommendations:

C3/C5 2223B001300

PAAE120306

Wartsila RM-11

NTC PAAE066001

WCS-10.04 PAAE134995

OV72H 73 REV 5

FCM-20 WARTSILA

WV32/471170.1 6 WARTSILA

QLI50 SW 1.04 WARTSILA

2V72H114 C2 WARTSILA

107.366.780.001 WARTSILA

0v72h WARTSILA

0050L289501 C7 WARTSILA

Paae067320| WARTSILA

22.23B001300 C2 WARTSILA

More……

Reviews

There are no reviews yet.