Description

Many products are not yet available. Please contact us for more information.

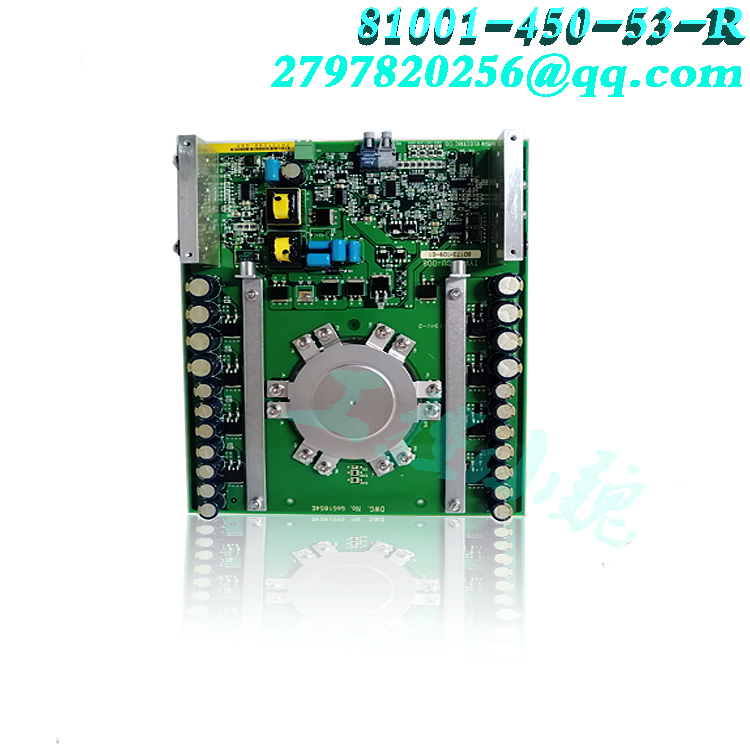

If the product model number differs from the displayed image, the model number will prevail. Please contact us for specific product images, and we will arrange for photos to be taken at the warehouse for verification.

We have 76 shared warehouses worldwide, so it may sometimes take several hours to accurately return your order. We apologize for this. Of course, we will respond to your inquiries as soon as possible.

80173-109-01 Other Names:

Input/Output Module 80173-109-01

80173-109-01 Control Unit

Processor Module 80173-109-01

Basic Functions

Signal Processing and Control: As the core control component of industrial equipment or systems, it receives input signals from various sensors (such as temperature sensors, pressure sensors, displacement sensors, etc.), amplifies, filters, converts, and processes these signals. It then analyzes and judges these signals based on preset programs and algorithms. It then processes these signals and sends control commands to the equipment’s various actuators (such as motors, valves, heaters, etc.), achieving precise control of equipment parameters such as operating status, speed, temperature, and pressure.

Data Communication and Transmission: Equipped with multiple communication interfaces, it enables data exchange and communication with other devices or a host computer. For example, the Ethernet interface enables connection to the factory LAN or the internet for remote monitoring and data transmission. Serial communication interfaces (such as RS-232 and RS-485) enable communication with devices such as PLCs and HMIs (human-machine interfaces), enabling inter-device collaboration and data sharing.

Storage: The board is equipped with memory for storing control programs, parameter settings, historical data, and other information. This memory can be flash memory or EEPROM (electrically erasable programmable read-only memory), ensuring data protection during power outages and facilitating debugging, maintenance, and troubleshooting.

Application Scenarios

Automated Production Lines: In automated production lines such as automotive manufacturing, electronics assembly, and food packaging, the 80173-109-01 motherboard module can be used to control the operation of production equipment, automating and intelligentizing the production process. For example, it can control the grabbing, handling, and placement actions of robotic arms, and control the start, stop, and speed adjustment of conveyor belts.

CNC Machine Tools: As one of the core control components of CNC machine tools, it receives commands from the CNC system, controls the movement of each coordinate axis, and achieves precise workpiece machining. It also provides real-time monitoring and protection of the machine’s operating status, ensuring safe operation.

Robot Control: In industrial and service robots, the 80173-109-01 motherboard module implements functions such as motion control, sensor data processing, and path planning, enabling robots to perform a variety of complex tasks such as welding, spraying, handling, and companionship.

Technical Features

High Reliability: Utilizing industrial-grade components and design standards, it operates stably in harsh industrial environments. Its strong anti-interference capabilities and resistance to high temperatures, humidity, and vibration ensure long-term reliable operation.

High-Performance Processing: Equipped with a high-performance processor and large-capacity memory, it can rapidly process large amounts of data and complex control algorithms, meeting the real-time and accuracy requirements of industrial control.

Flexible Scalability: A wide range of interfaces and expansion slots allow users to flexibly expand I/O points, communication interfaces, and other functions according to actual needs, facilitating system upgrades and expansion.

Easy Programming and Debugging: Support for multiple programming languages and development environments, such as ladder diagrams, instruction lists, and function block diagrams, facilitates program writing and debugging. A wide range of debugging tools and diagnostic features are also provided to quickly locate and resolve device faults.

Repair and Maintenance

Common Faults:

Component Damage: Due to prolonged operation or environmental factors (such as high temperature, humidity, and dust), electronic components on the board (such as capacitors, resistors, and chips) may age, short-circuit, or open, causing the board to malfunction.

Connection Issues: Connectors on the board may become loose or oxidized, leading to poor contact, affecting signal transmission and device operation. Furthermore, connections between the board and other devices may become disconnected or short-circuited.

Software Faults: The control program on the board may malfunction due to virus infection, software conflicts, or incorrect parameter settings, causing the device to malfunction or fail to start.

Repair Method:

Appearance Inspection: First, inspect the board visually for visible signs of component damage, burning, or deformation, as well as loose connectors or signs of oxidation. If any issues are found, replace damaged components or address any connection issues promptly.

Circuit Testing: Use a multimeter, oscilloscope, or other testing tool to test the circuits on the board, verifying that parameters such as voltage, current, and signal waveforms are normal for each component. Compare the test data with a working board to identify the fault and correct it.

Software Debugging: If a software malfunction is suspected, reinstall or upgrade the control program on the board, restore the default parameter settings, or use a professional software debugging tool to debug and repair the program..jpg)

Maintenance Recommendations:

Regular Cleaning: Clean the board regularly to remove dust and dirt and maintain proper heat dissipation. Use a dedicated electronics cleaner and brush for cleaning, but be careful to avoid using cleaners containing corrosive substances.

Anti-static Measures: When handling boards, take anti-static measures, such as wearing an anti-static wristband and using an anti-static workbench, to prevent static electricity from damaging the electronic components on the boards.

Backup Data: Regularly back up important data and programs on the boards to prevent data loss or damage that could cause equipment malfunction.

All products on this website are special products, and market prices are constantly fluctuating.

Please refer to customer service for specific quotes. Since these products are new, prices are not accurate.

Please confirm model, product, price, and other details with customer service before placing an order. This website is used.

New products are available for sale. Please contact customer service for details.

Related product recommendations:

HELITRON LP-4013.1 SCALING

HELITRON LP-1-8.2

HEINZMANN EKS-2-300-00-147-02

HEINZMANN 300-00-147-02

HDM TECH TRUNK-REV-DIP

HDM TECH CMX-128-SLC

HDM TECH CMX-128-SERVICE

HANSHIN ELECTRONICS EEC-900P-301 V1.0A

HANSHIN ELECTRONICS A4MPUA REV.4

HANLA ANN-CM5

More……

.jpg)

Payne –

Signal Processing and Control: As the core control component of industrial equipment or systems, it receives input signals from various sensors (such as temperature sensors, pressure sensors, displacement sensors, etc.), amplifies, filters, converts, and processes these signals. It then analyzes and judges these signals based on preset programs and algorithms. It then processes these signals and sends control commands to the equipment’s various actuators (such as motors, valves, heaters, etc.), achieving precise control of equipment parameters such as operating status, speed, temperature, and pressure.

Data Communication and Transmission: Equipped with multiple communication interfaces, it enables data exchange and communication with other devices or a host computer. For example, the Ethernet interface enables connection to the factory LAN or the internet for remote monitoring and data transmission. Serial communication interfaces (such as RS-232 and RS-485) enable communication with devices such as PLCs and HMIs (human-machine interfaces), enabling inter-device collaboration and data sharing.

Storage: The board is equipped with memory for storing control programs, parameter settings, historical data, and other information. This memory can be flash memory or EEPROM (electrically erasable programmable read-only memory), ensuring data protection during power outages and facilitating debugging, maintenance, and troubleshooting.

https://www.weikunfadacai1.com/product/mitsubishi-gu-d08-80173-109-01-motherboard-module-80173-109-01/