Description

Many products have not been listed yet. For more products, please contact us

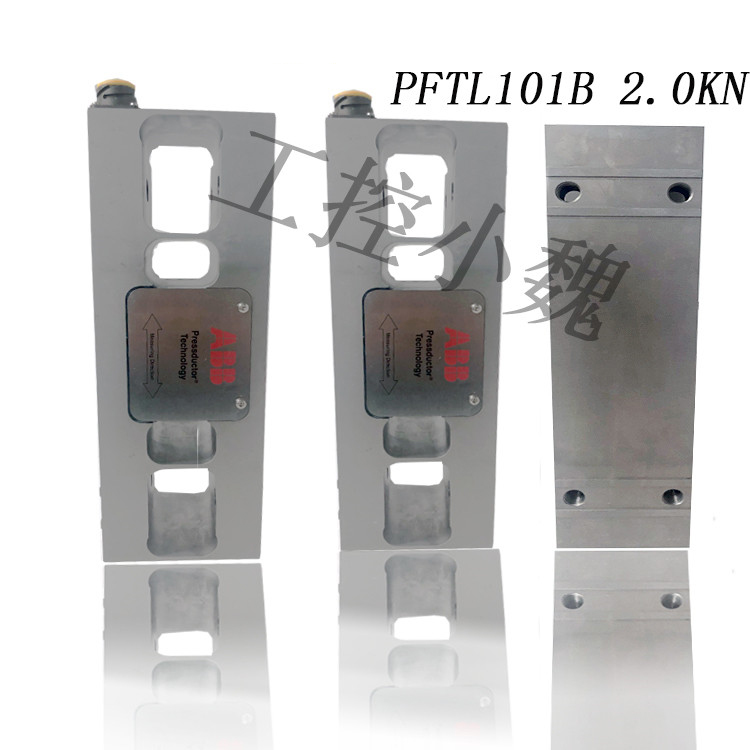

If the product model is inconsistent with the displayed image, the model shall prevail. Please contact us for specific product images, and we will arrange for photos to be taken and confirmed in the warehouse

We have 16 shared warehouses worldwide, so sometimes it may take several hours to accurately return to you. We apologize for any inconvenience caused. Of course, we will respond to your concerns as soon as possible.

PFTL201C 50KN 3BSE007913R50 Other names:

Tension spare parts PFTL201C 50KN 3BSE007913R50

PFTL201C 50KN 3BSE007913R50 tension controller

Tension sensor PFTL201C 50KN 3BSE007913R50

PFTL201C 50KN 3BSE007913R50 tension measuring meter

Tensiometer PFTL201C 50KN 3BSE007913R50

PFTL201C 50KN 3BSE007913R50 pressure gauge

PFTL201C 50KN 3BSE007913R50 pillow type sensor (commonly referred to as pillow block tension controller) is a high-performance tension control device with various characteristics and advantages, suitable for various production environments.

This sensor is based on hardware technology and a high-performance analog signal processor control scheme, which can provide higher performance and lower price. Its response time is very fast, just press the button to automatically complete the entire tension control process, without the need for manual operation. In addition, its operating temperature range is also very wide, and it can operate normally in environments ranging from -40 ° C to+85 ° C, which means that it can maintain stable performance even in harsh environments..jpg)

During the material conveying process, the PFTL201C 50KN 3BSE007913R50 pillow type sensor can achieve non impact and non friction conveying of materials through tension control, avoiding production interruptions caused by conveyor belt breakage and other situations. At the same time, it can also ensure the smoothness and stability of materials during the production process, making the production system more stable..jpg)

When unexpected situations occur during material operation, this sensor also has the function of automatically cutting off the power to protect the equipment and materials from damage. In addition, its installation and maintenance are also very simple, only three screws are needed to fix it to achieve stable and reliable installation of the tension control system, and there is no need to change any settings throughout the entire process.

Especially in the following areas:

The printing and packaging industry: In printing and packaging equipment, tension controllers are used to ensure that rolls (such as paper, film, etc.) maintain appropriate tension throughout the entire production process to avoid stretching, warping, or other problems.

Textile industry: In textile machinery, especially in processes such as weaving and stretching ropes, tension controllers can be used to ensure that the yarn or rope maintains appropriate tension during the processing, in order to achieve better product quality.

Metal processing: In the metal processing process, such as the uncoiling and cutting of coils, the tension controller can ensure that the metal strip or sheet maintains appropriate tension during processing to avoid deformation or damage.

In addition, the PFTL201C 50KN 3BSE007913R50 pillow sensor also has the following characteristics:

High performance: Control solutions based on hardware technology and high-performance analog signal processors can provide higher performance and lower prices.

Quick response time: Simply press the button to automatically complete the entire tension control process without the need for manual operation.

Wide working temperature range: working temperature -40 ° C~+85 ° C, can work normally in harsh environments.

Easy installation and maintenance: The tension control system can be installed stably and reliably with only three screws, without the need to change any settings throughout the entire process.

Easy to integrate: It can be easily integrated with other systems such as PLC or D #.

By precisely controlling the tension, it can achieve material transportation without impact and friction, thus avoiding problems such as broken conveyor belts during production.

Tension control makes the production system more stable, ensuring the smoothness and stability of materials during the production process, thereby improving the operational efficiency of the production line..jpg)

This controller is based on hardware technology and a high-performance analog signal processor control scheme, which can provide higher performance and lower price. Its fast response time allows the entire tension control process to be automatically completed by simply pressing a button, without the need for manual operation.

All products on this website are special products, and market prices have been fluctuating,

The specific customer service quotation shall prevail, as the product is a new product and the price is not genuine,

Please confirm the model, product, price, and other detailed information with customer service before placing an order. The website has been used,

The new one is for sale, please contact customer service to communicate.

Model recommendation:

PFTL 201C-10.0

PFTL 201CE-10.0

PFTL 201C-20.0

PFTL 201CE-20.0

PFTL 201C-50.0

PFTL 201CE-50.0

PFTL 201D-50.0

PFTL 201DE-50.0

PFTL 201D-100.0

PFTL 201DE-100.0

More……

-300x300.jpg)

-300x300.jpg)

admin –

This sensor is based on hardware technology and a high-performance analog signal processor control scheme, which can provide higher performance and lower price. Its response time is very fast, just press the button to automatically complete the entire tension control process, without the need for manual operation. In addition, its operating temperature range is also very wide, and it can operate normally in environments ranging from -40 ° C to+85 ° C, which means that it can maintain stable performance even in harsh environments.