Description

Many products are not yet available. Please contact us for more information.

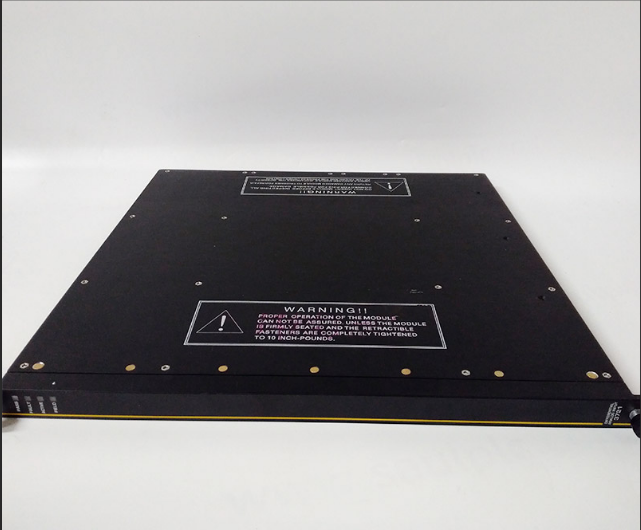

If the product model number differs from the displayed image, the model number will prevail. Please contact us for specific product images, and we will arrange to take photos at the warehouse for verification.

We have 76 shared warehouses worldwide, so it may sometimes take several hours for us to accurately return your product. We apologize for this. Of course, we will respond to your inquiries as soon as possible.

3623T Other Names:

Redundant Controller Module 3623T

3623T Communication Module

Digital Module 3623T

The Triconex 3623T is a core component of Schneider Electric’s Tricon Safety Instrumented System (SIS). It is a digital output (DO) module with a triple modular redundant (TMR) architecture, designed for high-risk industrial environments and meeting the SIL3 safety level (IEC 61508 standard).

TMR Technology Principle: Using a triple redundant design, three independent submodules perform the same task in parallel, achieving fault tolerance through a “2oo3” (two out of three) voting mechanism. If a single module fails, the system automatically disables the faulty module, allowing the remaining modules to continue operating, ensuring uninterrupted operation for 72 hours.

Redundancy Design: The TMR architecture achieves triple redundancy, with dual power supplies (either of which can independently support the full rack load), hot-swappable and online power supply replacement support, and IEC 61508 SIL 3 safety certification, making it suitable for SIS (Safety Instrumented Systems) and ESD (Emergency Shutdown Systems).![]()

Interface and Communication: Compatible with the Tricon system bus, it supports real-time fault monitoring and channel status indication (PASS/FAULT/ACTIVE indicators), and data voting and diagnostic information transmission via the TriBus bus.

Technical Specifications and Features

Electrical Parameters:

Rated voltage: 120VDC (supports a wide range of DC 24V-120V and AC 48V-230V), maximum single-point current of 0.8A, and isolation voltage of 1500VDC/2500VDC.

Communication Interfaces: TriBus high-speed bus, Ethernet (10/100Base-TX), RS-232, supporting Modbus TCP, OPC, and other protocols.

Performance:

Processor: 32-bit RISC CPU, standard 8MB Flash/SRAM (expandable).

Scan Cycle: 50-200ms (depending on program complexity).

Operating Temperature: 0°C to 60°C, Storage Temperature: -40°C to 85°C.

Safety and Diagnostics:

Built-in self-diagnostics monitor CPU status, memory, power supply voltage, and communication status in real time.

Hot-swappable, faulty modules can be replaced online, with the new module automatically synchronizing data.![]()

TÜV certified, compliant with ISA 84.01 and IEC 61508 standards.

Application Scenarios and Industry Compatibility

Core Applications:

Safety Instrumented Systems (SIS): Emergency Shutdown (ESD), burner management, fire and gas detection (F&G), and turbine control. Key control scenarios: valve control, motor start/stop, contactor drive, and solenoid valve operation.

Industry coverage:

High-risk industries such as oil and gas, chemicals, electric power, nuclear power, water treatment, metal processing, food and beverage, and pharmaceuticals.

Typical cases: Emergency shutdown of petrochemical plants and leak detection and isolation of oil and gas pipelines.

Advantages and Differentiators

High reliability: The TMR architecture ensures that single-point failures do not cause system failure, with a mean time between failures (MTBF) exceeding 1 billion hours.

Flexibility:

Supports online programming (TriStation 1131 software, compliant with IEC 61131-3) for dynamic logic modification.

Modular design with expandable I/O channels up to 730,000 points, adapting to plants of varying sizes.

Easy maintenance:

Status indicators (RUN/ACTIVE/MAINT/DIAG/PWR) intuitively display operating status.

Automatic fault recovery and remote diagnostics reduce the risk of downtime.

Compatibility: Integrates with DCS and AMS systems, supports OPC UA data exchange, and adapts to the needs of the Industrial Internet of Things.![]()

Maintenance and Reliability

Fault Diagnosis: Built-in self-diagnostic circuitry (such as I/O loop detection and power loss detection) allows real-time monitoring of module status, system event collection, and rapid replacement of faulty modules through EnDM software.

Power Management: Dual redundant power supply design with automatic switchover in the event of a single power failure. An alarm is triggered when the temperature exceeds 60°C, and a backup battery supports independent operation for over six months.

Maintenance Standards: Regularly check the cabinet environment and module indicator lights (such as power, communication, and channel activation lights), promptly replace faulty fuses, and analyze system logs using software tools to identify potential problems.

Specification Expansion and Compatibility

Compatible Modules: Compatible with other Triconex series modules (such as the 3503E digital input, 3805E analog output, and 4118 communication module), and supports expansion rack configurations (such as the 8306A power module and 8101 expansion rack). Physical Features: The module’s dimensions conform to standard rack specifications, supports hot-swappable operation, and features a status indicator and fault alarm contacts (NC/NO relay outputs) on the front panel.

Certifications and Standards

Complies with international safety standards such as IEC 61508 SIL 3 and ISO 13849, and is FCC and CE certified for use in explosion-proof areas (such as Ex i intrinsically safe design).

The Triconex 3623T TMR 120VDC monitoring DO module, with its TMR architecture, SIL 3 safety rating, and flexible expansion capabilities, is a key component for ensuring production safety and continuous operation in high-risk industrial scenarios.

All products on this website are special offers, and market prices are constantly fluctuating.

Please refer to customer service for specific quotes. Since these products are new, prices may not be accurate.

Please confirm model, product, price, and other details with customer service before placing an order. This website is used.

New products are for sale. Please contact customer service for details.

Related product recommendations:

ICS TRIPLEX TC-011-02-2M5

ICS TRIPLEX TC-801-02-4M5

ICS TRIPLEX TC-314-02-2M5

TRICONEX 8405N

TRICONEX 4609

TRICONEX 3805E

TRICONEX 3708EN

More……

admin –

The Triconex 3623T is a core component of Schneider Electric’s Tricon Safety Instrumented System (SIS). It is a digital output (DO) module with a triple modular redundant (TMR) architecture, designed for high-risk industrial environments and meeting the SIL3 safety level (IEC 61508 standard).

TMR Technology Principle: Using a triple redundant design, three independent submodules perform the same task in parallel, achieving fault tolerance through a “2oo3” (two out of three) voting mechanism. If a single module fails, the system automatically disables the faulty module, allowing the remaining modules to continue operating, ensuring uninterrupted operation for 72 hours.

The Triconex 3623T is a core component of Schneider Electric’s Tricon Safety Instrumented System (SIS). It is a digital output (DO) module with a triple modular redundant (TMR) architecture, designed for high-risk industrial environments and meeting the SIL3 safety level (IEC 61508 standard).

TMR Technology Principle: Using a triple redundant design, three independent submodules perform the same task in parallel, achieving fault tolerance through a “2oo3” (two out of three) voting mechanism. If a single module fails, the system automatically disables the faulty module, allowing the remaining modules to continue operating, ensuring uninterrupted operation for 72 hours.