Description

Many products are not yet listed. Please contact us for more product information.

If the product model differs from the displayed image, the model number shall prevail. Please contact us for specific product images; we will arrange to take photos in our warehouse for confirmation.

We have 76 shared warehouses worldwide, so it may sometimes take several hours to accurately return the information to you. We apologize for any inconvenience. Of course, we will respond to your inquiries as soon as possible.

Other names for CIM 3211:

Communication Gateway Module CIM 3211

CIM 3211 Communication PLC Module

Redundant Module CIM 3211

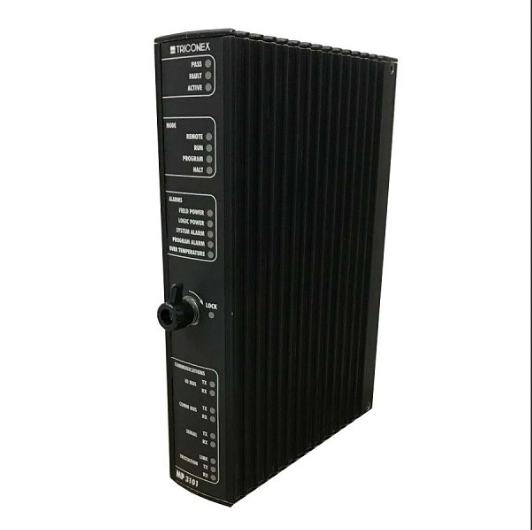

The Triconex CIM 3211 (model CIM3211S2) is the core communication interface module of the Triconex Safety Instrumented Systems (SIS) under Schneider Electric (formerly Invensys). It is designed specifically for industrial safety-critical scenarios, featuring high reliability, multi-protocol compatibility, and redundant communication capabilities. It complies with the IEC 61508 SIL 3 safety certification standard and is widely used in high-risk industries such as petroleum, chemical, power, and metallurgy.

Module Positioning: The CIM 3211 (e.g., CIM3211S2) is a communication interface module in the Triconex series, specifically designed for Industrial Safety Instrumented Systems (SIS), supporting multi-protocol data communication and system integration.

Technical Specifications and Features

Communication Protocol Support:

Compatible with industrial protocols such as Modbus RTU, Profibus DP, Ethernet/IP, and DeviceNet, supporting networking with DCS, PLC, host computers, and third-party devices (such as HART devices).

Supports redundant communication channel configuration to ensure reliable data transmission.![]()

Electrical Parameters:

Power Requirements: Typically 24V DC, adaptable to industrial power fluctuation environments.

Operating Temperature: -20°C to +60°C (up to -40°C to +85°C in some scenarios), meeting the requirements of harsh industrial environments.

Mechanical and Compatibility:

Rack-mount/modular installation, compatible with Triconex series controllers (e.g., Tricon, Tricon CX), I/O modules, and processor modules. Supports hot-swapping and online module replacement, reducing downtime.

Diagnostic Functions: Built-in self-diagnostic module monitors communication status and line faults (such as open circuits/short circuits) in real time, providing feedback via LED indicators (input/output status, fault alarms). Supports remote monitoring and fault location via software (such as TriStation 1131, SOE Reader).

Safety Certifications:

Complies with IEC 61508/61511 standards, SIL3 certified, suitable for high-risk fields such as petrochemicals, nuclear power, and rail transportation.

Application Scenarios and Industry Value:

Industrial Automation:

In industries such as petrochemicals, power, and metallurgy, it serves as the communication hub of SIS/ESD systems, enabling functions such as emergency shutdown, process interlocking, and fire and gas monitoring (F&G).

Integrated into DCS/PLC systems, supporting data sharing and remote monitoring (such as SCADA systems).

Critical Infrastructure:

Infrastructure Applications:Ensuring equipment safety interlocking and fault self-diagnosis in scenarios such as rail transit signaling systems, gas turbine control, and compressor anti-surge control.

System Advantages:

Triple Redundancy (TMR): Achieving fault-tolerant control through three independent parallel systems; a single point of failure does not affect overall operation, achieving 99.9998% system availability.

Self-Diagnosis Capability: Built-in fault detection and alarm functions, supporting module-level status monitoring and remote maintenance.

Scalability: Supports flexible expansion of I/O cards and communication modules, adapting to the needs of control systems ranging from small to large.

Functional Applications:

Core Role:Serving as the communication hub of the Triconex SIS system, connecting the main controller with I/O modules, host computers, or third-party devices to achieve control command transmission, equipment status feedback, and data acquisition. For example, in chemical plants, it can link with emergency shutdown (ESD) systems and fire alarm controllers to ensure rapid response of safety interlock actions.

System Advantages:

Triple Redundancy (TMR): Achieving fault-tolerant control through three independent parallel systems; a single point of failure does not affect overall operation, achieving 99.9998% system availability.

Self-Diagnosis Capability (SDC): Self-diagnostic capability; built-in fault detection and alarm functions; supports module-level status monitoring and remote maintenance.

Scalability: Supports flexible expansion of I/O cards and communication modules, adapting to the needs of control systems ranging from small to large.

Functional Applications:

Core Role: Serving as the communication hub of the Triconex SIS system, connecting the main controller with I/O modules, host computers, or third-party devices to achieve control command transmission, equipment status feedback, and data acquisition. For example, in chemical plants, it can link with emergency shutdown (ESD) systems and fire alarm controllers to ensure rapid response of safety interlock actions Expansion Capabilities: Supports expanded chassis configurations, connecting up to 100 I/O modules with a communication distance of 30 meters (standard configuration) or 12 kilometers (via the RXM chassis), meeting the cabling needs of large industrial sites.

Typical Scenarios: Widely used in safety instrumented systems in industries such as oil and gas transportation, nuclear power plants, and pharmaceuticals, as well as in building automation and process control (e.g., temperature/pressure monitoring, valve control), ensuring high system availability and data consistency.

Installation and Configuration:

Hardware Installation: Must be installed inside a control cabinet, secured with DIN rails. Wiring must follow the non-polarized two-wire bus specification. Input lines must be terminated with a 10kΩ resistor in parallel. Output line load should not exceed DC32V/1.5A/30ms. Avoid disconnecting the controlled equipment for testing (otherwise, an “output line fault” alarm will be triggered).

Software Configuration: Logic programming and variable configuration are performed using TriStation 1131 software, supporting online modification of alarm and interlock values. SOE Reader software analyzes event sequences, and the diagnostic software (Enhanced Diagnostic Monitor) monitors module health status in real time, clearing faults or contacting the manufacturer to analyze complex issues.

Maintenance Recommendations: Regularly check communication link stability, update firmware versions, and use dedicated tools (such as handheld electronic encoders) for module coding and testing to ensure compliance with national standards such as GB 16806-2006.

Compatibility Considerations: Pay attention to system version updates and protocol compatibility to avoid incompatibility with older devices; when integrating third-party systems, verify the accuracy of protocol conversion and data mapping.

The Triconex CIM 3211, with its high safety standards, multi-protocol compatibility, and redundant design, is a key component of industrial safety control systems, suitable for complex industrial scenarios requiring highly reliable communication and rapid response.

Please note that all products on this website are specialty items, and market prices are constantly fluctuating.

Please refer to customer service for a specific quote, as the price may not be accurate for new products.

Please confirm the model, product, price, and other details with customer service before placing an order. This website is currently in use.

New items are available for sale; please contact customer service for further information.

Related product recommendations:

ICS TRIPLEX TC-011-02-2M5

ICS TRIPLEX TC-801-02-4M5

ICS TRIPLEX TC-314-02-2M5

TRICONEX 8405N

TRICONEX 4609

TRICONEX 3805E

TRICONEX 3708EN

More……

admin –

The Triconex CIM 3211 Invensys communication interface module is compatible with industrial protocols such as Modbus RTU, PROFIBUS DP, Ethernet/IP, and DeviceNet. It supports networking with DCS, PLC, host computers, and third-party devices (such as HART devices), and supports redundant communication channel configuration to ensure reliable data transmission. It features rack-mount/modular installation and is compatible with Triconex series controllers (such as Tricon and Tricon CX), I/O modules, and processor modules. It supports hot-swapping and online module replacement, reducing downtime. In industries such as petrochemicals, power, and metallurgy, it serves as the communication hub for SIS/ESD systems, enabling functions such as emergency shutdown, process interlocking, and fire and gas monitoring (F&G). Integrated into DCS/PLC systems, it supports data sharing and remote monitoring (such as SCADA systems). Fault-tolerant control is achieved through three independent parallel systems; a single point of failure does not affect overall operation, achieving a system availability of 99.9998%. It features built-in fault detection and alarm functions, supports module-level status monitoring and remote maintenance, and allows for flexible expansion of I/O cards and communication modules, adapting to the needs of control systems ranging from small to large.

https://www.weikunfadacai1.com/product/triconex-cim-3211-invensys-communication-interface-module-cim-3211/