Description

Many products are not yet available. Please contact us for more information.

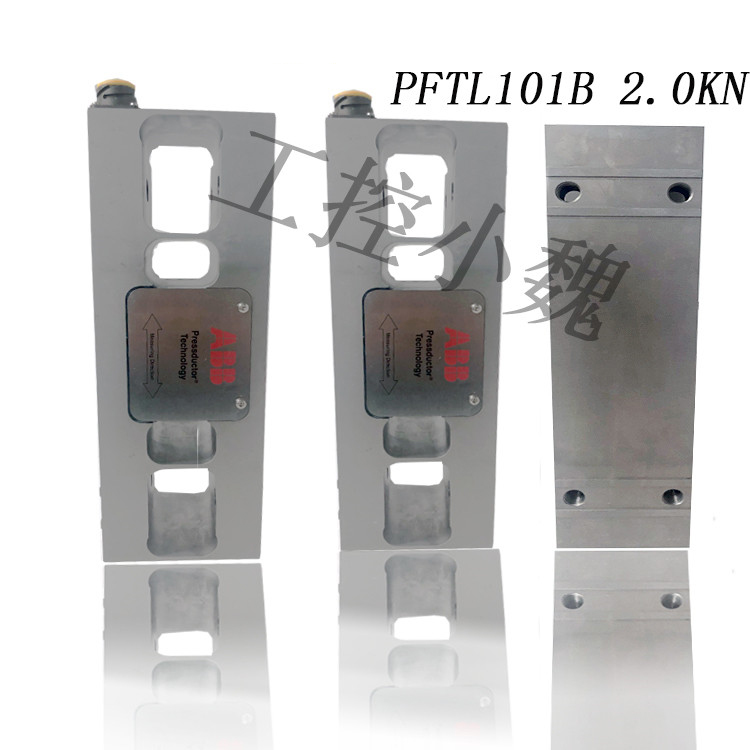

If the product model number differs from the displayed image, the model number will prevail. Please contact us for specific product images, and we will arrange to take photos at the warehouse for verification.

We have 76 shared warehouses worldwide, so it may sometimes take several hours for us to accurately return your product. Please understand. We will, of course, respond to your inquiries as soon as possible.

Other names for the PFCL201CE 50KN 3BSX802939-108:

Load Cell PFCL201CE 50KN 3BSX802939-108

PFCL201CE 50KN 3BSX802939-108 Pillow-Type Load Cell

PFCL201CE 50KN 3BSX802939-108 Load Cell

The PFCL201CE 50KN 3BSX802939-108 tension sensor unit is manufactured by ABB and belongs to the PFCL series tension controller, model PFCL201CE. It has a rated control capacity of 50 kN and is suitable for web tension control applications (such as textiles, paper, and metal processing).

Core Parameters:

Measuring Range: 0-50kN (vertical force measurement), accuracy up to ±0.5%FS, supports closed-loop tension control.

Output Signal: Analog (±10V/4-20mA) or digital bus (Profibus-DP, Modbus, Ethernet/IP), compatible with industrial automation systems.

Protection Rating: IP66/IP67, suitable for harsh environments such as high temperature, high humidity, and dust (such as steel mills and paper mills).

Structural Features: Made of one-piece stainless steel, impact- and corrosion-resistant, supports quick installation (such as terminal connections, connectors, and bearing seat integration).

Output Method: Voltage (0.5-6VDC), current, or digital signal (such as RS485)..jpg)

Power Requirements: Typically 10-30VDC, power consumption <15mA.

Accuracy and Linearity: Nonlinearity <1%FS, stable temperature characteristics.

High-Precision Control: Supports closed-loop and open-loop control modes, precisely adjusting tension to 0.1% full-scale accuracy.

Compatibility: Compatible with a variety of sensors (such as strain gauge and Hall effect sensors), supports industrial protocols such as Profibus and Ethernet/IP, and can be linked with PLCs and drives.

Environmental Adaptability: With an IP67 rating, it withstands temperatures of -10°C to 60°C, dust, and humidity, making it suitable for continuous operation in printing presses and film production lines.

Dynamic Response: Response frequency >1kHz, providing real-time feedback on tension changes to prevent material slack or breakage.

Applications

Textile Industry: Controls yarn/fabric tension to ensure uniform winding and reduce the risk of wire breakage.

Packaging and Printing: Monitors the tension of paper and plastic film to prevent wrinkling and stretching.

Metalworking: Maintains stable tension during straightening and stretching processes to prevent material deformation.

Cable Manufacturing: Controls copper wire drawing tension to ensure consistent wire diameter.

Robotics: Integrated into the end-cap of collaborative robots, enabling flexible gripping (e.g., fragile items).

Material Processing: Tension monitoring during the winding/slitting process of metal foil, plastic film, and paper.

Industrial Automation: Closed-loop tension control in printing presses, packaging machines, and wire and cable production lines.

Case Studies:

Real-time monitoring of coil tension in rewinders allows for stable speed and pressure adjustments to prevent material deformation or damage.

In rolling mills, it is linked with the drive and brake to dynamically adjust strip tension and optimize production efficiency.

Installation and Maintenance Guide

Installation Key Points:

Power Supply: The main power supply must be 200-250V AC/50-60Hz, with a 250mA fuse (time lag). Ensure reliable grounding.

Wiring Specifications: Signal cables must be ≥30cm apart from power cables, and the shielding layer must be grounded at the controller to prevent electromagnetic interference.

Mechanical Installation: Ensure the sensor is securely connected to the measured object, with the force applied aligning with the sensor axis (deviation <0.5°) to avoid additional stress.

Operational Recommendations

Technical Verification: If actual use is required, zero calibration (no-load condition) and full-scale calibration (suspending a known weight) are recommended to ensure measurement accuracy.

Maintenance Precautions: Avoid strong electromagnetic interference and condensation at high temperatures. Regularly inspect sensor wiring and mechanical structure for wear.

All products on this website are special products, and market prices fluctuate.

Please refer to customer service for specific quotes. Since these products are new, prices are not official.

Please confirm model, product, price, and other detailed information with customer service before placing an order. This website is used.

New products are for sale. Please contact customer service for details.

Related product recommendations:

PFCL201CE 3BSE006699D0005

PFCL201CE-150 KN 3BSE006699D0005

PFVA 131 3BSE007126R1

PFVA401 3BSE018732R1

PFXA401SF 3BSE024388R4

HIEE400995R0002-3004223

PFEA111-20 Tension controller

PFEA111-20 3BSE050090R20

PFEA111-65 3BSE028140R0065

PFEA111-65 Tension controller

PFEA112-20 Tension controller

PFEA112-20 3BSE030369R0020

PFEA112-20 3BSE050091R20

PFEA112-20 3BSE050091R20 3BSE030369R0020

PFEA112-65 Tension controller

PFEA112-65 3BSE030369R0065

CI867AK01 3BSE043660R1

CI873K01 3BSE058899R1

CI535V26 3BSE022161R1

PFSA103B 3BSE002487RCI869K01 3BSE049110R1

QGPR 104/102

3BSE025344R0101 PFVL 141R

PFVL141R 3BSE025344R0101

3BSE025094R2500

PFVL141V 3BSE025094R2500

3BSX670292-112

PFVL141 3BSX670292-112

PFVL141

PFCL201CE 3BSE006699D0005

PFCL201CE-150 KN 3BSE006699D0005

PFEA113-2 3BSE028144R0020

PFSA103B 3BSE002487R1

ABB PFSK110 57310001-HG

ABB PFSK108 YM322001-EH

More……

.jpg)

.jpg)

Reviews

There are no reviews yet.